What Are the Most Common Metals Used in Die Casting?

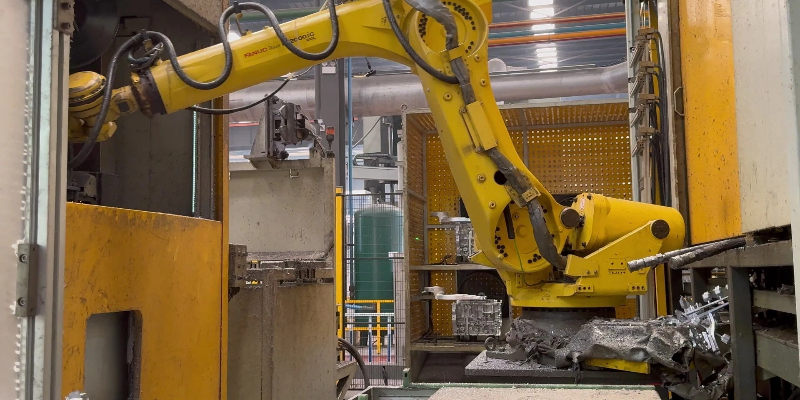

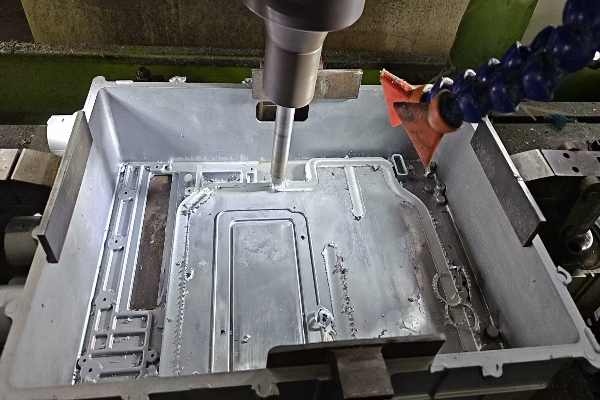

Choosing the wrong metal for your component can be a costly mistake. It leads to parts that are too heavy, too weak, or unable to withstand their operating environment, sending you back to the drawing board. The most common metals for die casting1 are aluminum2, zinc3, and magnesium4. Aluminum dominates automotive and industrial applications for […]