An ungrounded motor housing in an EV is a ticking time bomb. It creates hidden electrical dangers that can lead to catastrophic failures, putting both people and expensive components at risk.

Failing to ground an aluminum electric motor housing creates severe safety risks, including electric shock, short circuits, and fires. It also causes electromagnetic interference (EMI) that disrupts vehicle electronics and can damage the motor controller, ultimately failing to meet critical safety standards like ISO 6469.

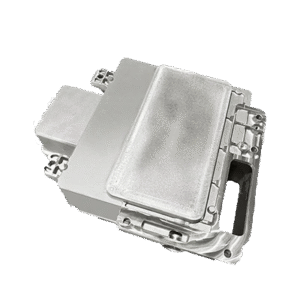

In my 20 years in die casting, I have seen how small details can have huge consequences. A proper ground connection1 is one of the most critical. It’s a simple step, but skipping it can undermine the entire safety and reliability of an electric vehicle. Let’s look at the specific dangers one by one, so you can understand why my team and I never compromise on this.

How can ungrounded housings create electrical shock hazards for operators and staff?

Your team works around high-voltage systems2 every day. A single ungrounded part can turn a routine maintenance check into a life-threatening situation. Proper grounding is their most basic protection.

If an internal high-voltage wire accidentally touches an ungrounded housing, the entire metal surface becomes live. Anyone touching it provides a path for the current to go to the ground, causing a severe or fatal electric shock. Grounding prevents this by creating a safe, low-resistance path.

Modern electric vehicles operate at 400 volts, 800 volts, or even higher. At these levels, any electrical fault is incredibly dangerous. The aluminum housing is an excellent conductor of electricity. This is a problem when things go wrong inside the motor.

The Housing Becomes a Live Conductor

Imagine a wire inside the motor where the insulation has worn away. If that wire touches the inside wall of the ungrounded motor housing, the entire casing instantly becomes energized to 400 or 800 volts. It gives no warning. A technician on the assembly line or a mechanic in a workshop who touches it will complete the circuit with their body. The result is a severe electric shock3. I have always stressed to my team that every conductive part must be treated as potentially live until it is proven to be safely grounded.

How Grounding Creates a Safe Path

A correctly grounded housing completely changes this situation. The ground wire provides a very low-resistance path from the housing directly to the vehicle’s chassis ground. If that same faulty wire touches the housing, the electricity takes the easy way out through the ground strap4, not through a person. This massive surge of current, a short circuit, will immediately trip the vehicle’s circuit breakers5 or blow a fuse. The system shuts down safely in milliseconds.

| Scenario | Ungrounded Housing | Grounded Housing |

|---|---|---|

| Fault Current Path | Through a person touching the housing | Through the ground wire to the chassis |

| Outcome for Person | Severe electric shock or death | Safe, no shock |

| Outcome for System | Remains dangerously live | Circuit breaker trips, system powers down |

Does an ungrounded housing increase the risk of short circuits?

A short circuit in an EV’s high-voltage system is a catastrophic failure. It can destroy expensive parts and even cause fires. Grounding the motor housing is a simple, critical step to prevent this.

Yes, it greatly increases the risk. Without a ground path, fault current from the housing may travel through unintended paths, like sensor wires or other components. This can create a direct short between high-voltage circuits, causing extreme heat, arcing, and potential battery fires.

A short circuit is electricity taking a shortcut it was never meant to take. In a high-voltage system, this shortcut releases a massive amount of energy very quickly. The motor housing plays a key role in controlling where this energy goes during a fault.

The Role of the Chassis Ground

The entire metal chassis of the vehicle serves as a common ground point. Every component’s electrical system is referenced to it. By securely connecting the motor housing to the chassis, you make it part of this unified ground plane. If a fault occurs, the current has a clear and predictable path back to the battery, which allows safety systems to react instantly. An ungrounded, or "floating," housing is an electrical island. When it becomes live, the electricity will try to jump to any nearby grounded conductor to complete its circuit. This could be a data cable, a cooling line, or another component’s housing.

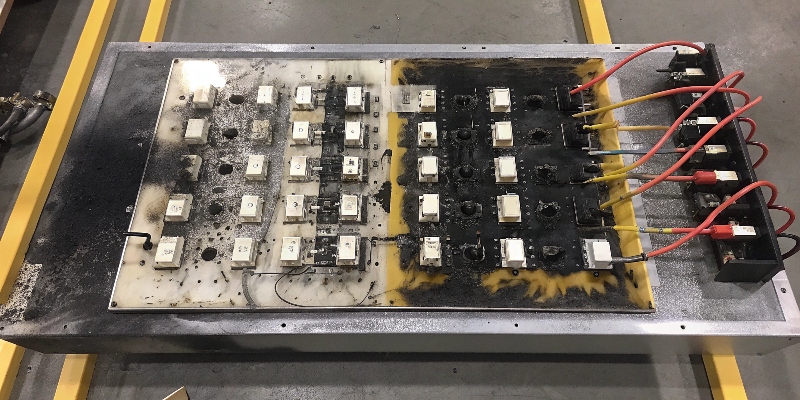

Preventing Catastrophic Failures

I was once involved in a project where a supplier failed to ensure a solid ground connection. During validation testing, a minor internal wire fault caused the live housing to arc to a nearby low-voltage sensor harness. The high-voltage current surged through the sensor system and destroyed the entire motor controller6 unit. The damage was in the tens of thousands of dollars. The root cause was a single, overlooked ground strap. A proper ground connection would have contained the fault and tripped a breaker, costing almost nothing.

Can poor grounding cause electromagnetic interference (EMI)?

Your vehicle’s electronics are in constant communication. Odd glitches, like a buzzing radio or a flickering screen, can sometimes be traced back to a simple grounding problem. A well-grounded motor housing is a shield.

Yes. The motor and inverter create powerful electromagnetic fields. The aluminum housing is designed to act as a Faraday cage to contain this noise. If the housing is not grounded, this shield is broken, and the interference can disrupt radios, sensors, and other sensitive electronics.

Electric motors and the inverters that control them are very noisy, electrically speaking. The rapid switching of high currents creates a lot of electromagnetic radiation, or noise. This noise can interfere with other electronic systems in the car.

The Housing as a Faraday Cage

An enclosed metal container, like our aluminum motor housing, acts as a Faraday cage7. It blocks electromagnetic fields from getting in or out. For this to work correctly, the cage must be connected to ground. Grounding gives the captured electrical noise a path to dissipate safely. Without a ground connection, the noise builds up on the housing itself, which then acts like an antenna, broadcasting that interference throughout the vehicle. My team and I pay close attention to the design of grounding points in our DFM analysis, ensuring they provide a clean, effective path for EMI.

Symptoms of EMI Problems

The effects of EMI can range from annoying to dangerous. It depends on which systems are affected.

| Source of EMI | Affected System | Symptom |

|---|---|---|

| Motor Switching Noise | AM/FM Radio | Static, buzzing, or poor reception |

| Inverter Harmonics | Infotainment Screen | Flickering or display glitches |

| High-Frequency Noise | ADAS Sensors | False warnings or incorrect readings |

In the worst cases, EMI can interfere with critical safety systems. For example, it could disrupt the signals from wheel speed sensors, affecting the stability control system. Proper grounding is a fundamental part of ensuring the vehicle’s electronic systems can all work together without interfering with each other.

How does an ungrounded housing damage motor controllers and electronics?

The motor controller is the expensive brain of the electric drivetrain. Stray electrical currents and unstable voltages can slowly degrade or instantly destroy it. A solid ground connection is the best insurance you have.

An ungrounded housing creates a "floating ground," leading to unstable voltage references. This can send stray currents and voltage spikes into the motor controller and other electronics, overloading sensitive circuits and causing either immediate failure or long-term, hard-to-diagnose damage.

All electronics are designed to work with a stable ground reference, which should be zero volts. When the motor housing isn’t grounded, its electrical potential can float to unpredictable levels, creating a hazardous environment for connected electronics.

Understanding Floating Grounds

Think of a floating ground like a boat with no anchor in a storm. Its position is unstable and unpredictable. Electrically, this means the voltage on the housing can fluctuate wildly relative to the rest of the car’s systems. The motor controller, which is physically and electrically connected to the motor, expects the housing to be at a stable zero volts. When it’s not, the sensitive logic circuits inside the controller can be exposed to voltages they were never designed to handle. This is a silent killer for power electronics.

The Path of Destructive Currents

I remember a customer who was experiencing random motor controller failures in the field. After weeks of investigation, we found the cause was a painted-over ground boss on the motor housing. The connection was intermittent. Sometimes it worked, sometimes it didn’t. This inconsistency created voltage spikes that were sent back into the controller, eventually burning out its internal components. These kinds of failures are frustrating because they seem random. But they often trace back to a fundamental issue like a poor ground. That is why our process at EMP Tech includes verifying all connection points are bare metal and provide a solid, reliable electrical path.

Why is grounding critical for meeting automotive safety standards like ISO 6469?

Your project must pass strict safety certifications to go to market. Failing a standard like ISO 64698 because of a basic grounding error can cause major project delays and costly redesigns.

Automotive safety standards like ISO 6469 mandate equipotential bonding, which requires all exposed conductive parts of a high-voltage system to be securely grounded. An ungrounded motor housing is an automatic failure during certification because it directly violates this core electrical safety principle.

Safety standards are not just guidelines; they are strict rules that exist to prevent injury and death. In the world of high-voltage electric vehicles, these rules are especially important. Grounding is not just a good idea—it is a requirement.

Key Requirements of ISO 6469

ISO 6469, "Electrically propelled road vehicles — Safety specifications," is a key standard for EVs. One of its fundamental requirements is called equipotential bonding. This simply means that all the metal housings and conductive parts that a person could touch must be connected together electrically and tied to the chassis ground. The goal is to ensure there can be no dangerous voltage difference between any two parts. An ungrounded motor housing directly violates this principle. During a certification test, an inspector would immediately identify the lack of a ground connection as a major non-conformance, and the vehicle would fail.

The Cost of Non-Compliance

Failing a certification test is expensive. It means project delays, redesign work, and re-testing. But the true cost of non-compliance is much higher. It involves legal liability. If an accident involving electric shock ever occurred, and it was discovered that the vehicle did not comply with safety standards, the legal and financial consequences for the manufacturer and its suppliers would be severe. As an engineering partner, my team and I see it as our responsibility to design components that ensure compliance from the very beginning. We build safety into the part, so it’s not something you have to worry about later.

Conclusion

Properly grounding your aluminum motor housing is not optional. It is essential for safety, system reliability, and meeting automotive standards. It is a foundational requirement for any successful EV project.

-

Understanding the importance of grounding can improve safety and reliability. ↩

-

Explore the risks associated with high-voltage systems to enhance safety measures. ↩

-

Learn how grounding can prevent electric shock hazards in high-voltage systems. ↩

-

Understanding ground straps can help ensure proper grounding in EV systems. ↩

-

Discover the role of circuit breakers in enhancing safety in electric vehicles. ↩

-

Learn how grounding impacts the performance and longevity of motor controllers. ↩

-

Understanding this concept can help in designing safer electronic systems. ↩

-

Learn about this critical safety standard and its implications for EV design. ↩