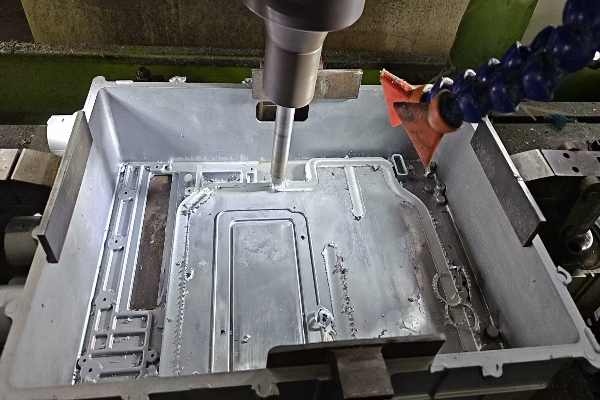

How can you optimize Gearbox Housing Die Casting from Mold Design to Final Process?

Are your gearbox housing projects plagued by defects and delays? An unoptimized process drains resources and threatens deadlines, causing major headaches for your entire team. To optimize gearbox housing die casting, you must focus on four key areas. Start with a robust mold design, select the right aluminum alloy, fine-tune critical process parameters, and implement […]