Confused by casting terms? Choosing the wrong process creates defects and project delays. HPDC might be the perfect solution you need for your complex and high-volume components.

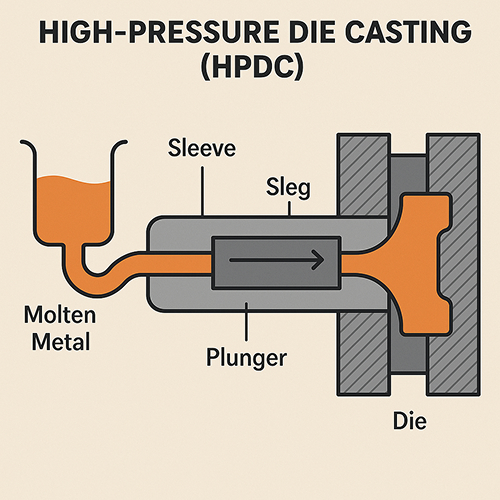

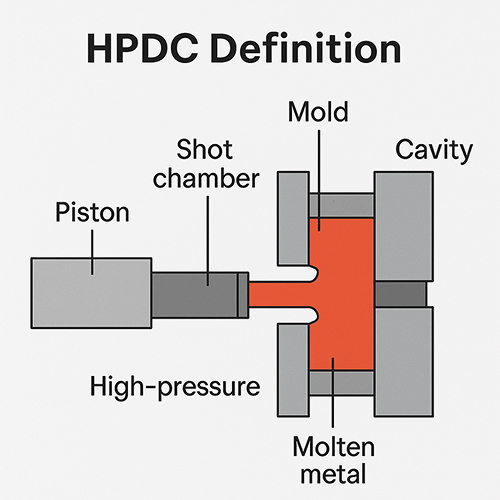

High-Pressure Die Casting (HPDC) is a manufacturing process that forces molten metal, like aluminum alloy, into a steel mold under very high pressure. It is ideal for mass-producing complex parts with high precision and an excellent surface finish, especially for the automotive industry.

I have worked with die casting for over two decades, and HPDC is a process I know inside and out. It is a powerful manufacturing method, but the name itself can be the first hurdle for many of our partners. Many clients, from procurement directors to quality engineers, ask me what these different acronyms mean. To make confident decisions, you need to be clear about the basics. Let’s break down the terminology and compare HPDC with other common casting methods. This will give you a stronger foundation for your next project.

What does HPDC mean?

Do casting acronyms cause confusion in your technical discussions? This can lead to costly mistakes with suppliers. Let’s define HPDC to ensure everyone on your team is on the same page.

HPDC stands for High-Pressure Die Casting. It is a metal casting process that uses high pressure to inject molten metal into a reusable mold, called a die. This method is perfect for mass-producing intricate parts with thin walls, like motor housings or OBC housings for EVs.

The name "High-Pressure Die Casting" tells you exactly what it does, but let’s look at each part more closely. The "High-Pressure" component is the most critical. We apply pressures that usually range from 10 to over 100 megapascals (MPa). This incredible force pushes the molten metal into every tiny detail of the mold cavity. This is why it works so well for parts with complex geometries. From my experience developing new energy vehicle components, this high pressure is essential for achieving the high airtightness required for motor controller housings. The "Die Casting" part refers to the tool itself—a hardened steel mold, or die. These dies are very durable and can be used for hundreds of thousands of production cycles. This makes HPDC extremely cost-effective for high-volume manufacturing.

| Feature | Description | Common Application Example |

|---|---|---|

| Material | Aluminum alloys (e.g., ADC12, A380), Magnesium, Zinc | Automotive powertrain components |

| Process | Rapid injection of molten metal under high pressure into a steel die. | Electronic enclosures, motor housings |

| Key Advantage | Excellent for complex, thin-walled parts with a great surface finish. | Mechanical parts with high precision |

What is LPDC and HPDC?

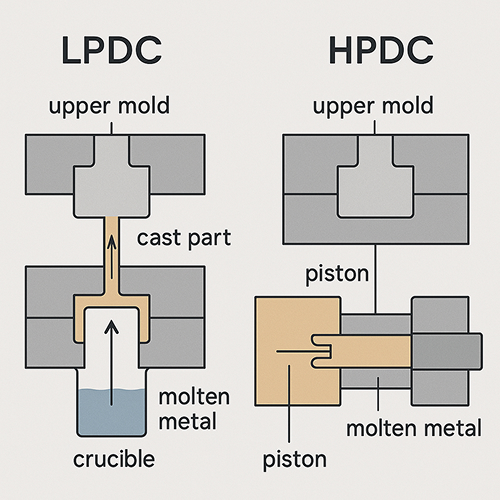

Are you choosing between LPDC and HPDC for your project? The difference in pressure might seem small, but this choice dramatically impacts part quality, tooling costs, and production speed.

LPDC (Low-Pressure Die Casting) uses low pressure to fill the mold slowly from the bottom up. This reduces turbulence and porosity, creating dense, high-integrity parts. HPDC uses high pressure for rapid filling, which is ideal for complex, thin-walled parts at high volumes.

The core difference between Low-Pressure and High-Pressure Die Casting is how the molten metal enters the mold. At EMP Tech, we have deep expertise in both processes. With LPDC, we push the molten metal gently into the mold cavity from below. Imagine slowly filling a glass of water from the bottom; the process is calm and minimizes air entrapment. This makes LPDC excellent for parts that need high structural integrity and must be heat-treatable, like vehicle wheels or suspension arms. HPDC, on the other hand, is like firing a water jet. The fill is extremely fast and aggressive. This speed is perfect for creating very thin walls and complex features before the metal solidifies. However, this turbulence can trap air, which may create some porosity. For a quality engineer responsible for part performance, this is a critical point. We manage this risk through advanced mold flow simulation and very careful process control.

| Aspect | LPDC (Low-Pressure Die Casting) | HPDC (High-Pressure Die Casting) |

|---|---|---|

| Pressure | Low (0.02-0.15 MPa) | High (10-100+ MPa) |

| Fill Speed | Slow, controlled | Extremely fast, turbulent |

| Porosity | Minimal, results in dense parts | Can be present, requires careful process control |

| Heat Treatable | Yes | Generally not recommended |

| Best For | Structurally sound parts, wheels, suspension components | Complex, thin-walled parts, housings, covers |

What is the difference between HPDC and GDC?

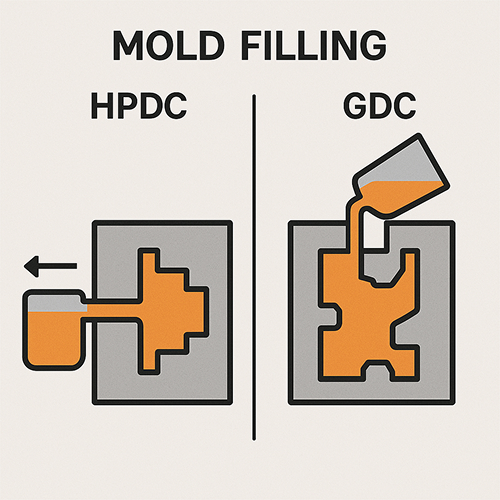

Is Gravity Die Casting a viable alternative to HPDC for your components? They sound similar, but their capabilities, costs, and applications are worlds apart. Knowing the key distinctions is essential.

GDC (Gravity Die Casting), also called permanent mold casting, relies only on gravity to fill the mold. It is slower and produces thicker, less complex parts than HPDC. HPDC uses high pressure for fast cycles, thin walls, and intricate designs, making it better for high volumes.

Gravity Die Casting (GDC) is the most straightforward of these die casting methods. As its name suggests, it uses only the natural force of gravity to fill the mold. I often explain it to my clients as being similar to pouring pancake batter into a pan. The metal flows slowly and gently, which results in parts with good mechanical properties and low porosity. Because the process is much simpler, the tooling for GDC is less expensive and has shorter lead times than HPDC tooling. However, the cycle times are much longer, which makes GDC less suitable for very high-volume production runs. HPDC is completely different because it uses immense pressure. This force allows us to produce parts at a much faster rate, often in seconds. It also lets us create features that are impossible with GDC, like walls as thin as 1.5mm and very fine surface details. When a project has tight schedules and high volumes, HPDC is almost always the superior choice.

| Factor | GDC (Gravity Die Casting) | HPDC (High-Pressure Die Casting) |

|---|---|---|

| Filling Force | Gravity | High mechanical pressure |

| Cycle Time | Slower (minutes per part) | Faster (seconds per part) |

| Tooling Cost | Lower | Higher |

| Part Complexity | Simpler shapes, thicker walls | Complex shapes, thin walls, fine details |

| Typical Volume | Low to medium | High |

What is the difference between squeeze casting and HPDC?

Have you heard of squeeze casting? You might wonder if it is a better choice than HPDC for your most critical parts. It is a specialized process with unique benefits.

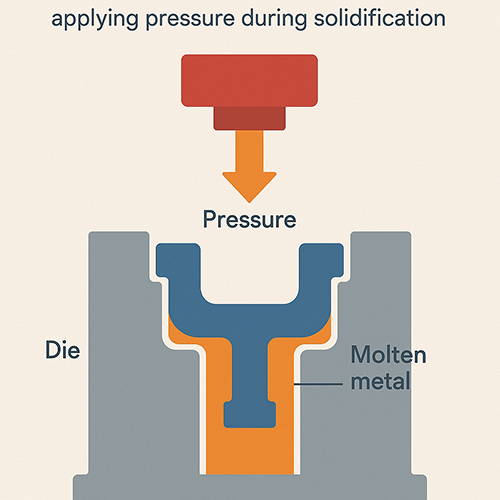

Squeeze casting is a hybrid process combining casting and forging. It applies high pressure to the molten metal as it solidifies, creating virtually pore-free parts with superior strength. HPDC injects metal at high speed, while squeeze casting applies pressure slowly during solidification.

Squeeze casting is a fascinating process that I have used for some of the most demanding automotive projects. I describe it as a hybrid method that combines the shaping ability of casting with the material refinement of forging. Unlike HPDC, where pressure injects the metal quickly, in squeeze casting, we fill the mold slowly and then apply immense pressure as the metal solidifies. This "squeezing" action eliminates gas porosity and shrinkage voids. The result is a part with a forged-like microstructure and outstanding mechanical properties—far superior to what standard HPDC can achieve. This makes it a perfect process for safety-critical components, like suspension knuckles or brake calipers, where failure is not an option. For a supplier quality engineer, specifying squeeze casting ensures the highest possible material integrity. The main trade-off is that the process is slower and more expensive than HPDC.

| Characteristic | Squeeze Casting | HPDC (High-Pressure Die Casting) |

|---|---|---|

| Process Type | Hybrid (Casting + Forging) | Pure Casting |

| Pressure Applied | During solidification | During injection/filling |

| Porosity Level | Virtually zero | Low, but can be present |

| Mechanical Properties | Excellent, forged-like strength and ductility | Good, but lower than squeeze casting |

| Ideal For | Safety-critical, high-strength parts | Complex, high-volume parts where cost is a factor |

Conclusion

In short, HPDC is a fast, cost-effective process for complex parts. Understanding its differences from LPDC, GDC, and squeeze casting helps you choose the right manufacturing method for your project.