Struggling with unclear die casting quotes? Hidden costs can derail your project budget. Let’s break down every factor to ensure you get a clear and fair price.

The price of an aluminum die casting part1 is set by a combination of key factors. These include the cost of the raw aluminum alloy2, the complexity and size of the mold3, the total production volume4, and the specific casting and finishing processes5 required.

This gives you the basic framework. However, to truly manage your budget and partner effectively with your supplier, you need to understand the details behind each cost. In my 20 years in this industry, I’ve seen that the best project outcomes happen when customers understand these pricing levers. Let’s dive deeper into each one.

What Factors Determine the Price of Aluminum Die Casting?

Feeling overwhelmed by a complex quote? It is hard to compare suppliers when you don’t know exactly what you are paying for. Let’s clarify the main cost drivers.

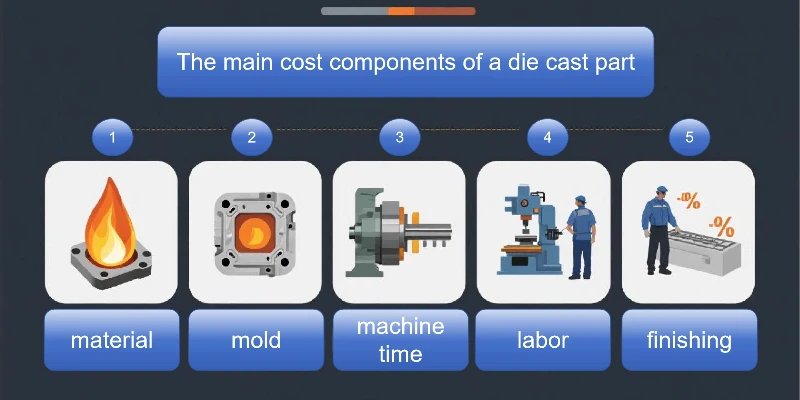

The final price is built on several core elements. The main ones are material cost, tooling (mold) investment, chosen casting process, required production volume, and any secondary operations6 like machining or finishing7.

Each of these factors is connected. A change in one area often affects another. For instance, investing more in a complex mold upfront can reduce the need for expensive machining later. I remember a project for an EV motor housing where the initial mold quote seemed high. But we showed the customer how integrated cooling channels and precision features in the mold would eliminate three separate machining steps. This upfront investment saved them significant money over the production lifecycle. Understanding this balance is key to making smart decisions.

Core Cost Components

| Category | Description | Impact on Unit Price |

|---|---|---|

| Raw Material | Cost of the specific aluminum alloy (e.g., A380, AlSi10Mg). | High |

| Tooling | One-time cost to design and build the die casting mold. | Amortized |

| Production | Machine cycle time, labor, and energy consumption. | Medium |

| Secondary Ops | Machining, surface treatment8, assembly, and testing. | Variable |

Ultimately, a good supplier will provide a transparent quote that breaks down these costs, helping you see where your money is going.

How Do Material Costs Influence Overall Casting Expenses?

Wondering why your quotes fluctuate? Raw material prices are not static and directly impact your final cost. Let’s see how this works and how you can manage it.

Material cost is a large part of the unit price. It is based on the market price of the chosen aluminum alloy, like A380 or a specific ADC12 variant. Price changes in the global aluminum market directly affect part costs.

The specific alloy you need is a major cost driver. Standard alloys like A380 are common and generally more affordable. However, many new energy vehicle components, such as inverter housings or battery enclosures, require alloys with higher thermal conductivity or better ductility, like AlSi10Mg. These high-performance alloys9 cost more.

Alloy Selection and Market Impact

The price isn’t just about the alloy itself. It also includes the cost of melting and handling, as well as managing recycled material. We always factor in a certain percentage of scrap and remelt, which is a standard part of the process.

Managing Price Volatility

Because aluminum is a commodity traded on the London Metal Exchange (LME), its price can change daily. To manage this, many contracts include a price adjustment clause10 tied to the LME index. This creates a fair system where the price adjusts up or down based on real market conditions. I always advise my clients to discuss this openly so there are no surprises down the road.

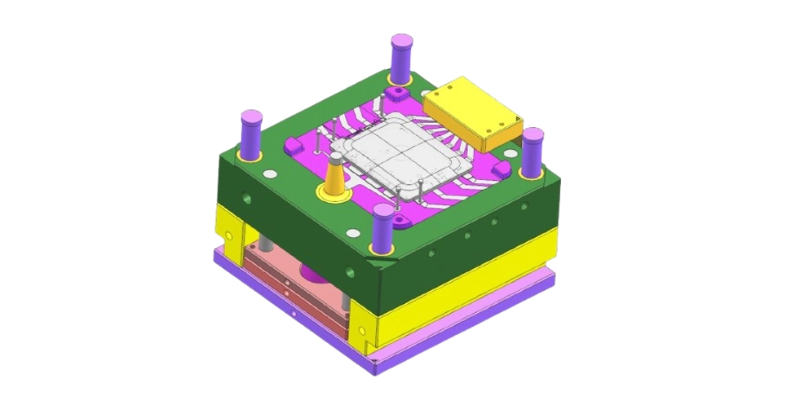

Why Does Mold Design Complexity Affect Unit Price?

Is a high tooling cost a red flag? Not always. A more complex mold can be a smart investment. Let’s explore the connection between mold design and the final unit price.

A complex mold with features like slides, lifters, or intricate cooling systems costs more to build. This higher initial investment is amortized over the production run, slightly increasing the unit price.

The tooling is often the single largest upfront expense in a die casting project. A simple, open-and-shut mold is the cheapest to make. But most parts today are not that simple.

Cost-Driving Mold Features

Features that add complexity and cost include:

- Slides and Lifters: These are moving parts within the mold used to create undercuts or complex internal features. They are essential for parts like housings with connector ports.

- Number of Cavities: A multi-cavity mold produces more parts per cycle, which lowers the unit price but increases the initial tooling cost significantly.

- Mold Material and Coatings: High-strength tool steels like H13 are standard. Special coatings can extend mold life but add to the cost.

I once worked on a structural component for an automotive client. We proposed a more complex mold design that integrated several features previously created by welding. The tooling cost was 20% higher, but it eliminated an entire assembly step, reduced weight, and improved the part’s structural integrity. This is the kind of trade-off we help customers evaluate.

How Does Production Volume Impact Aluminum Die Casting Costs?

Thinking about your order size? Whether you need a few thousand parts or a few million, the production volume is a critical factor in determining your unit price.

Higher production volumes lead to a lower unit cost. The large, one-time investment in tooling is spread across more parts, and manufacturing efficiencies are gained through automation and continuous runs.

This is a classic economy-of-scale principle. Let’s break down how volume affects different costs.

Tooling Amortization

The biggest impact is on tooling amortization. Imagine a mold costs $80,000 to build.

- For a run of 10,000 parts, the amortized tool cost is $8.00 per part.

- For a run of 200,000 parts, the amortized tool cost drops to just $0.40 per part.

This is why die casting is so well-suited for high-volume production.

Operational Efficiency

High volumes also allow us to optimize the manufacturing process. For a large, continuous run, we can dedicate a machine, fine-tune the process parameters for maximum speed and minimum defects, and use automation like robotic extraction and trimming. This reduces labor costs and cycle time, further lowering the price per piece. For smaller runs, the setup time and initial trial-and-error process represent a larger portion of the total cost, making the unit price higher. When you request a quote, providing an accurate Estimated Annual Usage (EAU) is crucial for us to give you the best possible price.

What Is the Cost Difference Between High-Pressure and Low-Pressure Die Casting?

Choosing the right process is key. The costs and benefits of high-pressure die casting11 (HPDC) and low-pressure die casting12 (LPDC) are very different and depend on your part’s needs.

High-pressure die casting (HPDC) generally has a lower unit price for high volumes due to fast cycles, but it requires a higher tooling investment13. Low-pressure die casting (LPDC) has slower cycles but offers better mechanical properties.

The choice between HPDC and LPDC is a technical decision with major cost implications. As an engineer, I guide customers to the right choice based on their part’s specific requirements.

Process Characteristics and Cost

| Feature | High-Pressure Die Casting (HPDC) | Low-Pressure Die Casting (LPDC) |

|---|---|---|

| Cycle Time | Very fast (seconds to minutes) | Slower (minutes) |

| Unit Price | Lower for high volumes | Higher for high volumes |

| Tooling Cost | High | Moderate |

| Part Quality | Good surface finish, thinner walls | Excellent mechanical properties, less porosity |

| Best For | Housings, covers, complex shapes | Wheels, structural parts, high-integrity parts |

HPDC is the workhorse of the industry, ideal for parts like motor controllers or communication device housings. The speed is unmatched. LPDC is a more specialized process. We use it for parts that require high strength and pressure tightness, like certain types of high-performance suspension components or leak-proof chambers. The slower, more controlled filling process results in a denser, stronger part but takes more machine time, which increases the unit cost.

How Do Secondary Operations and Surface Finishing Affect Pricing?

Is the casting itself the final step? Rarely. Most components require additional work after they come out of the mold, and these steps add to the final cost.

Secondary operations like CNC machining14, trimming, deburring, and various surface finishes are priced separately. Each additional step adds labor, machine time, and material costs to the final part price.

After a part is cast, it’s often not ready for use. It needs finishing to meet the final specifications. I always tell my clients to think of the "price per finished part," not just the "price per casting."

Common Post-Casting Processes

- Trimming and Deburring: Every casting has a gate and overflow that must be removed. This can be done with a trim press (for high volumes) or by hand (for lower volumes or complex parts).

- CNC Machining: This is used to create features that cannot be cast, such as threaded holes, O-ring grooves, or extremely precise mating surfaces. The cost depends on machine time and complexity.

- Surface Finishing: This is done for cosmetic or protective reasons. Common options include shot blasting (for a uniform matte finish), powder coating (for color and durability), or anodizing (for corrosion resistance).

For EV parts requiring high airtightness, we often perform impregnation—a process that seals any microporosity—followed by a pressure leak test. Each of these steps is a line item on the final quote, and understanding their necessity is key to controlling costs.

Why Does Tolerance Requirement Play a Role in Final Cost?

How precise does your part need to be? The tighter the tolerances you specify on your drawing, the more it can cost to produce the part reliably and consistently.

Tighter tolerances often require more robust molds, slower production cycles for better stability, and more intensive quality control, including CMM inspection. These additional measures increase the overall manufacturing cost.

In die casting, we can achieve very good "as-cast" tolerances. However, pushing beyond standard limits has cost implications across the entire process.

How Tolerances Drive Costs

- Tooling: To hold tight tolerances, the mold must be built to an even higher level of precision. This means more precise machining of the tool steel and potentially using higher-grade materials, increasing the mold cost.

- Production Process: We may need to run the machine at a slower, more controlled cycle to minimize thermal variation and maintain consistency. This reduces output and increases the cost per part.

- Quality Control: Verifying tight tolerances requires more than just visual checks or basic gauges. It often demands programming and running parts on a Coordinate Measuring Machine (CMM). This inspection time adds to the cost.

I always work with customers during the DFM phase to review their tolerances. We identify which ones are truly critical for function and which can be relaxed without affecting performance. This simple exercise can lead to significant cost savings without compromising the part’s quality.

How Can Suppliers Optimize Costs Without Compromising Quality?

Want a lower price without sacrificing performance? The best way to optimize costs is through smart design and early collaboration with your supplier. It is about working smarter, not cheaper.

Cost optimization is achieved through Design for Manufacturability15 (DFM) analysis, selecting the most cost-effective alloy that meets specs, and designing a tool that balances upfront cost with long-term production efficiency.

Cutting costs should never mean cutting corners. At EMP Tech, our approach to cost optimization16 is built on engineering expertise and partnership.

Strategies for Smart Savings

- Early Supplier Involvement (ESI): The biggest opportunity for cost savings is at the very beginning of a project. By getting involved in the design phase, we can provide DFM feedback to simplify the part, reduce weight, and minimize the need for secondary operations6.

- Mold Flow Simulation: Before we cut any steel, we run simulations to predict how the metal will flow into the mold. T

-

Understanding these factors can help you negotiate better pricing and manage your budget effectively. ↩

-

Explore how different alloys impact costs and performance in die casting. ↩

-

Learn how mold design can influence your overall project budget. ↩

-

Discover the economy of scale and how it can lower your unit costs. ↩

-

Understanding these processes can help you choose the best options for your project. ↩

-

Explore how additional processes can add to your final costs. ↩ ↩

-

Explore how these processes contribute to the final quality and cost. ↩

-

Learn about finishing options that can improve durability and aesthetics. ↩

-

Discover the benefits and costs associated with using advanced alloys. ↩

-

Discover how this clause can protect you from market volatility. ↩

-

Explore why HPDC is often preferred for high-volume production. ↩

-

Learn about LPDC’s benefits for specific applications requiring high integrity. ↩

-

Learn about the upfront costs and how they affect your overall budget. ↩

-

Find out how precision machining can enhance your part’s quality and cost. ↩

-

Learn how DFM can optimize costs and improve part quality. ↩

-

Learn effective methods to reduce costs without compromising quality. ↩