Struggling with heavy, complex parts that delay your projects? Ignoring die casting means higher costs, slower production, and falling behind in the competitive EV market.

Aluminum die casting solves these challenges by producing strong, lightweight, and complex parts at high speed. This process allows for part consolidation, which improves vehicle efficiency, simplifies assembly, and ultimately lowers your total manufacturing costs.

Over my 20 years in this field, I have seen the automotive industry’s demands evolve firsthand. I’ve gone from working on simple brackets to leading projects for massive electric vehicle subframes. A Global Procurement Director from Germany once told me his biggest challenge was balancing cost, weight, and a tight launch schedule for a new EV platform. He was managing dozens of suppliers for a single welded assembly. We showed him how a single die-cast part could solve all three problems at once. This is the power of die casting. It is not just about making a component; it is about providing an engineering solution1 that gives our clients a competitive edge.

How does the aluminum die casting process actually work?

Feeling disconnected from the manufacturing floor? Not knowing the process details can lead to design flaws and miscommunication with your suppliers, causing frustrating delays for everyone.

The process forces molten aluminum into a hardened steel mold, called a die, under extremely high pressure. The metal cools and solidifies in seconds, after which the die opens and the precise, near-net-shape part is ejected.

When I was starting out on the shop floor, I spent countless hours adjusting die casting machines. I learned that it is a process of controlled violence. You are injecting liquid metal at incredible speeds and pressures. Every single parameter matters. The temperature of the metal, the speed of the injection plunger, and the cooling rate of the die must be perfect to create a sound part. Here is a simple breakdown of what happens:

- Melting and Dosing: We start with high-purity aluminum alloy2 ingots, melt them in a furnace, and transfer a precise amount—a "shot"—for each cycle.

- Injection: The die is securely clamped shut. Then, a plunger injects the molten aluminum into the die cavity in just a fraction of a second.

- Solidification: As soon as the cavity is filled, the metal begins to cool rapidly against the steel die walls. This quick cooling is what creates the fine grain structure and excellent mechanical properties.

- Ejection: Once solid, the die opens, and ejector pins push the casting out.

- Extraction: A robot typically removes the hot casting and places it into a quench tank or a trim press.

This entire cycle is very fast, often taking less than two minutes for even a large, complex part.

What are the real benefits of using aluminum die casting for auto parts?

Are your designs being compromised by manufacturing limitations? Using older, traditional methods can lead to heavier parts, more assembly steps, and a higher overall cost for your project.

The key benefits are significant weight reduction for better efficiency, the ability to create complex geometries that consolidate multiple parts into one, high-speed production for scalability, and an excellent, smooth surface finish.

These benefits are not just theoretical; they have a real impact on our customers’ projects. Let’s look at them more closely.

The Core Advantages

| Benefit | Impact on Automotive Projects | My Experience |

|---|---|---|

| Weight Reduction | Improves EV range and vehicle handling. A lighter car is more efficient and safer. | We replaced a 22 kg steel subframe with a 14 kg aluminum casting for an Italian supplier, helping them meet their vehicle weight target. |

| Part Consolidation | Reduces assembly time, lowers labor costs, and eliminates potential failure points like welds and fasteners. | For a US client, we designed a single die-cast shock tower that replaced an assembly of over 20 stamped and welded steel pieces. |

| Speed & Scalability | High-volume production rates with consistent quality, ideal for the scale of the automotive market. | Our automated cells can produce thousands of identical parts per day, ensuring a stable supply chain for our customers’ assembly lines. |

| Precision & Complexity | Allows for thin walls, integrated cooling channels, and complex mounting features directly in the casting. | We regularly produce inverter housings with wall sections as thin as 2.5 mm, which is critical for heat dissipation and weight goals. |

These advantages are why die casting is the go-to technology for so many critical EV and modern automotive components.

What services are included in a full die casting solution?

Are you juggling multiple vendors for design, tooling, finishing, and assembly? This fragmented approach creates communication gaps, schedule overruns, and finger-pointing when problems arise.

A full, end-to-end solution includes everything from early design analysis (DFM) and mold manufacturing to casting production, precision CNC machining, surface treatments, and even some light assembly. It is a true one-stop-shop partnership.

I’ve found that the most successful projects are the ones where we are involved from the very beginning. We do not just take a finished design and make a tool. We partner with our clients’ engineering teams to optimize their part for manufacturing. Our services are designed to be a seamless extension of their own capabilities.

- Design for Manufacturability (DFM)3 & Mold Flow: Before any steel is cut, we analyze the part design. We use mold flow simulation software to predict how the metal will fill the die, where potential porosity might occur, and how to prevent it. This saves countless hours and prevents costly tool modifications later.

- In-House Mold Manufacturing: We design and build our own tools. This control is critical. It allows us to manage timelines tightly and ensure the mold is built to the highest standard for a long production life.

- High-Pressure Die Casting (HPDC): This is our core production process. With 17 machines ranging from 350 to 3050 tons of locking force, we have the flexibility to produce a wide range of part sizes.

- Post-Casting Solutions: A raw casting is rarely the final product. We have a full CNC machining shop to create high-precision surfaces and features. We also manage various surface treatments4, like powder coating or chromate conversion, through trusted partners to deliver a fully finished product.

This integrated approach gives our clients one point of contact and total accountability.

How do you guarantee quality and precision in every single casting?

Are you worried about quality defects5 reaching your assembly line? A single bad part can cause costly shutdowns, field failures, and serious damage to your company’s reputation for reliability.

Quality is guaranteed through a robust system that combines real-time process monitoring, advanced inspection technologies like CMM and X-ray, and strict adherence to the IATF 16949 automotive quality standard. Quality is built-in, not inspected-in.

As a technical engineer, this is what I am most passionate about. For a Supplier Quality Engineer, seeing our quality system in action provides immediate confidence. Our IATF 169496 certification is not just a piece of paper; it is the foundation of our entire operation. It means that every step, from how we handle raw materials to our final inspection and shipping process, is documented, controlled, and continuously improved. We monitor dozens of parameters on every machine cycle in real time. If a variable goes out of specification, the system alerts us immediately. We then use advanced tools to verify the results. Our Coordinate Measuring Machines (CMM) check dimensional accuracy down to the micron. Our X-ray machines let us see inside the casting to ensure there is no hidden porosity. For critical components like battery housings, we perform 100% leak testing. This multi-layered system ensures that the parts we ship meet not just the drawing specifications, but also our customers’ highest expectations for quality and reliability.

What makes a die casting supplier a truly reliable partner?

Are you tired of suppliers who just take orders and disappear when there is a problem? A lack of proactive communication and engineering support can leave you to solve critical issues on your own.

A reliable partner offers more than just parts. They provide deep engineering expertise, proactive communication, modern and scalable equipment, and incredibly responsive service to ensure your project’s total success.

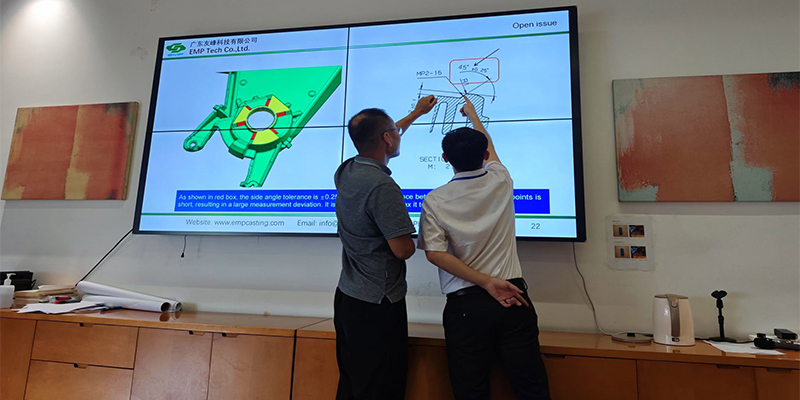

Over the years, I have seen that the best supplier relationships are built on trust and partnership. It is what we strive for at EMP Tech. Our clients in the automotive industry face immense pressure, and our job is to be an extension of their team and a resource they can depend on. We stand out because we focus on three key areas.

First, engineering expertise. My team and I come from a technical background. We help our customers solve design challenges before they become production problems. Second, capability and capacity. Our 17 die casting machines7, ranging from 350T all the way up to 3050T, give us the flexibility to handle a huge variety of parts, from small electronic housings to massive structural components. This range of equipment means we can support our clients’ needs as their products evolve. Finally, responsiveness. We operate on a 24/7 basis because we know that global supply chains never sleep. When a client in Germany sends an email at the end of their day, our team is here to answer it. This commitment to service is what turns a transaction into a true partnership.

Conclusion

Choosing the right die casting partner provides more than just components. It secures a competitive edge through lightweight, high-quality engineering and a reliable, end-to-end manufacturing service.

-

Understand what makes an engineering solution effective in addressing manufacturing challenges. ↩

-

Learn about the advantages of using high-purity aluminum alloys in die casting applications. ↩

-

Find out how DFM can optimize product designs for better manufacturing outcomes. ↩

-

Discover various surface treatments and their importance in enhancing product durability. ↩

-

Find out how to identify and prevent quality defects in die casting processes. ↩

-

Understand the importance of IATF 16949 certification in ensuring automotive quality standards. ↩

-

Explore the various types of die casting machines and their applications in manufacturing. ↩