Struggling with heavy, multi-part assemblies? Traditional methods are slow and add unnecessary weight. Die casting creates strong, lightweight1, single-piece components with incredible precision and speed.

In the automotive industry2, die casting3 is a core manufacturing process that injects molten metal, usually aluminum4, into a reusable steel mold under high pressure5. It is used to mass-produce complex, lightweight, and dimensionally stable parts like engine blocks6, transmission housings, and structural components7.

This process is the backbone of modern vehicle production. It allows us to create parts that are both strong and light, which is exactly what today’s cars need. From my two decades in this field, I’ve seen die casting evolve from making simple brackets to producing the massive, intricate chassis components for the latest electric vehicles. Let’s explore what this technology means for the auto industry today.

What Does Die Casting Mean in the Context of Automotive Manufacturing?

Heard the term "die casting" but unsure what it really involves? It sounds technical, but the core idea is simple and powerful. Let’s break down exactly what it means.

For automotive manufacturing, die casting means creating a finished metal part with high precision in a single step. It involves injecting liquid metal into a steel mold (a "die") to produce complex shapes8 that would otherwise require multiple manufacturing steps.

At its heart, the process is straightforward but requires immense engineering control. I remember the first time I stood next to a large die casting machine. The power and speed were incredible. In just a couple of minutes, a shot of glowing molten aluminum was transformed into a complex transmission housing.

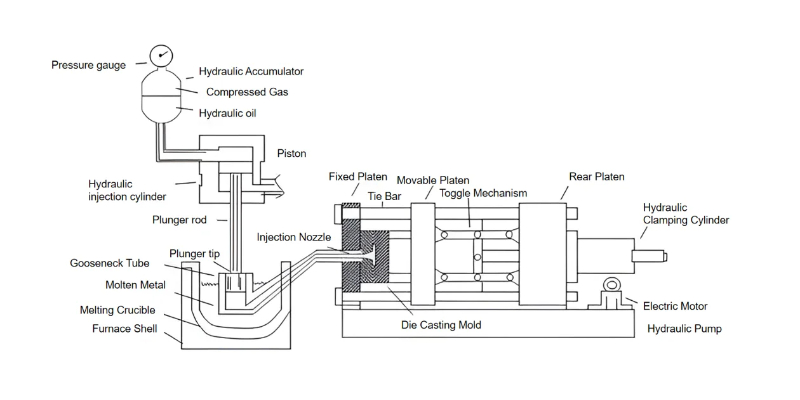

The basic steps are:

- Mold Preparation: The two halves of the hardened steel die are cleaned and lubricated.

- Injection: The die is closed, and molten aluminum is injected into the mold cavity under extreme pressure. This pressure ensures the metal fills every tiny detail of the mold.

- Cooling: The molten metal cools and solidifies rapidly within the mold.

- Ejection: The die opens, and the solid part, or "casting," is ejected.

- Trimming: Excess material, called flash and runners, is trimmed off the part.

This cycle repeats very quickly, allowing us to produce thousands of identical parts per day. This makes it perfect for the high-volume needs of the automotive world.

How Has Die Casting Evolved in the Automotive Industry Over Time?

Thinking die casting is an old, unchanging technology? It has been around for a while, but it has transformed dramatically. The parts we make today were unimaginable just a decade ago.

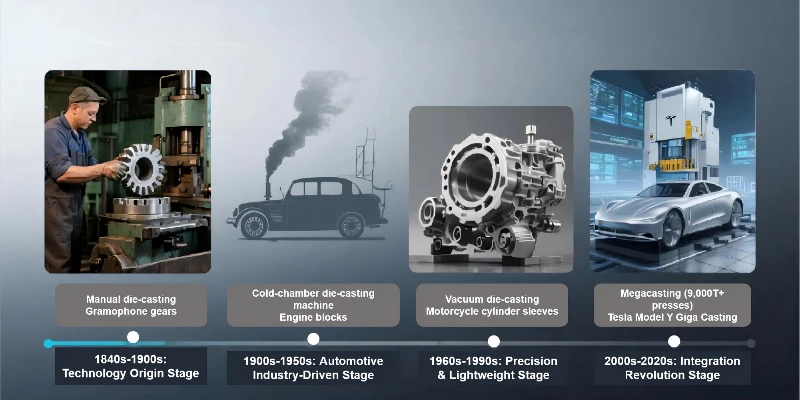

Die casting has evolved from producing small, simple zinc alloy parts to manufacturing large, complex aluminum structural components7. This change was driven by the industry’s demand for lighter, safer, and more fuel-efficient vehicles, especially with the rise of EVs.

In the early days of my career, we mostly focused on engine and transmission components. They were complex for their time, but nothing like what we do now. The real revolution has been driven by technology and new automotive challenges9. Computer-aided design (CAD10) and mold flow simulation allow us to perfect the part and the process on a screen before we ever cut steel. This saves time and prevents defects. The machines themselves have grown enormously in size and control, enabling us to make much larger parts. The development of new, high-performance aluminum alloys has also been a game-changer. These modern alloys offer the strength of steel at a fraction of the weight. This evolution has made die casting essential for building the next generation of vehicles.

| Aspect | Past (e.g., 1980s) | Present (e.g., 2020s) |

|---|---|---|

| Typical Part | Carburetor bodies, door handles | Full vehicle underbodies, shock towers |

| Material | Mostly zinc, some basic aluminum | High-performance, specialized aluminum alloys |

| Technology | Manual control, basic hydraulics | Fully automated, CNC control, vacuum-assist |

| Design Tool | 2D blueprints | 3D CAD and advanced mold flow simulation |

Why Is Aluminum the Preferred Material for Automotive Die Casting?

Wondering why everyone talks about aluminum die casting? While other metals can be used, aluminum has become the star player in the automotive world for several very important reasons.

Aluminum is the preferred material because it offers the best combination of strength, light weight, and corrosion resistance. It also has excellent thermal conductivity11, making it ideal for parts that manage heat, like in electric vehicles.

Weight is the enemy of efficiency. Making a car lighter improves its fuel economy or, in the case of an EV, its battery range. Aluminum is about one-third the weight of steel but can be engineered to be incredibly strong. This strength-to-weight ratio is its biggest advantage. But it doesn’t stop there. Aluminum naturally forms a protective oxide layer, so it doesn’t rust like steel. This is a huge benefit for parts exposed to the elements. For electric vehicles, its ability to quickly dissipate heat is critical. Battery enclosures and motor housings get hot, and aluminum helps keep these sensitive electronics cool and operating safely. In my experience with German and American Tier 1 suppliers, these three properties—lightweight, corrosion-resistant, and thermally conductive—make aluminum the default choice for nearly every new high-performance automotive component.

How Is Die Casting Applied to EV Battery Housings and Motor Components?

As cars go electric, are the manufacturing methods12 changing? Absolutely. Die casting has become even more critical for building the core components that power electric vehicles.

Die casting produces lightweight, complex, and thermally conductive enclosures for EV batteries and motors. It creates parts with thin walls and integrated cooling channels13, protecting the battery while also helping to manage its temperature for optimal performance.

Electric vehicles present unique challenges that die casting is perfectly suited to solve. The battery pack is the single heaviest and most important component. We use die casting to create large, tray-like enclosures that are both strong enough to protect the battery cells in a crash and light enough to maximize the vehicle’s range. A key innovation my team and I have worked on is casting cooling channels directly into the battery housing floor. Coolant flows through these channels to regulate battery temperature. This part consolidation14—turning multiple pieces into one—is a huge win. It eliminates potential leak points, simplifies assembly, and reduces cost. For motor and inverter housings, we do the same. We create complex, thin-walled shapes that are sealed tight to protect sensitive electronics from the elements while also drawing heat away.

What Are the Key Advantages of Die Casting Over Other Manufacturing Methods?

With so many ways to make a metal part, why is die casting so dominant in the auto industry? The answer lies in a unique combination of speed, precision, and cost-effectiveness15 at scale.

Die casting’s main advantages are its high production speed16, excellent dimensional accuracy17, and ability to create complex shapes8 with a smooth surface finish. For high volumes, it offers a lower unit cost than machining or sand casting.

Let’s look at how it stacks up against other common methods.

| Manufacturing Method | Speed | Complexity | Cost (High Volume) |

|---|---|---|---|

| Die Casting | Very High | High | Low |

| Sand Casting | Low | Medium | High |

| Machining from Billet | Very Low | Very High | Very High |

| Stamping | Very High | Low | Low |

Compared to sand casting, die casting produces parts with a much better surface finish and tighter tolerances, reducing the need for secondary machining. Compared to machining a part from a solid block of aluminum, die casting is exponentially faster and creates far less material waste. Stamping can be very fast, but it’s limited to forming sheet metal into simpler shapes. Die casting is the only process that delivers complex, three-dimensional parts at high speed. This combination is why it’s the go-to method for parts like transmission cases, oil pans, and the complex structural nodes of a vehicle’s frame.

How Does High-Pressure Die Casting Enable Complex Vehicle Geometries?

Ever wonder how carmakers produce those intricate, web-like metal parts? That level of detail and integration is made possible by the "high-pressure" aspect of High-Pressure Die Casting (HPDC).

High-pressure die casting forces molten metal into the mold at incredible speed and pressure. This allows the metal to flow into very thin sections and fill every complex detail of the part before it solidifies.

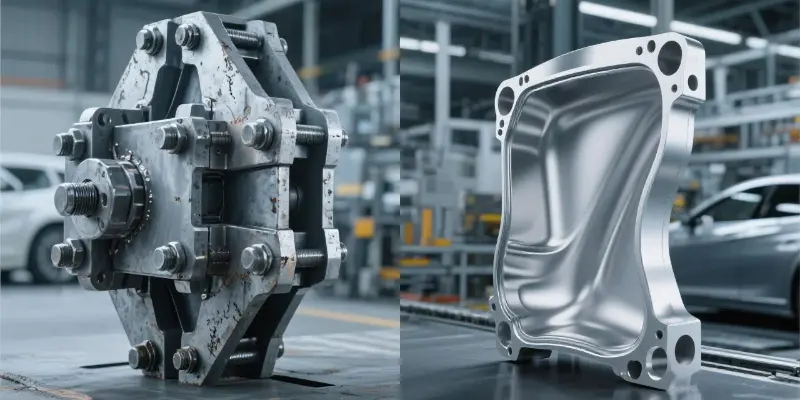

This process is what allows us to design parts with "net-shape" or "near-net-shape" features. This means the part comes out of the mold very close to its final form. We can design in reinforcing ribs, mounting bosses, and thin walls all in one shot. I’ve worked on projects where we consolidated what was once an assembly of ten different stamped and welded steel pieces into a single, lightweight aluminum die casting. This kind of part consolidation is a dream for automotive designers. It reduces weight, eliminates several assembly steps on the production line, and creates a stronger, more rigid final part because there are no joints or welds, which can be points of weakness. High pressure is the key that unlocks this level of design freedom and efficiency.

What Role Does Die Casting Play in Lightweighting Strategies for Vehicles?

Why is every carmaker obsessed with "lightweighting"? Because a lighter car is a more efficient car. Die casting is one of the most important tools we have to achieve this.

Die casting plays a central role in lightweighting by enabling the use of strong but light aluminum alloys to replace heavy steel components. It also allows for the creation of optimized, thin-walled designs and part consolidation.

Lightweighting is not just about swapping one material for another. It is about smart design. The true power of die casting in this area comes from two things. First, material substitution. We can replace a heavy steel component with a much lighter aluminum one that delivers the same or even better performance. Second, design optimization. Because die casting allows us to create complex shapes, we can put material only where it is needed for strength and take it away from areas that are not under stress. This results in parts that look more organic and skeletal than blocky, and they are incredibly efficient in their use of material. For an internal combustion engine car, lightweighting means better MPG. For an electric vehicle, it is even more critical—it means longer range on a single charge.

How Will Die Casting Technologies Shape the Future of the Automotive Industry?

Thinking die casting has reached its peak? The technology is advancing faster than ever. The next wave of innovation is already here, and it is changing how cars are designed and built.

Future die casting technologies like "giga casting18" will allow for the production of entire vehicle sections as a single piece. This reduces assembly complexity, factory footprint, and cost, fundamentally reshaping automotive manufacturing.

The most talked-about innovation right now is giga casting. This involves using enormous die casting machines, or Giga Presses, to cast huge sections of a car’s body, like the entire front or rear underbody, as one part. This can replace 70 or more individual stamped parts and eliminate hundreds of robots used for welding. It’s a massive leap in manufacturing efficiency. Beyond that, we are seeing major advances in materials science with new alloys that are stronger and more ductile. We are also improving the process with technologies like vacuum-assisted casting, which removes air from the mold cavity before injection. This reduces porosity and creates parts strong enough for critical safety applications. As an engineer, it’s an exciting time. We are moving from making components to making entire vehicle systems with this technology.

Conclusion

Die casting is more than just a process; it’s a key enabler for modern automotive innovation. It’s how we build lighter, stronger, and more efficient cars for today and tomorrow.

-

Explore the significance of lightweighting in enhancing vehicle efficiency and performance. ↩

-

Learn how die casting is revolutionizing the automotive industry with lightweight and strong components. ↩

-

Explore the fundamentals of die casting and its significance in automotive manufacturing. ↩

-

Discover the advantages of aluminum in die casting and its impact on vehicle performance. ↩

-

Understand the benefits of high-pressure die casting in producing complex automotive parts. ↩

-

Learn about the production of engine blocks through die casting and its benefits. ↩

-

Discover the various structural components in vehicles that are produced via die casting. ↩ ↩

-

Find out how die casting enables the production of intricate automotive components. ↩ ↩

-

Learn how die casting meets the evolving challenges in modern automotive design. ↩

-

Find out how computer-aided design enhances the efficiency and accuracy of die casting. ↩

-

Learn how thermal conductivity of materials affects the performance of automotive components. ↩

-

Compare die casting with other methods to see why it’s preferred in automotive production. ↩

-

Discover the innovative design of cooling channels in die-cast parts for thermal management. ↩

-

Understand how part consolidation simplifies manufacturing and enhances component strength. ↩

-

Understand the cost benefits of die casting in high-volume automotive manufacturing. ↩

-

Compare the production speed of die casting with other manufacturing techniques. ↩

-

Explore why dimensional accuracy is crucial for the quality of die-cast automotive parts. ↩

-

Explore the future of automotive manufacturing with giga casting technology. ↩