Your components need to be stronger and lighter, but standard alloys can’t meet the specs. This puts your project timeline and budget at risk of failure.

AlSi10MgFe is a versatile aluminum alloy known for its excellent castability, good mechanical strength, and corrosion resistance. Its specific composition, particularly the balance of silicon, magnesium, and controlled iron, makes it ideal for producing complex, lightweight, and durable automotive components.

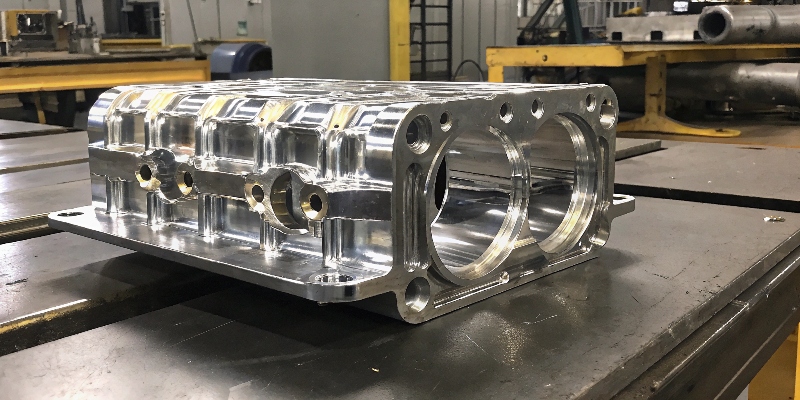

When a Tier 1 supplier comes to me with a new EV project, like an inverter housing or a structural battery case, the conversation almost always turns to material selection. The pressures are immense: make it lighter, make it stronger, and make it handle heat, all while keeping costs in check. For years, my answer has consistently pointed towards one family of alloys, with AlSi10MgFe1 often being the top contender. It’s not just about what’s on the datasheet; it’s about how the alloy behaves in the real world of high-pressure die casting. Understanding what each element in its name does is the first step to unlocking its full potential for your project.

What Are the Key Elements in AlSi10MgFe and What Do They Do?

You see a material spec sheet filled with chemical symbols, but they don’t mean much in practice. This uncertainty makes it hard to justify your alloy choice or troubleshoot quality issues.

The main elements are aluminum, silicon 2 (~10%) for fluidity, and magnesium for strength. Iron is intentionally controlled to prevent brittleness. Each element plays a critical role in defining the alloy’s final performance and castability.

Think of an alloy’s composition as a recipe. Each ingredient has a specific job, and the final result depends on getting the proportions right. In AlSi10MgFe, we are balancing castability with mechanical performance.

| Element | Typical % (by weight) | Primary Function |

|---|---|---|

| Silicon (Si) | 9.0 – 11.0 | Improves fluidity, reduces shrinkage, lowers melting point. |

| Magnesium (Mg) | 0.2 – 0.45 | Enables strengthening through heat treatment (T5/T6). |

| Iron (Fe) | < 0.55 (Controlled) | Prevents die soldering, but excess causes brittleness. |

| Manganese (Mn) | < 0.45 | Counteracts the negative effects of iron. |

| Aluminum (Al) | Balance | The base metal of the alloy. |

The Role of Each Element

Silicon (Si) is the most important element for die casting. With around 10% silicon, the alloy becomes very fluid when molten. This means it can easily fill complex molds with thin walls before it solidifies, which is perfect for intricate parts like heat sink fins on an OBC housing.

Magnesium (Mg) is what gives this alloy its strength. Even a small amount allows the material to be heat-treated. A simple T5 aging process can significantly increase the tensile strength and hardness, making the component much more durable without adding weight.

Iron (Fe) is a necessary evil. We need a small amount to act as a release agent, preventing the molten aluminum from chemically welding itself to our expensive steel molds. However, too much iron forms sharp, needle-like structures in the metal that act like tiny internal cracks, making the part brittle. We carefully control iron content to get the benefit without the drawback.

How Do Its Mechanical and Thermal Properties Benefit Your Parts?

You need parts that can withstand mechanical stress and operational heat without failing. Choosing an alloy based only on a datasheet can be risky if you don’t understand the real-world performance.

AlSi10MgFe offers a great combination of tensile strength3, hardness, and thermal conductivity4. It maintains its properties at moderately elevated temperatures, making it suitable for components near engines or power electronics.

The raw numbers on a spec sheet only tell half the story. The real benefit comes from how these properties translate into a reliable, high-performance component. For automotive parts, especially in EVs, the combination of strength, weight, and thermal management is everything. I often work with SQEs who need to guarantee performance, and this alloy gives them a lot of confidence. Its properties can be tailored through heat treatment, which is a major advantage.

| Property | As-Cast (F) | Heat-Treated (T5) | Unit |

|---|---|---|---|

| Ultimate Tensile Strength | ~240 | ~290 | MPa |

| Yield Strength | ~120 | ~220 | MPa |

| Elongation | ~3% | ~2% | % |

| Hardness | ~75 | ~95 | HBW |

| Thermal Conductivity | ~130 | ~140 | W/m·K |

Performance in Application

The significant jump in yield strength after a T5 heat treatment is critical. It means the part can handle much higher loads before it permanently deforms. For a structural component, this is non-negotiable. Its good thermal conductivity is also a key feature for EV applications. We make motor controller housings from this alloy precisely because it can efficiently draw heat away from the sensitive electronics inside, ensuring the system runs reliably. The material’s stability at elevated temperatures means it won’t lose its strength when the vehicle is working hard.

Where is AlSi10MgFe Commonly Used in Automotive and EV Components?

You’re designing a new component and need to choose a proven, reliable material. Specifying an uncommon alloy can introduce supply chain risks5 and manufacturing headaches you want to avoid.

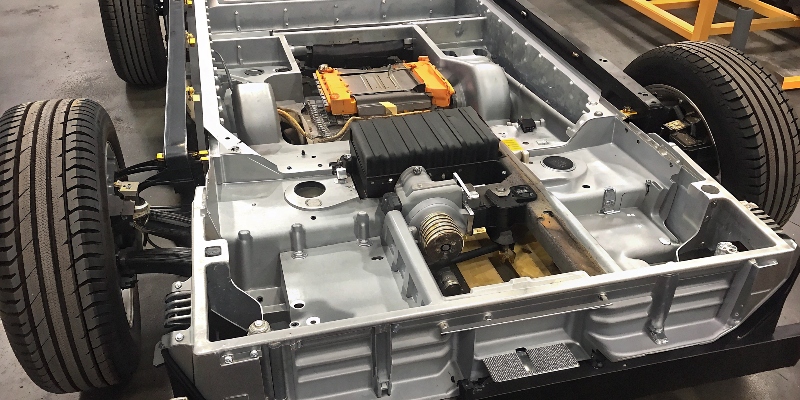

This alloy is a workhorse for complex, load-bearing parts. It is widely used for engine blocks and transmission cases, and in EVs, it’s perfect for motor housings, inverter enclosures, and battery trays.

This isn’t a niche, experimental alloy; it’s a globally recognized standard for high-performance die casting. My team and I have developed dozens of parts using AlSi10MgFe for Tier 1 suppliers in Germany, the US, and Canada. Its versatility makes it a safe and reliable choice for a wide range of demanding applications.

Electric Vehicle (EV) Housings

This is where the alloy truly shines today. I remember working on a motor controller housing for a German client. They needed excellent heat dissipation, high strength for mounting points, and complex internal features for electronics. AlSi10MgFe was the obvious choice. We used a T5 heat treatment to give it the necessary strength while keeping the process cost-effective and minimizing distortion. It’s the go-to material for:

- Motor housings

- Inverter and converter enclosures

- On-Board Charger (OBC) housings

- Battery pack enclosures and trays

Powertrain and Chassis Components

Before the EV boom, AlSi10MgFe was already proven in traditional automotive applications that required a step up from standard alloys. Its balance of strength, pressure tightness, and castability made it ideal for:

- Transmission and clutch housings

- Oil pans

- Engine mounting brackets

- Steering gear housings

The common thread is complexity and performance. If a part has thin walls, needs to be leak-proof, and has to carry a load, this alloy is on the short list.

What Are Its Advantages Over Standard Al-Si Alloys?

You are trying to reduce costs or simplify your supply chain, but switching to a cheaper, standard alloy like A380 seems risky. You need to understand the trade-offs to make an informed decision.

Its main advantages are a superior strength-to-weight ratio (especially after heat treatment) and better properties at elevated temperatures. This allows for lighter designs that can handle more demanding operational loads.

Comparing AlSi10MgFe with a more common alloy like A380 (also known as ADC10) is a frequent exercise. While A380 is a good general-purpose alloy, it has limitations that AlSi10MgFe overcomes, which often justifies the choice for high-performance applications.

| Feature | AlSi10MgFe | A380 (AlSi8Cu3Fe) | Why it Matters |

|---|---|---|---|

| Heat Treatable | Yes (T5, T6) | Not effectively | Can significantly increase strength and hardness. |

| Ductility | Moderate (~3%) | Lower (~2.5%) | Better resistance to fracture under load. |

| Fluidity | Excellent | Very Good | Ideal for filling complex, thin-walled designs. |

| Corrosion Resistance | Good | Fair | Lower copper content improves durability. |

| Pressure Tightness | Excellent | Good | Better for leak-proof housings. |

The ability to heat treat is the single biggest advantage. It allows a designer to create a part that is relatively easy to cast but can be made much stronger afterward. This means you can design lighter parts with thinner walls that still meet strength requirements. The lower copper content in AlSi10MgFe also gives it better corrosion resistance, which is important for parts exposed to the elements. For any housing that needs to be perfectly sealed, the finer microstructure and excellent fluidity of AlSi10MgFe lead to lower porosity and superior pressure tightness compared to A380.

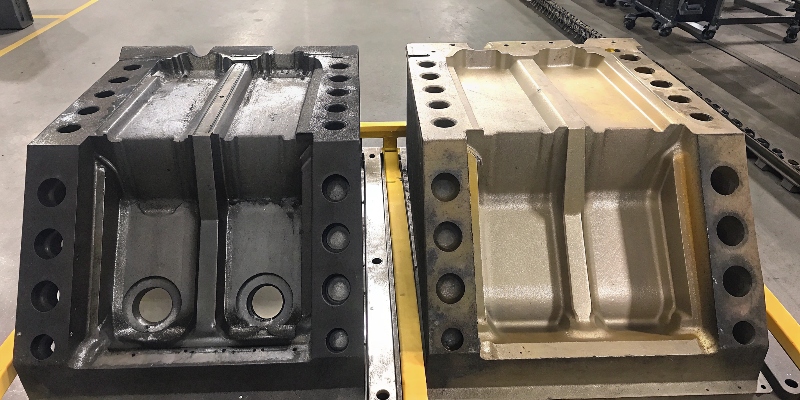

What Do You Need to Consider When Optimizing the Casting Process?

You’ve selected the right alloy, but your parts are still failing quality checks for porosity or cracks. The issue might not be the material itself, but how you are processing it.

Key considerations include precise temperature control of both the metal and the mold, optimized injection parameters to minimize turbulence, and careful planning for heat treatment to avoid distortion.

Using a great alloy is just the start. To get a good part, you have to respect the material’s characteristics in your process. AlSi10MgFe is very capable, but it’s not forgiving of sloppy process control. This is where deep technical experience makes all the difference.

Process Control is Everything

- Temperature Control: This alloy flows beautifully, but you must keep the die at a stable, elevated temperature (typically 220-280°C). If the die is too cold, you’ll get cold shuts where the metal fails to fuse. If the molten metal is too hot, you risk increased gas absorption and die soldering.

- Injection and Vacuum: Because it flows so well, it’s very sensitive to air entrapment. We almost always pair this alloy with a vacuum-assisted die casting process. By pulling air out of the mold cavity just before injection, we can produce incredibly dense, low-porosity parts that are perfect for applications requiring high airtightness.

- Heat Treatment Strategy: Planning for heat treatment starts at the design stage. A T6 treatment (solutionize, quench, age) gives the absolute maximum strength, but the rapid cooling of the quench can warp thin-walled parts. For many housings, a simpler T5 treatment (artificially aged from the as-cast state) provides an excellent boost in strength with much lower risk of distortion and lower cost. We help customers make this trade-off every day.

Conclusion

AlSi10MgFe is a top choice for high-performance die castings. Its balanced properties offer the strength, lightweight potential, and castability needed for modern automotive, and especially EV, components.

-

Explore how AlSi10MgFe enhances strength and reduces weight in automotive applications. ↩

-

Explore the critical function of silicon in enhancing fluidity and reducing shrinkage. ↩

-

Understand the importance of tensile strength in ensuring the reliability of automotive components. ↩

-

Discover how thermal conductivity affects the performance of automotive parts under heat. ↩

-

Learn about the implications of material choices on supply chain stability. ↩