Struggling to produce precise, complex metal parts quickly and affordably? Traditional methods can be slow and costly. Die casting offers a powerful solution for high-volume manufacturing.

Die casting is widely used because it delivers exceptional dimensional accuracy1, complex shapes2, and a smooth surface finish at very high production speeds. This combination makes it extremely cost-effective3 for producing large quantities of parts with minimal secondary operations, making it a go-to process for many industries.

From automotive components4 to electronics housings, the benefits of die casting are clear to engineers and procurement managers. But to really understand its value, you need to see how it stands up against other manufacturing methods and where it truly shines. In my 20 years on the factory floor and working with global customers, I’ve seen firsthand why it’s a core process for modern production. It all comes down to a unique blend of speed, precision, and cost-effectiveness that is difficult to match.

What are the main advantages of die casting in manufacturing?

Choosing the right manufacturing process for a new project is critical. Making the wrong choice can lead to higher costs, quality problems, and project delays. Understanding die casting’s core benefits is key.

The main advantages are high-speed production cycles5, excellent dimensional precision for complex net-shape parts, and a superior surface finish6. This blend of features means you can create intricate components7 quickly and affordably, often with little to no post-processing required.

When a Tier 1 customer comes to me with a new project, they are almost always trying to solve for cost, weight, and performance at the same time. Die casting is often the answer because of three powerful advantages that I have relied on throughout my career.

Speed and Production Efficiency

The die casting process is incredibly fast. A complete production cycle, from injecting the molten metal to ejecting a solid part, can take just seconds. For high-volume projects, this means we can produce thousands, or even hundreds of thousands, of identical parts very quickly. This high rate of production directly translates to a lower cost per part, which is a huge factor for industries like automotive.

Complexity and Precision

Die casting allows us to create very complex shapes with a high degree of accuracy. We can design parts with thin walls, fine details, and internal features that would be very difficult or expensive to create with other methods. We call this "net-shape" or "near-net-shape" manufacturing. This means the cast part comes out of the mold very close to its final form, which drastically reduces the need for expensive and time-consuming machining later.

Superior Surface Finish

Parts made through die casting have a very smooth and consistent surface finish. For many applications, the part is ready for use right out of the mold. For parts that need a decorative or protective coating, this smooth surface provides an excellent base for painting, plating, or powder coating with minimal preparation.

How does die casting compare to other metal forming methods?

With so many metal forming options available, it can be confusing. Forging, machining, and sand casting all have their place. Picking the wrong one can lead to blown budgets and missed deadlines.

Die casting excels at producing intricate, thin-walled parts at high speed, unlike forging, which is better for ultimate strength. It is far more precise than sand casting and more durable than plastic injection molding, offering a unique and versatile balance of properties.

Engineers and procurement managers often ask me, "Why should we use die casting for this part instead of something else?" It’s a great question. The best choice always depends on the specific needs of the project: volume, complexity, strength requirements, and budget. Each process has its strengths. I’ve found that a simple comparison helps my clients make the right call for their projects.

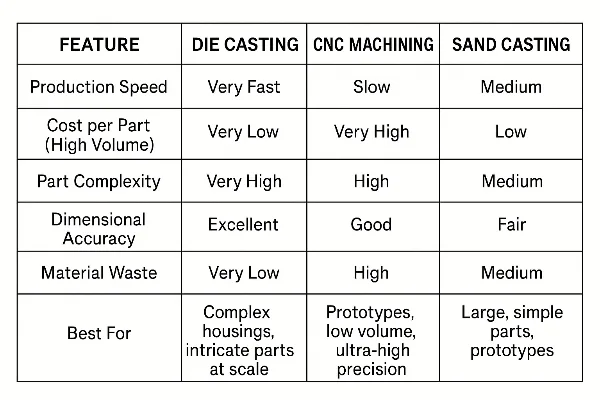

Here is a quick table I often use to explain the differences:

As you can see, die casting hits a sweet spot. It’s the ideal choice when you need to produce a large volume of complex, precise parts cost-effectively. For the high-voltage connectors and EV motor housings my team works on, no other process offers this combination of benefits.

What types of parts are best suited for die casting?

Die casting is a powerful process, but it is not the right choice for every part. Using it for the wrong application can lead to design compromises or unexpected costs. Knowing its sweet spot is key.

Parts best suited for die casting are high-volume components8 that require complex geometries, thin walls, and good dimensional stability9. Think of housings, enclosures, and brackets for the automotive, consumer electronics, and telecommunications industries where precision and cost matter.

When I’m working with a customer on DFM (Design for Manufacturability) analysis, we are laser-focused on whether the part’s features align with what die casting does best. In my experience, especially with the shift to electric vehicles10, certain categories of parts are a perfect match.

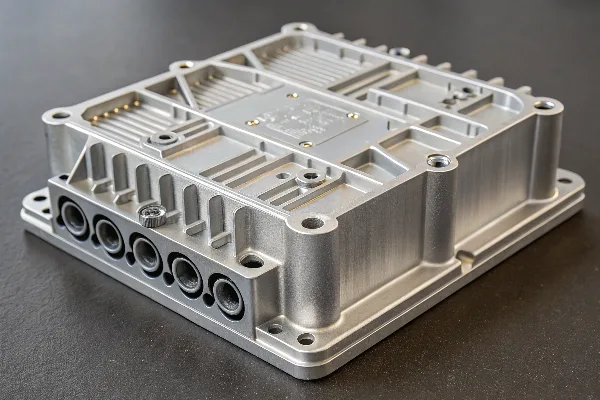

Housings and Enclosures

This is the classic application for die casting. Parts like motor controller housings, on-board charger (OBC) casings, and electronics enclosures are ideal. Why? Because they need to be lightweight, dissipate heat, and often provide EMI shielding11. Die casting allows us to create thin walls to save weight and integrate complex features like cooling fins12 and mounting bosses directly into the part, saving assembly time and cost.

Structural Components

In the past, die casting was not always the first choice for structural parts due to strength concerns. But that has changed. With advancements like vacuum casting13 and new high-strength alloys, we are now producing critical structural parts. For example, we make shock tower housings and vehicle cross-members that need to be both lightweight and strong enough to handle structural loads.

Parts with High Aesthetic Requirements

Because of the smooth surface finish, die casting is great for parts where appearance matters. Think of components in a car’s interior, high-end appliance casings, or any part that the end user will see and touch. The process delivers a premium look and feel without a lot of extra work.

How has die casting technology evolved to meet modern demands?

Traditional die casting had some well-known limits, like hidden porosity. For today’s demanding EV components, which face higher thermal and mechanical stresses, these old flaws are simply not acceptable.

Recent advancements like AI-driven simulation14 and hybrid casting processes15 are overcoming traditional limitations. These innovations predict and prevent defects like porosity and enable aluminum parts to achieve tensile strengths16 that rival much heavier materials, satisfying strict new automotive standards.

The die casting I learned on the shop floor 20 years ago is not the same process we use today. The industry has been transformed by technology, especially in response to the challenges of electric mobility. As I’ve shared with my partners at German and American Tier 1s, these aren’t just minor tweaks; they are game-changing innovations that address the core limitations of the past.

Predictive Quality with AI-Driven Simulation

Mold flow simulation used to be a simple tool to check if a mold would fill. Today, it’s a sophisticated predictive powerhouse. The newest simulation software, driven by AI, can now model and predict microstructural defects before we even start building the mold. For one of our EV battery casing projects, we used it to identify a high-risk area for porosity right where a critical weld was needed. By adjusting the mold design based on the simulation, we completely engineered the problem out. This level of precision is why some of our clients see rework rates fall by up to 40%. It is a strategic shift from finding defects to preventing them.

Bridging the Strength Gap with Hybrid Processes

The biggest historical tradeoff with aluminum die casting was strength versus weight. Now, new hybrid technologies are closing that gap. We are using processes that combine high-pressure injection with localized squeeze casting or semi-solid forming. This allows us to create parts that are incredibly light but also incredibly strong. We are now consistently producing aluminum structural parts that achieve tensile strengths approaching 450 MPa. For our automotive clients, this means they can meet tougher crash safety standards without adding weight, which is essential for maximizing EV range.

Conclusion

Die casting remains a dominant process because it continuously evolves, offering unmatched speed and precision. Now, new technology provides the advanced material properties needed for today’s most demanding applications.

-

Understanding dimensional accuracy is crucial for ensuring high-quality production and meeting design specifications. ↩

-

Explore how die casting achieves complex shapes, enhancing design possibilities and production efficiency. ↩

-

Discover the cost benefits of die casting and how it can save money in high-volume production. ↩

-

Explore how die casting benefits the automotive industry through efficiency and precision. ↩

-

Learn about high-speed production cycles and their impact on manufacturing efficiency and cost reduction. ↩

-

Explore the importance of surface finish in die casting and its impact on product quality. ↩

-

Find out how intricate components are produced and their significance in various industries. ↩

-

Discover the characteristics of high-volume components and their relevance in production processes. ↩

-

Learn about dimensional stability and its role in ensuring the quality of manufactured parts. ↩

-

Explore the role of die casting in the production of electric vehicles and its benefits for the industry. ↩

-

Discover the importance of EMI shielding in electronics and how die casting can provide effective solutions. ↩

-

Explore the role of cooling fins in design and their significance in thermal management. ↩

-

Learn about vacuum casting and its advantages in producing high-quality parts. ↩

-

Discover how AI-driven simulation enhances die casting processes and reduces defects. ↩

-

Explore hybrid casting processes and their role in improving material properties and production efficiency. ↩

-

Understanding tensile strengths is crucial for evaluating material performance in manufacturing. ↩