Your EV design requires large, leak-proof aluminum structures, but traditional welding creates weak points. These potential failures in battery trays and chassis components are a risk you cannot afford.

Friction Stir Welding (FSW) joins die-cast aluminum1 parts without melting them, creating a solid-state bond2. This produces strong, leak-proof, and lightweight assemblies, which are essential for critical EV components like battery enclosures, motor housings, and structural parts3.

In my 20-plus years in die casting, I’ve seen technologies come and go. But FSW is different. It’s a game-changer for electric vehicle manufacturing. We often have customers who need to produce a huge battery enclosure. Casting a part that large in one piece is incredibly difficult and full of risk. The alternative, welding smaller cast sections together, used to mean compromising the strength and integrity of the assembly. FSW changes that equation completely. It allows us to leverage the precision of die casting for smaller, manageable parts and then join them into a large, flawless structure. Understanding how this technology works is the first step to unlocking its potential for your projects.

How does Friction Stir Welding really work?

When you hear "welding," you might think of intense heat, sparks, and brittle joints. This perception can prevent you from considering a far superior joining technology for critical aluminum components.

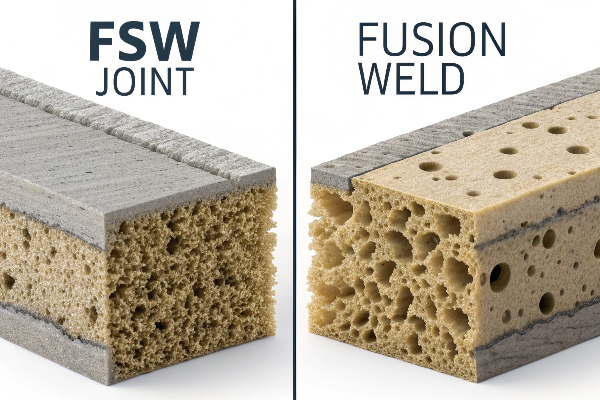

FSW uses a rotating, non-consumable tool that plasticizes and stirs the metal from two separate pieces together. This solid-state process avoids melting the aluminum, preventing common defects like porosity and cracking and creating a stronger, more uniform joint.

Definition and Process

Let me break down what happens. Imagine a specialized tool with two main parts: a rotating pin and a wider shoulder. This tool is lowered onto the joint line between two aluminum parts that are securely clamped together. As the tool spins, the friction from the pin and shoulder generates heat. Crucially, this heat softens the aluminum into a plastic-like state but never melts it. The rotating pin then travels along the joint, literally stirring the two pieces of plasticized metal into one. The shoulder forges the top surface, creating a smooth, high-quality finish. No filler wire, no shielding gas, and no fumes are involved. It’s more like a localized forging process than a traditional weld.

Relevance to Electric Vehicles

So why is this a perfect match for EVs? Electric vehicles are built around a large battery pack, which needs a robust, perfectly sealed enclosure. Die casting is the ideal process for making the complex shapes required for these trays, but casting them as a single piece over a meter long is often impractical. With FSW, we can die-cast smaller, high-integrity sections and then join them. The resulting FSW seam is as strong as the original casting and is completely leak-proof, meeting strict IP674 or higher requirements for battery protection.

What are the real advantages of using FSW on die-cast parts?

Welded joints are often seen as the weakest link in any design. A single failed joint can compromise the safety and performance of an entire EV battery pack, a risk no OEM can accept.

FSW delivers superior joint strength because it avoids the pitfalls of melting metal. It creates a defect-free, highly repeatable weld that is essential for producing the durable and lightweight EV components that your projects demand.

Enhanced Strength and Durability

In traditional welding (like MIG or TIG), the aluminum is melted and re-solidified. This process can introduce defects like porosity and create a brittle, coarse-grained structure at the joint. The result is a weak point. I remember reviewing test data for a customer’s battery tray prototype. The tensile strength5 across the FSW joint was over 95% that of the parent die-cast material. A conventional weld would struggle to achieve 60% and have much less consistent results. FSW is a solid-state process, so it actually refines the grain structure6 of the aluminum in the stir zone, leading to exceptional mechanical strength and fatigue resistance.

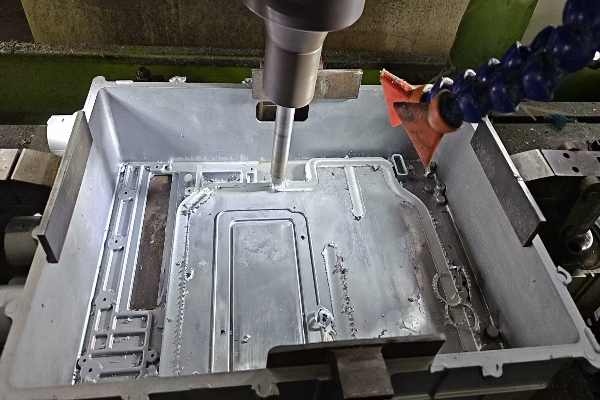

Improved Precision and Quality

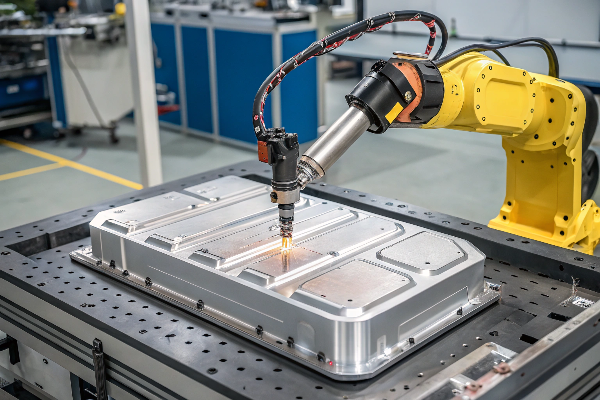

Because FSW uses low heat input, there is minimal distortion. This is a massive advantage for large, flat components like battery trays that must remain dimensionally stable to ensure proper sealing and assembly. The entire process is automated by a robot or CNC gantry, meaning it is perfectly repeatable. The speed, force, and rotation are precisely controlled, ensuring the first joint and the thousandth joint have the exact same properties. For a quality engineer, this level of process control is invaluable.

Lightweight Design Benefits

The high strength of FSW joints allows engineers to design parts more efficiently. You no longer need to add thick flanges or extra material just to compensate for a weak welded connection. This allows for thinner walls and more optimized designs, directly supporting the critical lightweighting goals of every electric vehicle program.

Where is FSW being applied in EV manufacturing?

You need to assemble large, complex aluminum components for your EV project. Using traditional fasteners adds weight, while fusion welding introduces unacceptable weak points. You need a better solution for critical assemblies.

FSW is primarily used for assembling large battery enclosures7 where its leak-proof and high-strength joints are vital. It is also used for motor housings8, chassis sub-assemblies, and cooling plates9, enabling the use of multiple optimized castings to create a single, superior component.

Battery Housings

This is the number one application for FSW in the EV world. Battery enclosures need to be large, structurally sound, and perfectly sealed from water and dust. By die-casting multiple smaller sections and joining them with FSW, we can produce a final assembly with higher quality and tighter tolerances than would be possible with a single massive casting.

Motor and Transmission Components

Some advanced motor designs require housings with complex internal cooling channels. Often, the best way to produce these is to cast the housing in two halves and then permanently join them. FSW provides a strong, hermetic seal that becomes an integral part of the housing itself.

Chassis and Structural Parts

FSW allows for the creation of innovative hybrid structures10. For example, a complex die-cast shock tower can be joined to a simple aluminum extrusion to form a subframe. This approach lets designers use the best manufacturing process for each part of the assembly, optimizing for both strength and cost.

| EV Application | Key Benefit of FSW |

|---|---|

| Battery Enclosure / Tray | Leak-proof seal (IP67+), high strength, dimensional stability11 |

| Motor Housing | Hermetic sealing, high structural integrity |

| Chassis Components | High-strength joints, enables hybrid material structures |

| Cooling Plates / Cold Plates | Creates leak-proof internal channels for liquid cooling |

Why choose EMP Tech for FSW in EV aluminum die casting?

You’re worried about finding a supplier with proven expertise in both die casting and advanced FSW. Trying to coordinate separate vendors for these critical processes adds risk, cost, and complexity to your project.

At EMP Tech, we integrate advanced robotic FSW technology12 directly into our die casting and machining production lines. Our IATF 16949 certification13 covers the entire process, offering you a single, reliable, and accountable source for your most critical EV components.

Advanced Equipment and Expertise

We don’t just offer FSW as a separate service; it is a core part of our integrated manufacturing solution. A part can come from one of our die casting machines, move to our in-house CNC centers for precision interface machining, and then proceed directly to a robotic FSW cell for assembly. Our engineers are experts in both casting design and the physics of FSW, ensuring that the entire process is optimized from the very beginning. This seamless flow under one roof eliminates the logistical and quality risks associated with a fragmented supply chain.

IATF 16949 Certified Quality

For our automotive customers, this is non-negotiable. Our entire operation, from raw material intake to the final welded assembly, is managed under our IATF 16949 certified quality system. This means that every step, including the FSW parameters, is controlled, monitored, and documented. You get full traceability and the assurance that your parts are produced to the highest automotive standards.

Tailored Solutions for EV Manufacturers

We have hands-on experience producing complex die-cast and FSW assemblies for electric vehicle14 projects. We understand your specific challenges, whether it’s achieving IP67 sealing, managing thermal interfaces for battery cooling, or meeting aggressive lightweighting targets. We partner with you from the DFM stage to deliver a complete, validated, and ready-to-assemble solution.

Conclusion

Friction Stir Welding15 is a vital technology for modern EV manufacturing. Partnering with an integrated supplier like EMP Tech de-risks its adoption, ensuring you receive strong, lightweight, and reliable components.

-

Learn about die-cast aluminum’s properties and its role in producing lightweight, durable components. ↩

-

Discover the significance of solid-state bonding in enhancing the strength of welded joints. ↩

-

Learn about the role of structural components in ensuring the safety and integrity of EVs. ↩

-

Gain insights into the IP67 rating and its importance for protecting electronic components. ↩

-

Understand how tensile strength is evaluated and its relevance in material selection for EVs. ↩

-

Explore how grain structure affects the mechanical properties of metals, especially in welding. ↩

-

Understand the importance of robust battery enclosures for safety and performance in EVs. ↩

-

Explore the complexities of motor housing design and how FSW addresses these challenges. ↩

-

Discover how cooling plates are essential for managing thermal conditions in EVs. ↩

-

Explore the advantages of hybrid structures in optimizing material use and performance. ↩

-

Learn about the importance of maintaining dimensional stability in large components. ↩

-

Discover the advantages of automation in Friction Stir Welding for precision and efficiency. ↩

-

Understand the significance of IATF 16949 certification in ensuring quality in automotive manufacturing. ↩

-

Explore the growing importance of electric vehicle in sustainable transportation. ↩

-

Explore the mechanics of FSW to understand its advantages in creating strong, leak-proof aluminum structures. ↩