Choosing the wrong metal for your component can be a costly mistake. It leads to parts that are too heavy, too weak, or unable to withstand their operating environment, sending you back to the drawing board.

The most common metals for die casting1 are aluminum2, zinc3, and magnesium4. Aluminum dominates automotive and industrial applications for its balance of weight and strength. Zinc is for precision parts, and magnesium is for when extreme lightweighting is the primary goal.

When I begin a new project with a client, one of the first questions we have to answer is, "What material will we use?" This decision is fundamental. It affects the mold design5, the casting process6, and the final performance of the part itself. While many alloys7 exist, the vast majority of parts we produce at EMP Tech, and that you’ll see in the industry, are made from one of three metal families. Getting this choice right from the start saves an incredible amount of time and money down the line. Let’s break down the main players.

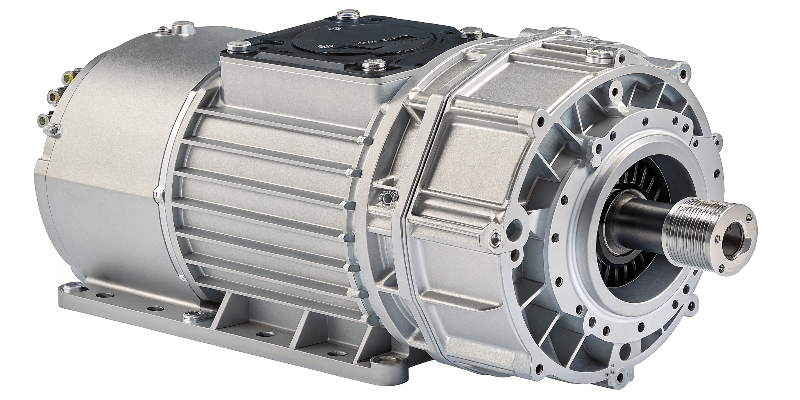

Why Is Aluminum the Go-To Metal for Lightweight Automotive Parts?

You’re under pressure to reduce vehicle weight without sacrificing strength. Steel parts are often too heavy for modern efficiency goals, but you need a material that can handle the structural and thermal loads of a powertrain.

Aluminum has the best combination of strength, low weight, corrosion resistance, and high thermal conductivity8 for the cost. This makes it the ideal choice for EV motor housings, battery enclosures, and complex structural components where performance and efficiency are critical.

There’s a reason about 80% of the die castings we produce are aluminum. In my two decades in this business, I’ve watched aluminum become the backbone of modern automotive lightweighting9. When I discuss options with a procurement director from Germany, we always come back to aluminum’s incredible balance of properties. For critical EV components like inverter housings or battery trays, it solves multiple problems at once.

First, its strength-to-weight ratio10 is excellent. We can design parts that are as strong as older steel components but at nearly half the weight, which is a massive win for EV range. Second, its thermal conductivity8 is fantastic. An EV motor or battery generates a lot of heat, and an aluminum housing acts as a giant heat sink to pull that heat away, protecting the sensitive electronics inside. Common alloys like A380 and ADC12 provide a great mix of castability and mechanical properties11, making them reliable workhorses for the demanding automotive applications my team and I work on every day.

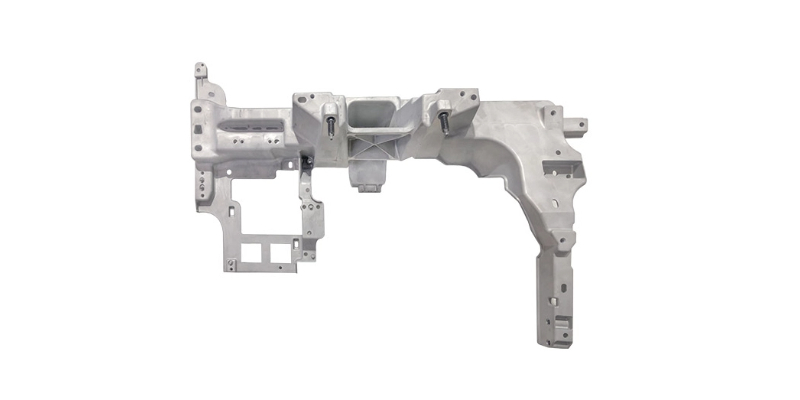

What Are the Applications and Advantages of Magnesium Die Casting?

Your project demands the absolute lightest component possible, and even aluminum isn’t light enough. This is a common challenge for high-end automotive parts or portable electronic devices where every single gram counts.

Magnesium is the lightest of all structural metals, about 33% lighter than aluminum. Its primary advantage is extreme weight reduction, making it perfect for steering wheel frames, dashboard support beams, and laptop cases where minimizing weight is the top priority.

Once in a while, a project comes along where the primary goal is to shed every possible gram. This is where magnesium comes into play. I remember working on a project for a premium European automaker where we used magnesium for the cross-car beam—the large structural part that sits behind the dashboard. Using magnesium saved them several kilograms in a high location on the vehicle, which improves its center of gravity and handling.

The main advantage is simple: it’s the lightest structural metal you can use. However, it comes with trade-offs. Magnesium alloys, like the common AZ91D, are more expensive than aluminum and require special processing. The material is more reactive, and we have to use a specific process with protective gases to prevent the molten metal from oxidizing. So, while it offers incredible weight savings, its use is typically reserved for those applications where the performance benefit justifies the higher cost and complexity. It’s a specialized solution for a specific problem.

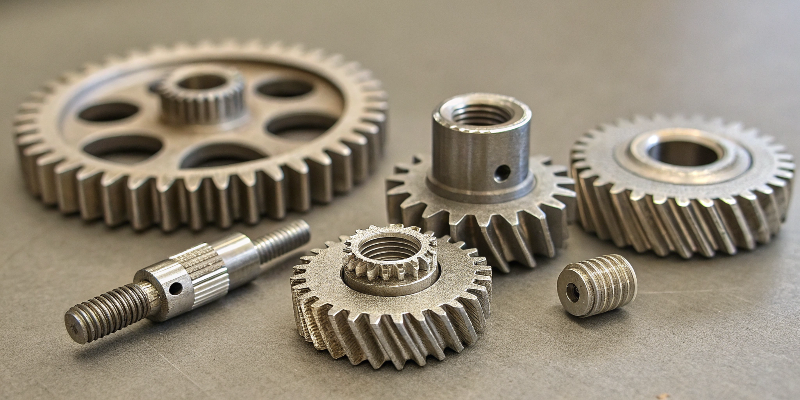

When Are Zinc Alloys Used in High-Volume Precision Casting?

You need to produce millions of small, complex parts with fine details and a beautiful surface finish. Using aluminum would require too much costly machining and polishing after casting to achieve your goals.

Zinc is the best choice for small, high-precision parts needing excellent thin-wall capability and a smooth, "Class A" surface finish directly from the mold. It is ideal for electrical connectors12, complex hardware, gears, and decorative components.

While my world is dominated by large aluminum castings for EVs, we can’t forget about zinc. It’s a hero in a different part of the manufacturing world. Zinc’s properties make it perfect for parts where intricate detail is key. A great example is the market for high-end electrical connectors or custom automotive badging.

The secret is zinc’s low melting point and excellent fluidity. It flows into the mold like water, filling every tiny feature and thin wall section with incredible fidelity. This allows us to cast net-shape parts that require almost no secondary machining. Furthermore, because it’s cast at a lower temperature, the molds last much longer—often for millions of shots. This makes the cost per part13 very low in high-volume production14. When an engineer needs a part that is both strong and has a perfect cosmetic finish straight out of the tool, zinc alloys from the ZAMAK15 family are almost always the right answer.

How Do the Mechanical Properties of These Die Casting Metals Compare?

Deciding between aluminum, magnesium, and zinc can be confusing without seeing the data side-by-side. You need a clear comparison to make an informed choice based on strength, weight, and temperature performance.

Aluminum offers the best all-around performance. Magnesium provides the lowest weight but has lower strength and temperature resistance. Zinc is very strong and precise at room temperature but is the heaviest and not suitable for high-heat applications.

To help engineers in this field make the right call, I often show them a simple comparison table. Numbers don’t lie, and this chart makes the trade-offs very clear. It shows why there’s no single "best" metal—only the best metal for a specific job.

| Property | Aluminum (A380) | Magnesium (AZ91D) | Zinc (Zamak 3) |

|---|---|---|---|

| Density (g/cm³) | ~2.7 | ~1.8 | ~6.6 |

| Tensile Strength (MPa) | ~324 | ~230 | ~283 |

| Melting Point (°C) | ~590 | ~596 | ~387 |

| Thermal Conductivity | High | Medium | High |

Looking at this, you can see why aluminum is so popular. It has good strength at a very low density. Magnesium is the clear winner on weight, but you take a hit on strength. Zinc is surprisingly strong, but it’s over twice as heavy as aluminum, ruling it out for most lightweight applications. Also, its low melting point means it can’t be used in components that get hot, like powertrain housings. This data is the starting point for every material selection discussion we have.

Conclusion

The metal you choose defines your part’s potential. Aluminum offers a balanced solution for most needs, while magnesium and zinc provide specialized performance for extreme lightweighting or high-precision applications, respectively.

-

Get a comprehensive overview of the die casting process and its applications in manufacturing. ↩

-

Explore the advantages of aluminum in die casting, including its strength, weight, and thermal properties. ↩

-

Learn why zinc is favored for high-precision parts and its unique properties that enhance casting quality. ↩

-

Discover how magnesium’s lightweight properties make it ideal for specific applications in die casting. ↩

-

Discover the critical role of mold design in ensuring high-quality die cast components. ↩

-

Understand the key factors that affect the die casting process and the quality of the final product. ↩

-

Learn about the various alloys used in die casting and their specific applications. ↩

-

Find out how thermal conductivity impacts the performance of die cast components. ↩ ↩

-

Explore the concept of automotive lightweighting and its benefits for vehicle efficiency. ↩

-

Understand the significance of strength-to-weight ratio in material selection for die casting. ↩

-

Get insights into the mechanical properties of different metals used in die casting. ↩

-

Learn about the role of die casting in producing high-quality electrical connectors. ↩

-

Explore how die casting can lower the cost per part in high-volume production. ↩

-

Learn about the advantages of high-volume production and its impact on cost efficiency. ↩

-

Explore the properties and uses of ZAMAK alloys in precision die casting. ↩