Seeing inconsistent part quality and not knowing why? It’s frustrating to blame the machine or the alloy when the root cause might be the tool itself. The mold is where quality begins.

Yes, the die casting mold1 is the single most critical factor determining product quality2. It dictates the final part’s dimensional accuracy3, surface finish4, and internal soundness by controlling how molten metal flows, cools, and solidifies. Essentially, the part is a direct reflection of the mold’s precision and health.

A high-quality die casting mold is a significant investment, and I’ve had many procurement directors ask me if the high cost is truly justified. My answer is always the same: absolutely. In my two decades of experience, from the shop floor to consulting with global Tier 1s, I’ve seen firsthand how a superior mold delivers a superior part, cycle after cycle. A poorly designed or maintained mold is a guarantee of future headaches, scrap, and cost overruns5. The quality of your final product is quite literally born from the quality of the steel mold.

How Does Mold Design Affect Surface Finish and Dimensional Accuracy?

Your parts have cosmetic flaws requiring costly rework or don’t fit together during assembly. This leads to production delays6, unsatisfied clients, and a damaged reputation for quality and reliability.

The mold’s design directly dictates the part’s final form. The polished surface inside the mold cavity is mirrored onto the part’s exterior, while the precision of its cores, slides, and alignment determines the final dimensional accuracy and tolerance.

When a customer specifies a "Class A" surface finish for an automotive interior part or tight tolerances for an electronics enclosure, they are really specifying the quality of our mold. The part can never be more precise than the tool that creates it. It all comes down to a few core design principles that we obsess over.

First is the surface finish of the mold cavity itself. To get a smooth, flawless part, we must polish the steel cavity to a mirror finish. Any scratch or imperfection in the steel will be perfectly replicated on every single part that comes out of it.

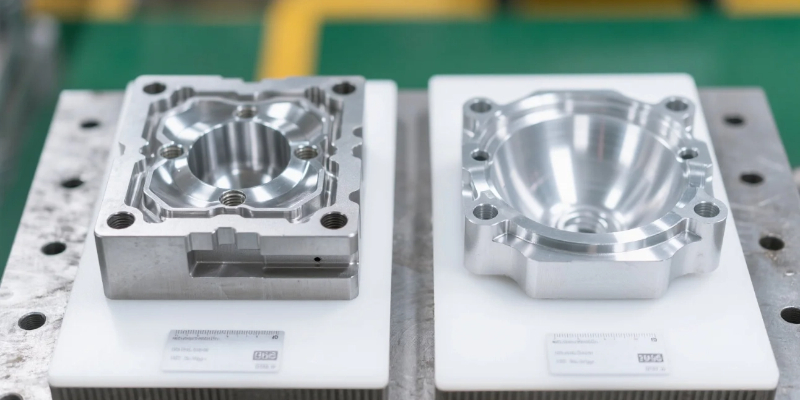

Second is dimensional accuracy. A mold isn’t one solid block of steel. It’s a complex assembly of moving parts like slides and cores that create the part’s intricate features. The precision of how these components fit and align is what allows us to hold tolerances measured in microns.

| Mold Design Feature | Impact on Part Quality | My Experience |

|---|---|---|

| Cavity Polishing | Directly determines the smoothness and cosmetic appearance. | A car’s dashboard trim needs a flawless finish, which starts with days of hand-polishing the steel. |

| Draft Angles | Prevents drag marks and scratches during part ejection. | Without a proper draft, parts get damaged on removal, leading to high scrap rates7. |

| Parting Line | Minimizes the visible seam and prevents flash (excess material). | For EV connector housings, a clean parting line is essential for proper sealing. |

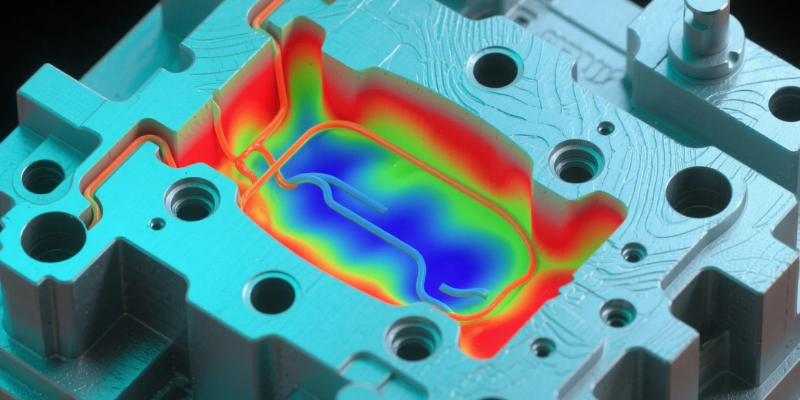

What Is the Role of Thermal Balance in Preventing Casting Defects?

You constantly see defects like shrinkage porosity or warpage. You try adjusting machine settings, but the problems persist, causing high scrap rates and missed deadlines while you chase symptoms.

The mold’s thermal balance8, managed by a network of cooling channels, is critical. It ensures the molten metal solidifies uniformly across the part. Proper control prevents defects like shrinkage, warpage, and cold shuts by managing the rate and direction of heat removal.

I often tell my engineers to stop thinking of a mold as just a container. It’s a high-performance heat exchanger. We inject aluminum at around 660°C into a steel die that we maintain at around 200°C. Our job is to pull that heat out in the most controlled and strategic way possible. If we fail, defects are guaranteed.

If a section of the mold gets too hot (a "hot spot"), the metal there will be the last to cool. As it shrinks, there’s no more liquid metal to fill the void, creating shrinkage porosity deep inside the part. This is a structural killer. On the other hand, if a section is too cold, the molten metal can freeze too early, causing "cold shuts" where two fronts of metal meet but fail to fuse together property. This is a common cause of leaks in pressure-tight housings. For a complex inverter housing we developed, we used advanced mold flow simulation to design the cooling channels. We even used special "conformal cooling9" lines that followed the part’s contour to ensure every section cooled at the exact right speed.

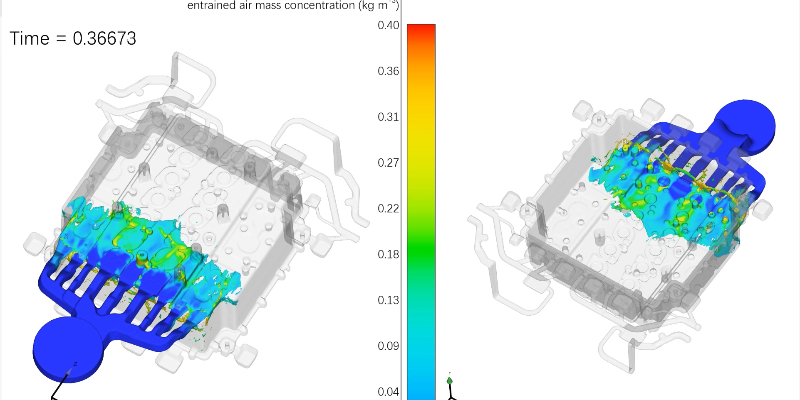

How Does Optimizing Gating and Venting Systems Reduce Porosity?

Your parts are failing leak tests because of internal gas porosity. It’s incredibly frustrating to scrap expensive components that look absolutely perfect on the outside, a hidden defect that costs you dearly.

The gating system10 acts as the entryway for the molten metal, designed for smooth flow. The venting system11 is the exit for trapped air. Optimizing both—a good front door and a clear back door—is the key to preventing the metal from trapping gas.

When we analyze porosity, I use a simple analogy. Think of the gating system as the front door and the venting system as the emergency exit. Both must be designed perfectly for a defect-free part.

The gating system, which includes the runner and the gate, controls how the molten aluminum enters the mold cavity. A bad design is like turning on a firehose at full blast; the flow is violent and turbulent, churning air into the metal and creating gas bubbles. Our goal is to design a gate that fills the part quickly but smoothly, like pouring wine down the side of a glass. We use mold flow simulation to perfect this design before we ever cut steel.

The venting system is just as critical. The mold cavity is full of air before the shot. That air has to escape in milliseconds. Vents are very thin channels, usually only 0.15mm deep, that are big enough for air to get out but too small for the thicker molten aluminum to pass through. If the vents are too small or in the wrong place, air gets compressed, trapped, and becomes gas porosity.

How Does Mold Material Selection Influence Tool Life and Part Quality?

Your mold is failing prematurely, or you notice part quality degrades after 100,000 shots. This unplanned downtime for repairs is expensive, and product inconsistency risks your relationship with your customer.

Using premium tool steel, like H13, is essential for resisting thermal fatigue (heat checking12) and erosion13 from the molten aluminum. The right material ensures the mold maintains its integrity over hundreds of thousands of cycles, guaranteeing consistent part quality and long tool life14.

A die casting mold lives a brutal life. It endures massive thermal shocks—from 200°C to 660°C and back again—every 30 to 60 seconds. It also withstands immense pressure. This extreme environment will destroy inferior materials. Choosing the right steel and heat treatment isn’t an option; it’s a requirement for long-term projects like the ones we handle for automotive OEMs.

There are two main ways a mold fails due to poor material choice. The first is heat checking, where the constant expansion and contraction create a network of fine cracks on the mold surface. These cracks are then transferred to every part, ruining the surface finish. The second is erosion, where the high-velocity flow of molten aluminum literally wears away the steel, especially around the gate. This changes the dimensions of the part over time, leading to inconsistent quality. To prevent this, we use high-grade, certified tool steels and a very precise heat treatment process to give the steel the best combination of hardness (to resist wear) and toughness (to resist cracking). It’s an upfront investment that prevents much larger costs down the road.

Conclusion

The mold is the heart of the die casting process. Its design, thermal management, and material composition are not just related to part quality—they define it. Investing in a superior mold is investing in quality itself.

-

Understanding the role of die casting molds can significantly enhance your product quality and manufacturing efficiency. ↩

-

Exploring product quality in manufacturing can help you identify key areas for improvement and innovation. ↩

-

Learn about the critical factors affecting dimensional accuracy to ensure your products meet specifications. ↩

-

Discover how surface finish impacts the aesthetic and functional quality of your die cast products. ↩

-

Understanding cost overruns can help you manage budgets effectively and ensure project success. ↩

-

Identifying causes of production delays can help streamline your processes and improve delivery times. ↩

-

Reducing scrap rates is essential for cost efficiency and improving overall production quality. ↩

-

Understanding thermal balance can help you prevent defects and improve the overall quality of your cast parts. ↩

-

Understanding conformal cooling can help you optimize your mold design for better thermal management. ↩

-

Learn how an optimized gating system can enhance the flow of molten metal and improve part quality. ↩

-

Understanding the venting system’s role can help you design molds that minimize defects and improve quality. ↩

-

Understanding heat checking can help you select better materials and design molds that last longer. ↩

-

Learn about erosion’s impact on mold performance to ensure consistent part quality over time. ↩

-

Exploring tool life factors can help you make informed decisions about mold materials and maintenance. ↩