Are you struggling with suppliers who cannot meet the demanding specs for your automotive parts? Unreliable components lead to production delays, budget overruns, and compromise your final product’s quality.

Reliable aluminum die casting solutions come from a partner who combines engineering expertise, robust IATF 16949 quality systems, and advanced technology. This ensures every component, from prototype to mass production, meets the strictest automotive standards for performance and efficiency.

In my two decades in this industry, I’ve seen it all. I’ve seen projects get derailed by suppliers who treat die casting like a simple commodity. The reality is, for the demanding world of automotive and especially electric vehicles, it is a complex engineering science. A purchasing director I work with from a major German Tier 1 once told me, "I don’t just buy parts; I buy certainty." That has stuck with me. My mission, and the mission of my team at EMP Tech, is to provide that certainty. We act as an innovation partner, not just a parts maker, to ensure your project succeeds.

How do you master die casting for demanding applications?

Are your most challenging parts failing in the field? For complex components with thin walls or high-pressure requirements, a standard casting approach is a recipe for failure and costly recalls.

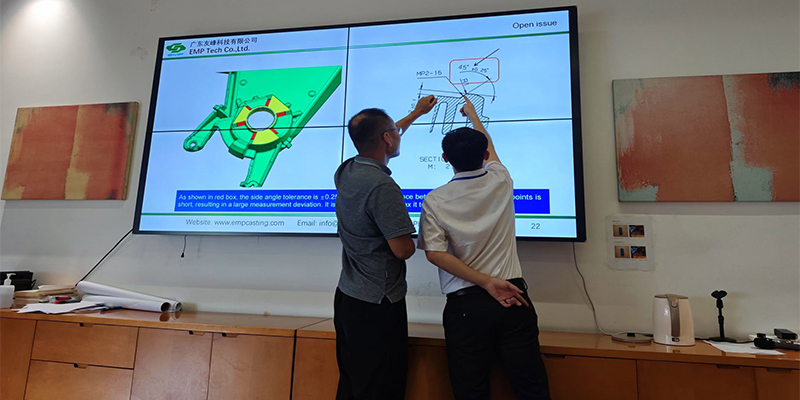

Mastery comes from a deep understanding of metallurgy, advanced simulation, and precise process control. It means using tools like mold flow analysis to perfect the design before production and monitoring every machine parameter in real time.

We recently worked on a hydraulic valve body for a North American client. The design had incredibly complex internal channels and required absolute pressure tightness. A previous supplier had failed, delivering parts with high rates of internal porosity1. Our approach was different. We started with a comprehensive Design for Manufacturability (DFM)2 and mold flow analysis3. The simulation showed us exactly where air would get trapped during injection. Based on this data, we optimized the gate locations and added vents and vacuum assistance to the die. By solving the problem digitally first, we ensured the physical tool was right from the first shot. This proactive, science-based approach is what separates basic casting from true mastery. It’s how we deliver components that perform flawlessly under the most extreme conditions.

How does precision die casting drive automotive performance?

Are minor inaccuracies in your components causing major headaches on your assembly line? Poorly fitting parts can lead to vibrations, premature wear, and efficiency losses in the final vehicle.

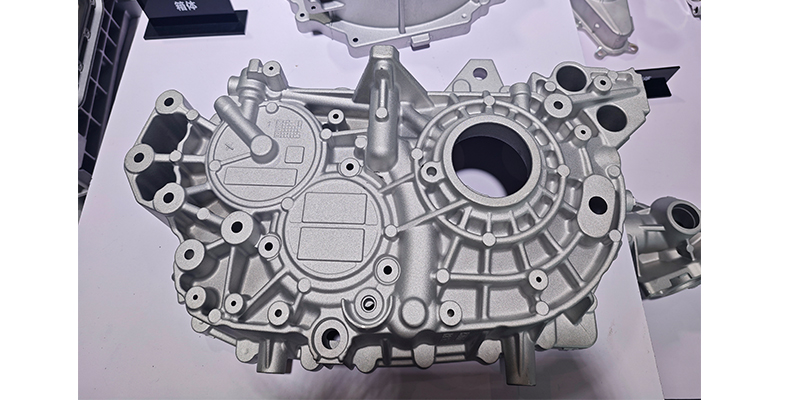

Precision die casting creates components with extremely tight tolerances, often supplemented by CNC machining. This ensures a perfect fit for critical parts like motor housings and transmission cases, leading to quieter operation, reduced friction, and improved overall vehicle performance.

I remember a project involving a motor end cap for an electric motor. The tolerance for the bearing seat was just a few microns. Any deviation would cause the motor’s rotor to be misaligned, leading to noise and eventual bearing failure. Our process combines the speed of die casting with the precision of CNC machining4. The casting gets us 95% of the way there, creating a strong, lightweight, and near-net-shape part. Then, our 5-axis CNC machining centers finish the critical features, like the bearing pocket and mounting faces, to the exact specification. We verify every dimension with our CMM machines. This combination of technologies is how we guarantee that thousands of parts are not just similar, but truly identical. This level of precision is non-negotiable for building high-performance, efficient, and reliable vehicles.

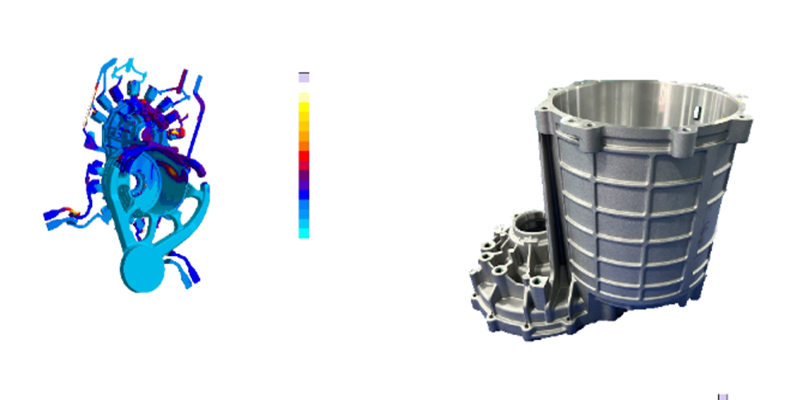

What makes die casting essential for high-quality EV components?

Is your EV project struggling to balance weight, strength, and thermal management? The unique demands of electric vehicles require a manufacturing solution that can do it all without compromise.

Die casting is essential for EVs because it produces lightweight, structurally rigid components with complex features. It allows for the integration of cooling channels and electronics housing, which are critical for battery enclosures, inverter casings, and motor housings.

The shift to electric vehicles has been the biggest driver of innovation in my career. My team has been deeply involved in developing housings for OBCs (On-Board Chargers), inverters, and large battery trays. These aren’t simple boxes. A battery enclosure, for example, has to be incredibly strong to protect the cells in a crash, sealed to protect from the elements, and have integrated channels to manage heat. Creating this from stamped steel would mean dozens of individual pieces welded together, adding weight and potential points of failure. With high-pressure die casting5, we can create it as a single, complex, and lightweight piece. This part consolidation simplifies our customer’s supply chain and assembly process6, reduces weight to increase range, and improves the overall safety and reliability of the vehicle.

What innovations in pressure die casting ensure quality and consistency?

Are you getting inconsistent quality from one batch of parts to the next? This process variability can disrupt your production schedule and force you to implement costly incoming inspection routines.

Modern innovations like real-time process monitoring, vacuum-assisted casting, and advanced alloy development are key. These technologies reduce defects like porosity and ensure that the millionth part produced is identical in quality to the first.

Technology is what allows us to guarantee consistency. Every one of our die casting machines is equipped with sensors that monitor dozens of parameters on every single shot—pressure, velocity, temperature, and more. This data is tracked in real-time. If any parameter drifts outside our predefined control limits, the system immediately alerts our process engineer. This prevents defects from ever happening. For parts that require the highest integrity, like those for safety systems or high-pressure applications, we use vacuum-assisted die casting. This process sucks the air out of the die cavity right before we inject the metal, which practically eliminates gas porosity. These innovations are not just fancy add-ons; they are fundamental tools we use to build quality and consistency directly into the manufacturing process from the very start.

How do you go from a custom prototype to high-volume production?

Is your team worried that a successful prototype won’t be manufacturable at scale? The transition from a single perfect part to thousands of them is where many projects fail.

A successful transition requires a partner with a structured process. This involves DFM analysis on the prototype, building robust production tooling, and using automated casting and quality systems to maintain perfect consistency at high volumes.

We guide our clients through this journey every day. It starts with the prototype, but we are always thinking about mass production. Even at the earliest stages, our DFM analysis focuses on creating a design that is not just functional but also efficient to cast in high volumes. After the design is locked, we follow the rigorous Automotive Industry Action Group (AIAG) guidelines for launching a new product, including the Production Part Approval Process (PPAP)7. We build hardened steel production tools designed for millions of cycles. Our production cells are automated with robots for extraction, quenching, and trimming to ensure every part is handled the same way, every time. This structured, forward-thinking approach removes the risks from scaling up and provides our clients with a smooth and predictable launch from the first prototype to full-scale production.

Conclusion

A reliable die casting partner turns manufacturing challenges into competitive advantages. They deliver precision, innovation, and scalability, ensuring your automotive and EV components perform flawlessly from day one.

-

Discover the causes of internal porosity in die casting and effective methods to prevent it. ↩

-

Explore the concept of DFM and its importance in ensuring efficient and cost-effective die casting processes. ↩

-

Find out how mold flow analysis optimizes die casting designs and prevents defects in automotive parts. ↩

-

Discover the role of CNC machining in achieving high precision and quality in die-cast automotive parts. ↩

-

Explore the benefits of high-pressure die casting in producing complex and lightweight automotive components. ↩

-

Discover how die casting can streamline supply chains and improve assembly efficiency in automotive manufacturing. ↩

-

Understand the significance of PPAP in ensuring quality and compliance in automotive part production. ↩