Electric Vehicle Parts Die-cast lightweight Electric vehicle component housings to...

Learn MoreFriction welding enables seamless Al-steel bonding (joint strength ≥90% base metal ), ideal for EV hybrid-material housings.

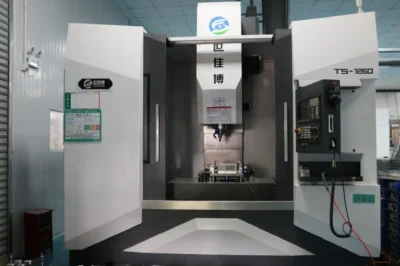

Tooling longevity exceeds 300k cycles with ±0.05mm tolerance . AI-optimized gating systems enable rapid mold changeovers (<15 mins) for custom parts.

Pioneering 1.2mm thin-wall casting (industry avg. 1.8mm) achieves 25% weight reduction while maintaining 200+ Nm structural rigidity for EV lightweighting.

14-stage inspection protocol with 100% X-ray coverage , compliant with IATF 16949 & NADCA standards for defect-free deliverables.

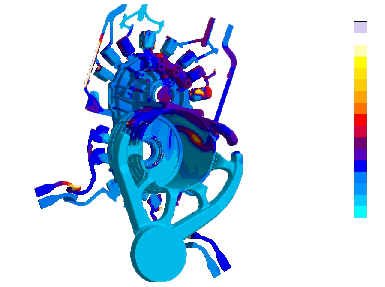

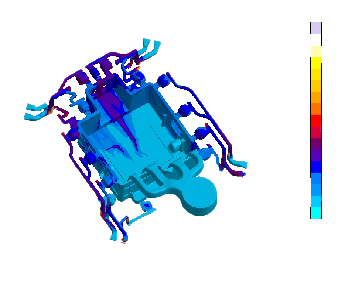

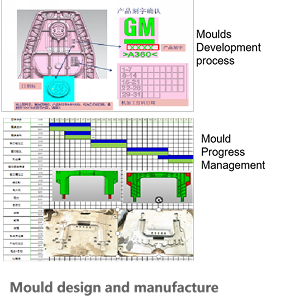

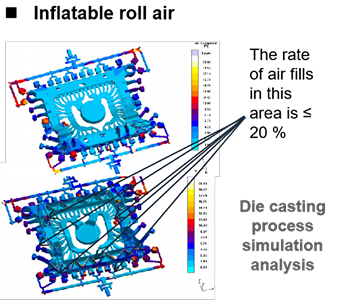

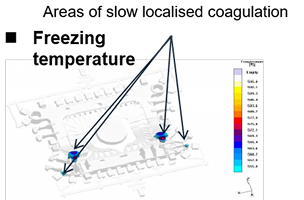

Integrating ZWSOFT/AutoCAD 2D drafting with NX advanced 3D modeling, our mold design system achieves ±0.05mm geometric accuracy for complex automotive and aerospace components. Through dual CAE verification (MAGMASOFT & FLOW-3D), we optimize filling patterns and thermal stresses at sub-millimeter scales, reducing prototyping iterations by 40%. Unified PLM workflows bridge conceptual design to CAM toolpath generation, supporting 5-axis machining and IoT-enabled production monitoring.

All-in-one Die Casting Solutions

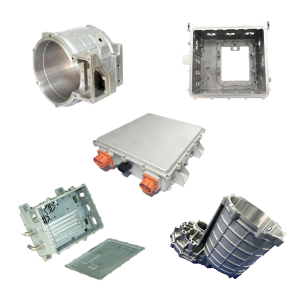

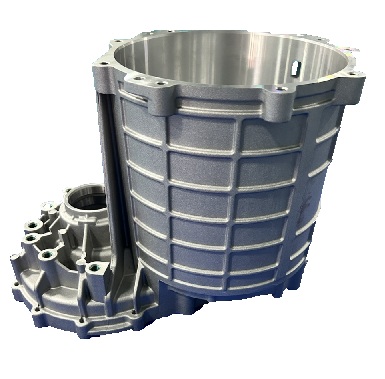

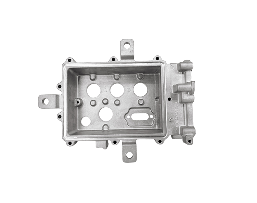

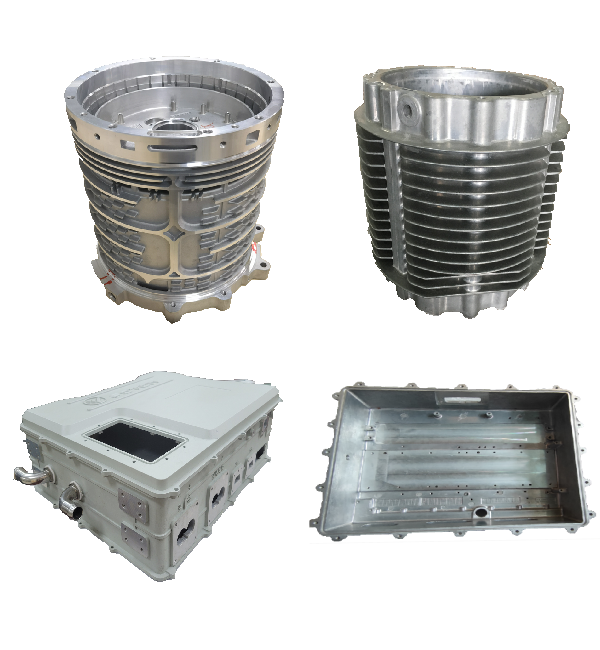

New Energy Vehicle Motor Housing & Controller

Suitable for:

New energy vehicle parts with certain air tightness requirements. Application of insert die casting (housing with bearing bush) and friction stir welding process (controller housing with water channel).

Commonly used materials:

ADC12

Motors / Electronic Controls Housing

Process: die-casting + friction stir welding + CNC precision machining + gas density test+ cleaning.

Application: Can be used in new energy vehicle motor shell, power controller shell, all-in-one power assembly.

Commonly used materials:

A360, ADC12

Vacuum Die Casting

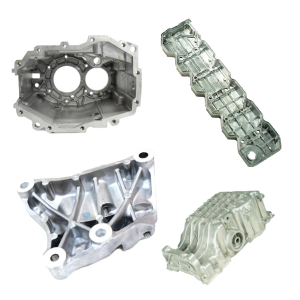

Auto Parts

Suitable for:

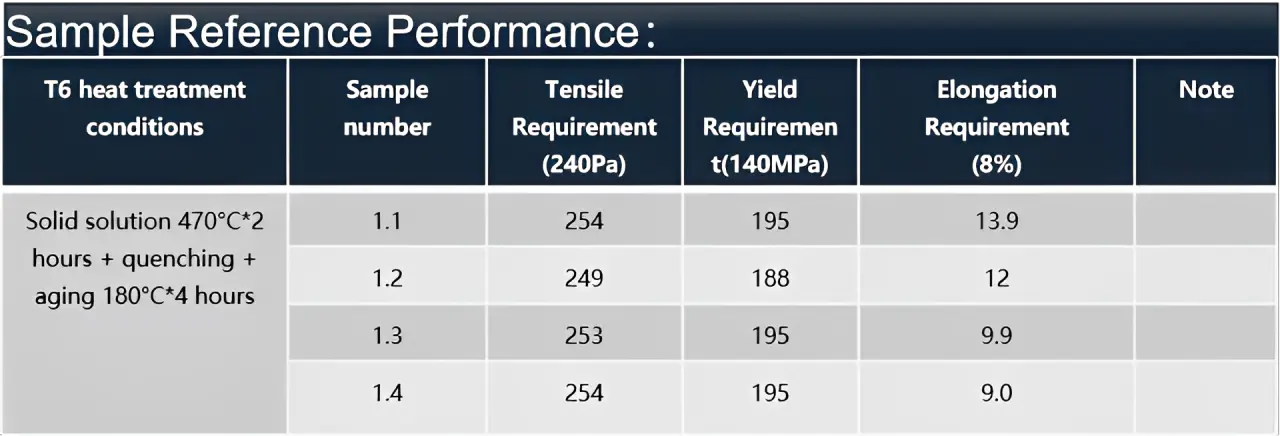

Thin-walled automotive parts with high mechanical property requirements.

Such as:

Shock absorber tower, non-hollow structure sub-frame, body structure parts, etc. Common Materials: AlSi10MnMg-T6.

FSW generates frictional heat via a high-speed rotating probe, achieving molecular-level metallurgical bonding of dissimilar materials (e.g., Al/Cu) in solid state.

Weld strength ≥90% base metal, eliminating leakage risks in EV powertrain housings.

Friction Stir Welding (FSW)

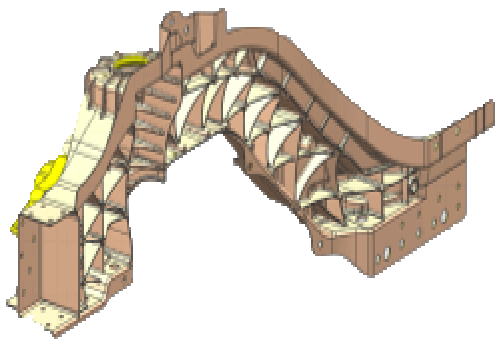

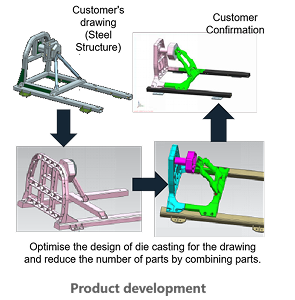

GM Electric Hummer Spare Wheel Carrier Development Case

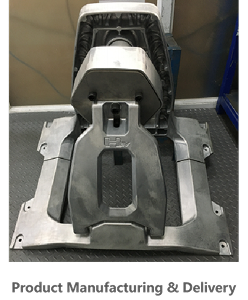

1. Customers provide drawings and corresponding materials and other parameters, EMP provides customers with feasible die casting structure design.

2. Professional mould design team, perfect project management, guarantee the production schedule, strict control of product quality.

3. Timely completion of sample delivery, small batch production and smooth entry into mass production. Closed-loop management of order quality/delivery. The project has gained the trust of customers as well as good comments.

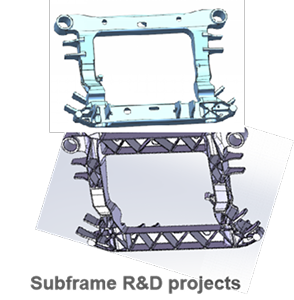

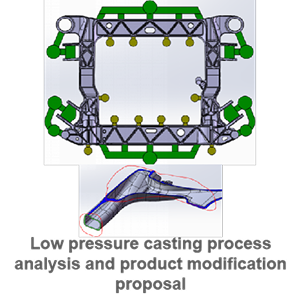

Various process analysis cases

According to the customer’s products, design and R & D projects to provide a variety of processes including low pressure casting, die casting, and simulation analysis, process plan proposal, product modification and other technical support to shorten the customer’s product design and feasibility analysis cycle.

Product Category

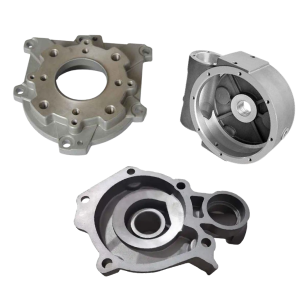

Automotive Parts

Automotive Parts Beyond Metal. Beyond Standards. Cylinder Head Cover Engine...

Learn MoreIndustrial Parts

Industrial Parts Engineering the Impossible Mission-critical castings for medical &...

Learn More