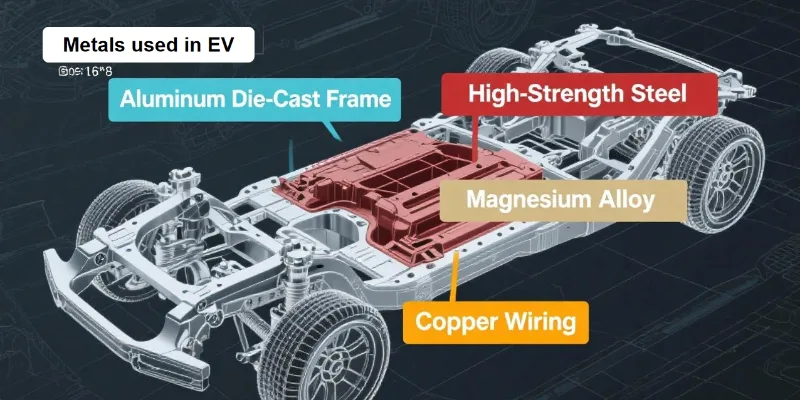

Electric car parts must be light but strong. Are you wondering what metal makes this possible? Ignoring this answer could leave you behind in EV tech.

Aluminum is the most used metal in electric cars. Its lightweight nature helps increase range and efficiency. It is used for chassis, battery housings, and motor casings. Other key metals include steel, copper, and rare earths, each playing a vital role.

The move to electric cars changed how we think about car parts. As an engineer deeply involved in aluminum die casting, I have seen this shift first-hand. It is not just about making parts, but making them lighter and stronger. My team and I work every day to find the best solutions for our customers’ complex needs. Let us look at why certain metals are picked and how they change car design, performance, and safety.

Why is aluminum the most widely used metal in electric vehicles?

You need lighter, more efficient EV parts. But what material truly delivers on both? Not knowing this key metal means missing out on top performance and range.

Aluminum is most used because it is lightweight, strong, and resists rust. Its low density helps extend EV range and improve energy efficiency. It is key for battery cases and structural parts.

I have spent over two decades working with aluminum alloys, especially in die casting. I have seen how cars use more and more aluminum. For electric vehicles, weight is a very big deal. Every kilogram saved means more miles on one charge. This is how we fight "range anxiety." Aluminum1 helps with this. It is about one-third the weight of steel2 but still very strong. It also resists rust. This is good for battery housings3 that need a long life. My team often works on motor controller housings4 and casting structural parts for EVs. These parts need to be very precise and lightweight5. For example, a customer from Canada needed a very light, strong housing for a new motor controller. We chose a high-strength aluminum alloy6. We optimized the design using simulation. This meant less material used. It shaved off important weight. This directly helped their EV’s range and performance.

The Lightweight Advantage

Aluminum also helps manage heat in EV parts. It takes heat away well. This is good for parts like motor casings7, where heat can cause problems. It keeps parts cool. Its ability to be recycled is also a big plus for sustainability8. This lessens its effect on the environment.

How does steel compare to aluminum in EV manufacturing?

Trying to pick the best material for an EV frame? Without knowing how steel stacks up, you might miss key strengths or weaknesses for your design and budget.

Steel is used in EVs where maximum strength or low cost is needed. It is heavier than aluminum, which hurts range. But for crash safety structures, it is often the preferred choice.

When working on a new EV project, engineers always face a choice: aluminum or steel? Steel has long been the backbone of car building. It is strong, easy to work with, and cheap. When I was a frontline worker on the factory floor, steel was in almost everything. But for EVs, the rules changed. Weight became the main enemy. Steel is still used where high strength is needed for safety. For example, in parts that protect people in a crash, like door beams. It is also found in some frame parts and suspension. It is cheaper to make than aluminum. This helps lower the overall cost of the car. However, steel weighs much more than aluminum. If you use too much steel, the car gets heavier. This means it uses more power. It drives fewer miles on one charge.

Choosing the Right Material for the Job

This is where aluminum wins out. For a battery enclosure, aluminum is almost always the choice. It is lighter and helps conduct heat away from the batteries. Using steel would make the battery pack too heavy. It would also be harder to cool. So, designers must pick where each metal makes the most sense. They balance weight, strength, cost, and safety.

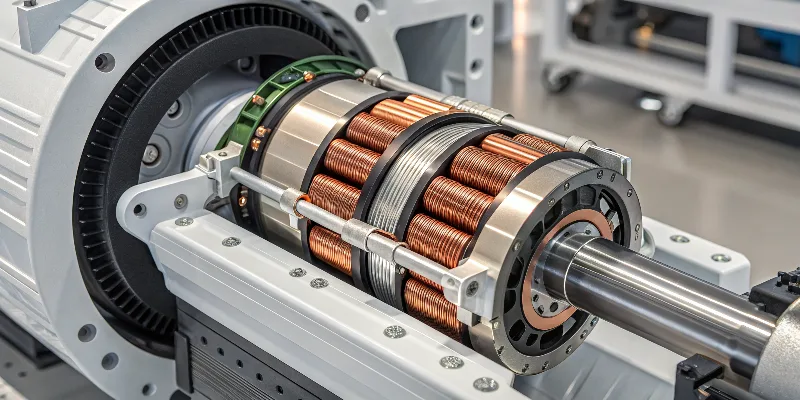

What role does copper play in EV batteries and motors?

Are you overlooking a key material for EV power? Without enough copper9, your car motors and batteries cannot work at their best, impacting efficiency and performance.

Copper is vital for EV power because it is excellent at carrying electricity. It is used in battery wiring, motor windings, and busbars. It makes sure power flows well and motors work with high efficiency.

While aluminum builds the body, copper makes the EV move. In my work with motor controller housings, I see how crucial copper is. It is the blood of the electric power system. It moves energy from the battery to the motor. It is also key inside the motor. No other metal carries electricity as well as copper for a reasonable cost. My team often works on housings that need to protect copper parts. The customer needs good heat removal. Copper gets hot when electricity flows through it. Our aluminum housings help to pull that heat away. I once worked on a project where the copper busbars in a motor controller were getting too hot. This was causing problems. We found a better way to join the copper parts. We also improved the cooling design of the aluminum housing. This kept the copper cool. It let the system work at its best.

The Electrical Backbone

Copper is also found in charging cables. It is in the main wires throughout the car. It is heavy, but its ability to carry huge amounts of power makes it a must-have. Without copper, EVs simply could not work.

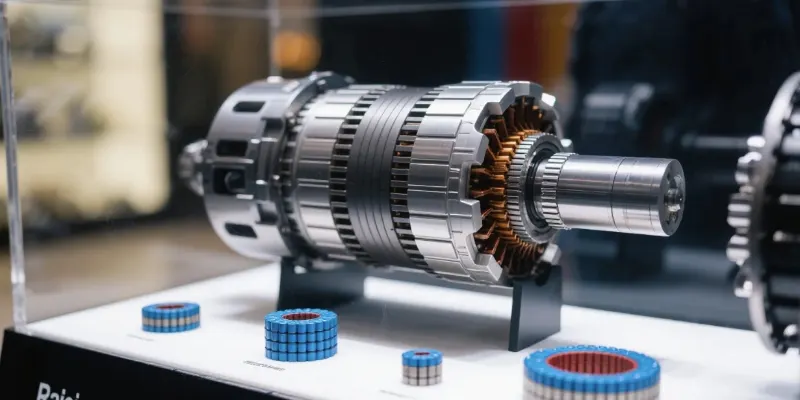

How are rare earth metals used in electric vehicle components?

Are you puzzled by talk of "rare earth" metals in EVs? Not understanding their role means missing why today’s powerful EV motors are so small and efficient.

Rare earth metals, like neodymium, create the powerful, lightweight magnets used in most EV motors. These magnets make motors smaller and more efficient, which is crucial for maximizing an EV’s power and driving range.

Rare earth metals are not as common as aluminum or steel. But they are tiny powerhouses. When I first worked on EV components, I wondered why some motors were so small yet so strong. The answer lies in these special metals. They are not rare in the earth itself. But they are hard to mine and process. My focus is on the die-cast housings that hold these motors. These housings must be made with very high precision to work with these strong magnets. Rare earth metals like Neodymium are used to make very strong permanent magnets. These magnets are the heart of many EV motors. They make the motor spin. Because the magnets are so strong, the motor can be smaller and lighter. This saves space and weight in the car. It also makes the motor more efficient.

Powering Efficiency

This means the motor uses less battery power, helping the car go further. Another rare earth metal, Dysprosium, is sometimes added to these magnets. It helps them stay strong at high temperatures. This is important because EV motors get hot. The global supply of these metals can be tricky. This means car makers must plan carefully. They must make sure they can get enough of them. Without these rare earth magnets, many current EV designs would need to be much bigger or use more energy.

Why is magnesium gaining attention for lightweight EV structures?

Are you seeking even lighter EV parts than aluminum offers? If so, you need to know about magnesium10. Ignoring it means missing the next level of weight savings11.

Magnesium is gaining interest for EVs because it is even lighter than aluminum. It is strong for its weight. This helps make car parts much lighter than before. It is used for special parts like interior frames and gear cases.

For years, aluminum was the king of lightweighting. But engineers always look for what is next. Magnesium is now getting more attention. It is even lighter than aluminum. As a die-casting expert, I track these trends closely. While aluminum is my main focus, I understand the possible benefits of magnesium. It is about one-third lighter than aluminum. This is a big deal when trying to shave off every possible gram. Magnesium has been used in cars for some time, like for steering wheel frames or dashboard supports. But for EVs, new uses are coming. It could be used for parts of the battery housing or subframes. It is a bit trickier to work with than aluminum. It reacts more easily during casting. But new ways of casting are making it easier. My team has looked at magnesium for special uses.

The Ultra-Light Future

For example, on a project for an internal frame for an electronic part. Here, every bit of weight saved counts. Magnesium also helps absorb energy in a crash. This can be good for safety. As EV makers push for longer range and better performance, magnesium will likely play a bigger role. It offers extreme lightweighting. This helps overall car efficiency.

How do material choices influence EV cost, safety, and efficiency?

Are you unsure how material choices affect EV performance? Picking the wrong metal can raise costs, lower safety, or reduce how far the car can go.

Material choices in EVs directly affect cost, safety, and efficiency. Lighter materials like aluminum boost range. Stronger materials like specialized steel improve safety. Cost is balanced by material price and manufacturability for each part.

At EMP Tech, working with Tier 1 suppliers12 from Germany and the US, we see how every material choice matters. It is a complex puzzle. What is cheapest might not be safest. What is lightest might be too fragile. My experience helping customers solve design and manufacturing issues taught me this. It is never just about one factor. When we help design a motor controller housing, for example, we consider many things. Cost is always on the table. Aluminum die casting can be very cost-effective for high volumes. But the raw aluminum itself costs more than steel. Safety is key. Parts must protect batteries and electronics in a crash. They must also keep people safe. Aluminum can absorb crash energy well when designed right. Lastly, efficiency. A lighter car uses less energy and goes further. This is the biggest driver for aluminum use.

Factors in Material Selection:

| Factor | Aluminum (Die Casting) | Steel (Stamping/Forming) |

|---|---|---|

| Weight | Very Light | Heavy |

| Cost | Medium (High Volume) | Low |

| Strength | Good (High Strength Alloys) | Excellent |

| Primary Use | Structural, Housings, Frame | Chassis, Safety Structures |

We always aim for an optimal mix. We use lightweight materials effectively. This helps reach overall goals.

Conclusion

Aluminum is the most used metal in electric cars due to its lightweight advantage. But other metals like steel, copper, and rare earths also play vital, specific roles.

-

Explore how aluminum’s lightweight and strength make it essential for electric vehicles. ↩

-

Find out why steel is still relevant in EVs despite aluminum’s advantages. ↩

-

Learn about the importance of materials in ensuring battery safety and efficiency. ↩

-

Explore the significance of material choices in motor controller design. ↩

-

Discover how lightweight materials enhance EV performance and efficiency. ↩

-

Discover the benefits of high-strength aluminum alloys in electric vehicle design. ↩

-

Understand the role of motor casings in EV efficiency and heat management. ↩

-

Learn how material selection can contribute to the sustainability of EVs. ↩

-

Explore copper’s critical function in EV power systems and efficiency. ↩

-

Explore magnesium’s potential for lightweighting in future EV designs. ↩

-

Discover the relationship between weight savings and EV performance. ↩

-

Learn about the importance of Tier 1 suppliers in the EV manufacturing process. ↩