Are your EV projects struggling to meet targets for range, cost, and safety? Traditional materials and manufacturing methods often add weight and complexity, directly hindering performance and profitability.

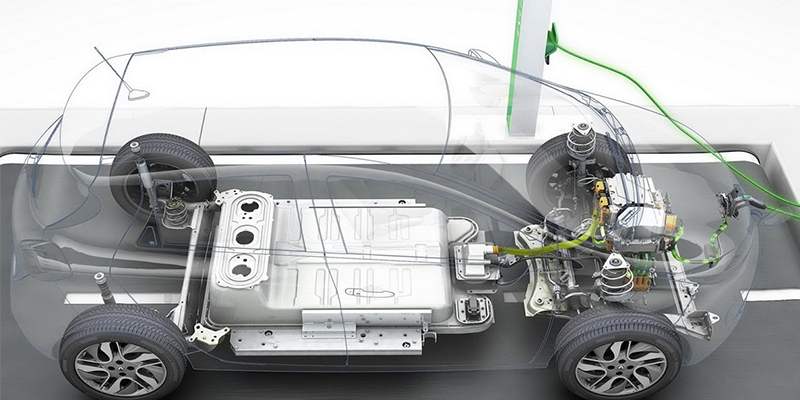

High-pressure die-cast aluminum is revolutionizing EVs by enabling the production of lightweight, strong, and intricate components at scale. This improves vehicle efficiency, enhances structural integrity, and simplifies the manufacturing process, making it a cornerstone technology for modern e-mobility.

Working in this industry for over two decades, I’ve had a front-row seat to the EV revolution. The challenges our customers—Tier 1 suppliers from Germany, the US, and Canada—bring to us have changed dramatically. It’s no longer just about making a single part. It’s about how that part contributes to the entire vehicle system. The conversations always come back to a few key things: reducing weight to extend battery range, managing heat from powerful electronics, and simplifying assembly on a massive scale. High-pressure die casting is the technology my team and I use to solve these exact problems, turning complex engineering challenges into tangible, high-performance parts1.

What is high-pressure die-cast aluminum in electric vehicles?

Does "high-pressure die-casting" sound like just another piece of industry jargon? Not understanding this core process can make it difficult to appreciate why it is so critical for EV production.

High-pressure die-casting, or HPDC, is a manufacturing process that forces molten aluminum alloy into a hardened steel mold (a die) under extreme pressure. This method produces highly precise, complex, and thin-walled components that are ideal for electric vehicles.

When I first started on the workshop floor, I learned quickly that die casting is all about speed and pressure. The molten metal is injected into the mold cavity in just milliseconds. This rapid filling and solidification process is what gives die-cast parts their fine-grained microstructure and excellent surface finish, often requiring minimal secondary machining. For EVs, where hundreds of thousands of identical, high-quality parts are needed, this efficiency is a game-changer. Unlike slower methods like sand casting, HPDC allows us to create parts with intricate features, such as cooling channels2 and mounting bosses, directly into the component. This integration eliminates the need for multiple smaller parts and the associated assembly steps, saving both time and money for our clients.

Which key aluminum die-cast parts boost EV performance?

Are you wondering where exactly aluminum die-casting makes the biggest impact? An EV’s performance is not just about its motor; it is highly dependent on the components that house and protect it.

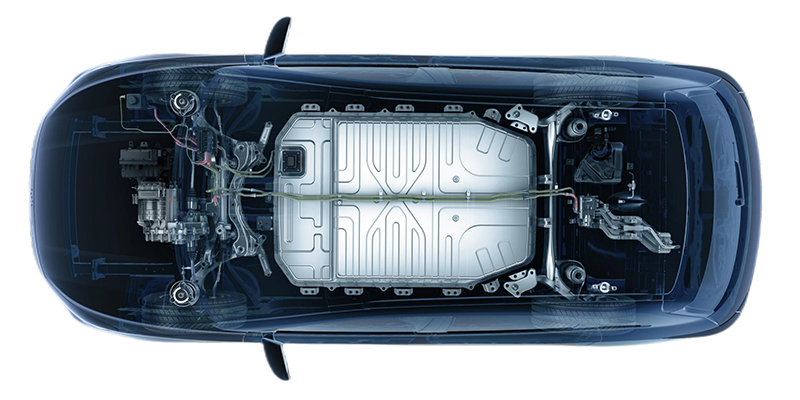

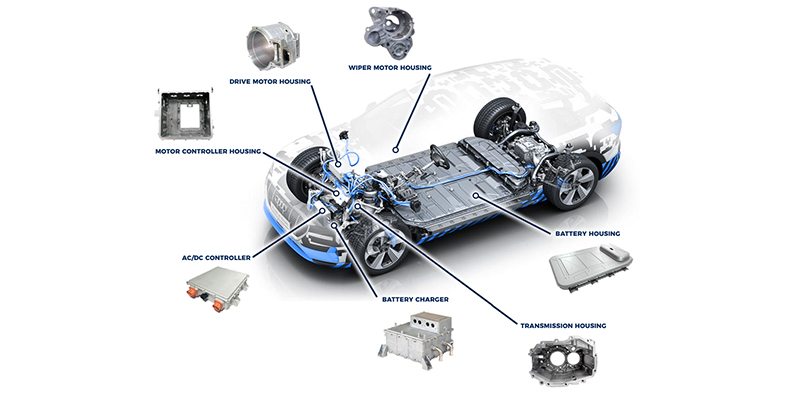

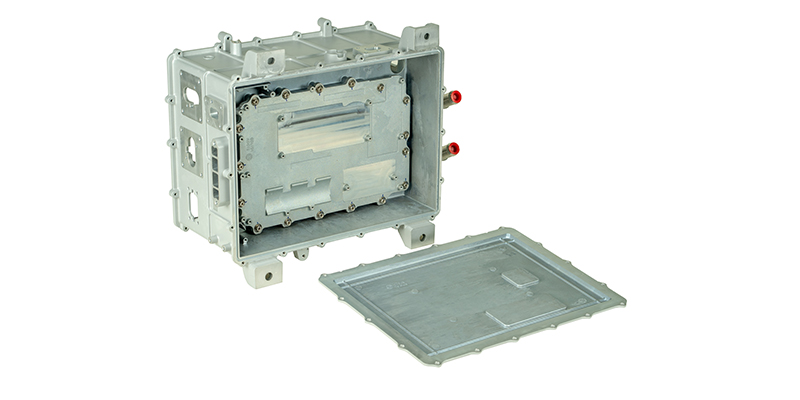

The most critical parts are battery enclosures, motor housings, and inverter casings. These components directly influence an EV’s range, power, and safety by reducing weight while providing strength and thermal management.

My team has led the development of each of these core components. For a recent project, we designed a large battery enclosure. It had to be incredibly strong to protect the cells in a crash, but also lightweight3 to maximize the vehicle’s range. Using HPDC, we integrated cooling channels directly into the floor of the enclosure. For a motor housing, precision is everything. The bearings for the motor’s rotor must be perfectly aligned, a tolerance we can easily hold with die casting. Inverter housings are another great example. They protect sensitive power electronics, so they need to be sealed perfectly and often require features for EMI shielding. In all these cases, die casting allows us to create a single, complex part that performs multiple functions, which is the key to an efficient EV design.

Critical Die-Cast EV Components

| Component | Primary Function | HPDC Advantage |

|---|---|---|

| Battery Enclosure | Protects battery cells, manages heat | Lightweight strength, integrated cooling channels |

| Motor Housing | Aligns motor components, dissipates heat | High precision, excellent thermal conductivity |

| Inverter/OBC Housing | Protects electronics, provides sealing | Complex geometry, EMI shielding, pressure tightness |

| Structural Nodes | Connects chassis components | Part consolidation, high rigidity, weight savings |

How does aluminum die-casting improve a vehicle’s durability?

Are you concerned about the long-term reliability and safety of lightweight vehicles? It’s a valid worry, but the right manufacturing process4 can deliver both weight savings and exceptional strength.

Aluminum die-casting improves durability by creating single-piece components with a high strength-to-weight ratio. This eliminates welds and fasteners—common failure points—resulting in a stiffer, more robust structure that offers superior corrosion resistance and crash performance.

I remember working with a procurement director from a German Tier 1 supplier who was skeptical about replacing a welded steel assembly with a single aluminum casting. The original part was made of over a dozen stamped pieces. Our proposal was a one-piece die-cast shock tower. We ran countless simulations to prove its strength. The final cast part was not only 40% lighter but also much stiffer because it had no joints or seams. This rigidity improves the car’s handling and response. Furthermore, aluminum naturally forms a protective oxide layer, which prevents rust—a huge problem with steel components. By creating strong, lightweight, and corrosion-resistant parts, die casting is fundamental to building EVs that are not just efficient, but also safe and durable for the long haul.

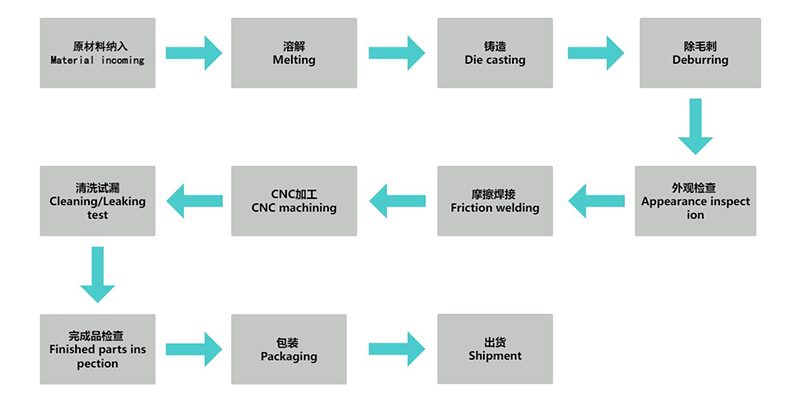

What does the high-pressure die-casting manufacturing process involve?

Is the journey from raw metal to a finished EV part a mystery to you? Understanding the factory-floor process is key to designing better components and having more productive conversations with suppliers.

The process begins by melting aluminum ingots and injecting the liquid metal into a steel die under immense pressure. The metal solidifies in seconds, the die opens, and the part is ejected. Post-processing steps like trimming and CNC machining finalize the component.

Having spent years adjusting these massive die-casting machine5s, I can tell you it is a science of precision control. Everything has to be perfect. The temperature of the molten aluminum, the speed of the injection plunger, and the cooling rate of the die are all monitored in real time.

Here is a simplified breakdown of the key steps:

- Die Preparation: The two halves of the steel mold are cleaned and sprayed with a lubricant to help with part release.

- Injection: The die is closed, and a high-pressure shot system injects the molten aluminum, filling the cavity completely.

- Solidification: Water or oil circulates through channels in the die to cool the part rapidly and uniformly.

- Ejection: The die opens, and ejector pins push the finished casting out.

- Extraction & Quenching: A robot removes the hot casting and often places it in a water bath to control its properties.

- Trimming & Finishing: Excess material, or "flash," is trimmed off, and critical features are machined to final tolerances.

This whole cycle can take as little as 60 seconds for a complex part.

Why is aluminum considered the future for EV components?

Are you deciding on a material strategy for your next EV platform? The choice you make will directly impact your vehicle’s performance, sustainability credentials, and overall cost competitiveness.

Aluminum is the future for EVs because it uniquely offers the three things this industry demands: lightweight performance for better range, high thermal conductivity for managing heat, and infinite recyclability, which is essential for sustainable manufacturing.

The push for aluminum isn’t just a trend; it’s a fundamental requirement. First, every kilogram of weight you save directly translates to more range from the battery, which is the number one concern for consumers. Second, batteries and high-power electronics generate a ton of heat. Aluminum is excellent at pulling that heat away, which is critical for performance and safety. But the point that gets many of my clients excited is sustainability6. Producing recycled aluminum uses about 95% less energy than making it from raw ore. As the auto industry moves toward a circular economy, the ability to recycle and reuse materials without losing quality makes aluminum the obvious long-term choice. It helps build a "green" vehicle with a genuinely green manufacturing footprint.

What are the common applications of die-cast aluminum in modern EVs?

Do you want to know where die-cast aluminum is being used right now? Seeing the wide range of current applications demonstrates just how versatile and indispensable this technology has become.

Beyond the well-known motor and battery housings, die-cast aluminum is used everywhere. This includes large structural body parts like underbody castings, chassis components like subframes, and sophisticated thermal management systems like cooling plates.

The applications are expanding every year. What started with smaller powertrain components has now grown into some of the largest and most complex castings ever made. The trend of "gigacasting7," where a single large die-casting replaces 70 or more stamped and welded parts, is a perfect example. We’re seeing this used for front and rear underbody sections. It massively simplifies the body shop and creates a lighter, stiffer vehicle structure. My team also works on many other applications, from the housings for ADAS (Advanced Driver-Assistance Systems) sensors to intricate cooling plates that sit between battery modules. Anywhere in an EV that you need a complex, lightweight, and strong part produced at a high volume, you will likely find high-pressure die-cast aluminum.

Conclusion

High-pressure die-cast aluminum8 is fundamental to the EV industry. It delivers the lightweight strength, thermal performance, and manufacturing efficiency needed to build the next generation of electric vehicles.

-

Explore the characteristics that make parts suitable for high-performance EVs. ↩

-

Find out how integrated cooling solutions enhance battery efficiency. ↩

-

Learn how reducing weight can significantly improve EV range and efficiency. ↩

-

Discover the steps involved in creating high-quality die-cast components. ↩

-

Get insights into the technology behind efficient die-casting processes. ↩

-

Learn about the environmental benefits of using aluminum in EVs. ↩

-

Explore the advantages of using large die-cast parts in EV manufacturing. ↩

-

Explore how this technology enhances EV performance and efficiency. ↩