Struggling to keep up with industry shifts? The automotive world is changing fast, and keeping projects competitive and on time is a constant challenge for lightweight parts.

For 2025, the key trends are the increased adoption of aluminum driven by EVs and stricter emission rules. Expect big advances in high-pressure die casting, a push for sustainable alloys, and massive growth in EV-specific components. Asia Pacific and North America will lead this global expansion.

The automotive industry is moving faster than ever. As an engineer who has been in die-casting for over 20 years, I see these trends not just as headlines but as real-world challenges on the factory floor and in design meetings. The demand for lightweight, high-performance parts is relentless. Carmakers need to squeeze every bit of efficiency out of their vehicles, whether they run on gasoline or electricity. This pressure flows down to Tier 1 and Tier 2 suppliers, who must innovate to survive. Let’s break down the major trends shaping our industry and what they mean for your projects.

Why is the Rising Demand for Lightweight Vehicles Driving Aluminum Adoption?

Your customers demand lighter, more efficient cars. Finding materials that cut weight without hurting strength is tough. Aluminum die-casting is the solution you’ve been looking for.

Aluminum is the top choice for lightweighting because it gives an excellent strength-to-weight ratio. This improves fuel efficiency in gas cars and extends the range of electric vehicles. It’s the most practical way automakers can meet performance and regulatory targets today.

In my work, I see this shift every day. A few years ago, my team worked with a major Canadian supplier on a new crossover SUV. The goal was to reduce the weight of the front subframe. The original steel part was durable but very heavy. We collaborated on a complete redesign using a high-strength aluminum alloy. Through detailed design for manufacturability (DFM) analysis and mold flow simulations, we showed them how a die-cast aluminum part could work. The final result was a subframe that was 40% lighter but met all the same safety and performance standards. This weight saving translated directly to better fuel economy for the vehicle. This is not just about replacing one material with another. It’s about rethinking the entire part design to take full advantage of what aluminum offers. We can integrate features like mounting brackets directly into the casting, which simplifies the assembly line and reduces the total number of parts. It’s a win-win for everyone involved.

What are the Advancements in High-Pressure Die-Casting Technologies?

You face constant pressure to produce complex parts with zero defects. Old die-casting methods can lead to porosity and other quality issues, causing delays and cost overruns.

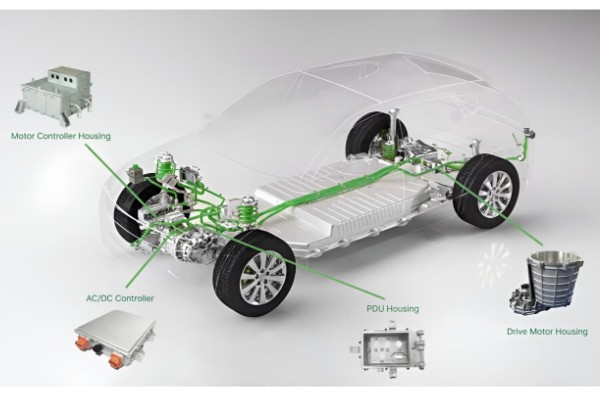

New high-pressure die-casting (HPDC) technologies like vacuum-assisted and semi-solid casting are changing the game. They produce parts with higher density, better mechanical properties, and fewer internal defects. This means stronger, more reliable components for critical applications like chassis and battery enclosures.

I remember a challenging project developing a motor controller housing for a German Tier 1 supplier. The part had extremely strict airtightness requirements because any leak could compromise the electronics inside. Standard HPDC was leaving tiny gas porosity, causing failures during pressure testing. My team and I decided to use vacuum-assisted high-pressure die casting1. By pulling a vacuum in the mold cavity just before injecting the aluminum, we removed most of the trapped gases. This dramatically reduced porosity and improved the material’s integrity. The result was a pass rate of over 99.5% on the airtightness tests, which was a huge success for the customer. These advanced technologies are not just optional upgrades anymore. For parts with high-performance demands, they are essential.

| Technology | Key Benefit | Ideal Application |

|---|---|---|

| Vacuum-Assisted HPDC | Reduces gas porosity, improves surface finish. | Airtight housings, safety-critical parts. |

| Semi-Solid Casting | Creates a fine a grain structure, enhances strength. | Structural components, suspension parts. |

| Real-Time Process Control | Monitors and adjusts injection parameters instantly. | All complex parts requiring high consistency. |

How is Sustainability Shaping the Use of Low-Carbon Aluminum Alloys?

Your company faces growing pressure to build a green supply chain. Sourcing sustainable materials without sacrificing quality or increasing costs is a major challenge for procurement teams.

Sustainability is driving a major shift toward low-carbon and recycled aluminum. Automakers and suppliers are now demanding materials with a smaller carbon footprint. This trend supports circular economy goals and helps meet corporate environmental targets, which is becoming a key factor in supplier selection.

Last year, we started working with a U.S. company that produces components for electric vehicles2. Their procurement director was very clear from the start: they needed to document the carbon footprint3 of every part. My team helped them select a secondary aluminum alloy, which is made from recycled material. This type of aluminum uses up to 95% less energy to produce than primary aluminum made from bauxite ore. We provided full traceability for the material, showing its recycled content and the associated CO2 savings. This wasn’t just a "nice-to-have"; it was a core requirement for winning the contract. We are now seeing this from more and more customers, especially from Europe. They want partners who can not only deliver quality parts on time but also help them meet their sustainability goals. It’s a new and important part of being a trusted manufacturing partner.

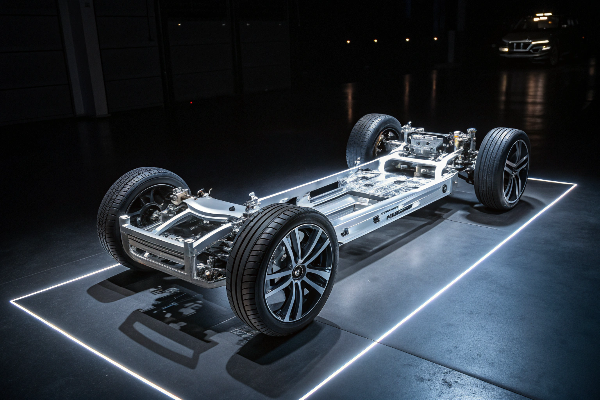

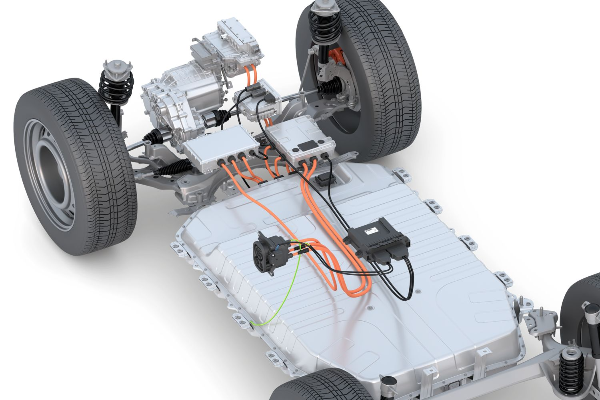

What is the Impact of Growth in Electric Vehicle Production?

Electric vehicles require unique, complex components. Developing them under tight project timelines is a huge challenge, especially when they have high thermal and structural requirements.

The growth of EVs is creating massive demand for aluminum die-cast parts like battery enclosures, motor housings, and power electronics casings. Aluminum is perfect for these applications because it is lightweight, strong, and has excellent thermal conductivity to help with heat management.

My team and I recently led the development of a large battery enclosure for a new electric sedan. This was a "giga-casting4," a very large, single-piece structural component. The part needed to be incredibly strong to protect the battery cells in a crash, but also lightweight to maximize the vehicle’s range. It also had complex internal channels for a liquid cooling system. We used extensive mold flow simulation to get the casting process right. We had to manage how the molten metal filled a very large, complex mold without creating defects. We worked closely with the customer’s engineers from the earliest design stages. This early collaboration was key to making the project a success. The finished part combined the functions of dozens of smaller stamped steel parts into one, saving weight, cost, and assembly time. It showed how aluminum die-casting5 is not just a component choice, but a core enabler of modern EV design.

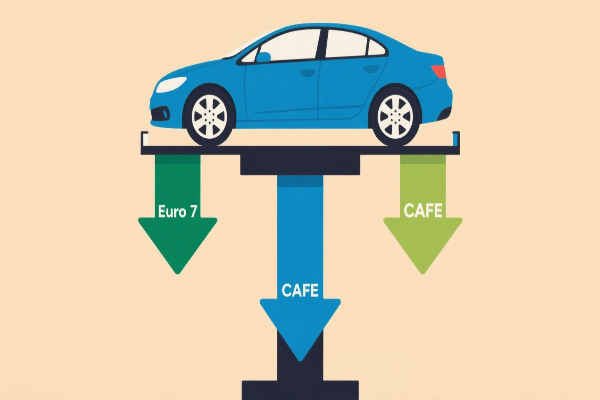

How do Stringent Fuel Efficiency and Emission Regulations Impact Aluminum Use?

Regulations keep getting tougher. Meeting new emission and fuel economy standards forces you to find innovative ways to make every part of the vehicle more efficient.

Strict regulations like the CAFE standards in the U.S. and Euro 7 in Europe are a primary driver for using aluminum. Reducing vehicle weight with aluminum is one of the most effective strategies to lower fuel consumption and cut CO2 emissions for internal combustion engine vehicles.

I’ve seen firsthand how these regulations directly influence engineering decisions. A few years back, we were helping an Italian Tier 1 supplier with a new transmission housing. The automaker’s main goal was to shave grams off every component to meet a new fleet-wide CO2 target in Europe. The old housing was a standard aluminum casting, but we found ways to optimize it further. Using advanced topology optimization6 software, we identified areas where we could remove material without compromising strength. We refined the rib patterns and wall thicknesses. In the end, we reduced the part’s weight by an additional 15%. This might not sound like much, but when you do this across dozens of components, the total weight savings add up significantly. These regulations create a powerful incentive for continuous improvement and push us to be more creative with our engineering.

What are the Regional Market Insights for Aluminum Die-Casting?

You are managing a global supply chain. You need to know where the growth is happening and where to find capable suppliers to support your worldwide operations.

The Asia Pacific region, led by China, is the fastest-growing market due to its massive EV production. North America is also seeing strong growth, driven by investments in domestic EV manufacturing and reshoring trends. Both regions are hubs for advanced die-casting technology.

My company, EMP Tech, serves clients from Germany, Italy, Canada, and the United States, but our manufacturing base gives us a front-row seat to the boom in Asia. The speed of EV development in China is incredible, and it’s creating huge opportunities for suppliers who can keep up. The local supply chain7 is mature, and the level of investment in new technologies like giga-presses is massive. At the same time, we see a clear trend in North America. Our customers there are trying to build more resilient supply chains by sourcing more parts locally or from nearby countries like Mexico. They want to reduce their dependence on long sea freight routes. This means there is growing demand for high-quality, IATF 169498-certified die-casters in both regions. For a global procurement director, understanding the strengths of each region is key to building a flexible and reliable supply chain strategy for the future.

Conclusion

In summary, lightweighting with aluminum is no longer just a trend, but a core strategy. Advances in technology, sustainability demands, and the EV revolution are all pushing it forward.

-

Learn about the latest advancements in high-pressure die casting technologies and their impact. ↩

-

Understand the unique requirements and components that make electric vehicles efficient. ↩

-

Find strategies for reducing carbon footprints in manufacturing, especially in automotive. ↩

-

Discover how giga-casting is revolutionizing the production of electric vehicle components. ↩

-

Explore how aluminum die-casting enhances efficiency and performance in automotive parts. ↩

-

Learn how topology optimization enhances part design for weight reduction and performance. ↩

-

Explore how advancements in technology are reshaping the automotive supply chain. ↩

-

Learn about the significance of IATF 16949 certification for quality in automotive manufacturing. ↩