What Automobile Parts Are Manufactured Using Die Casting?

Trying to choose the right manufacturing process for every part in a modern vehicle is a huge challenge. Make the wrong choice, and you end up with components that are too heavy or too expensive.

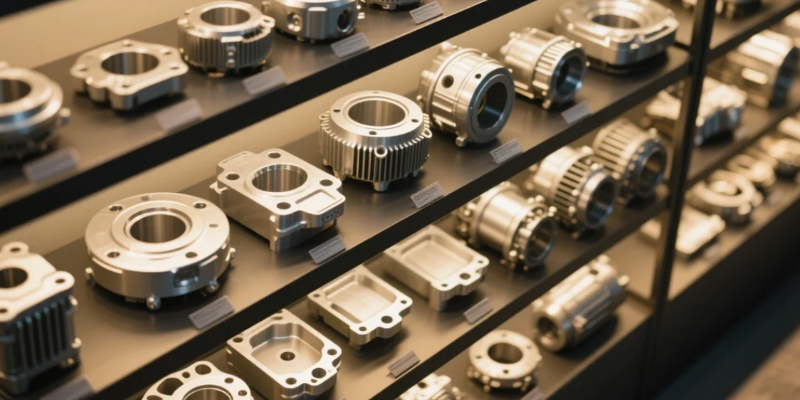

Die casting1 is used to manufacture a wide range of automotive parts2, including powertrain components3 like transmission and motor housings, large structural elements like battery trays4 and shock towers5, and complex electronic enclosures6 for ECUs and ADAS systems7. It excels at producing lightweight, intricate parts.

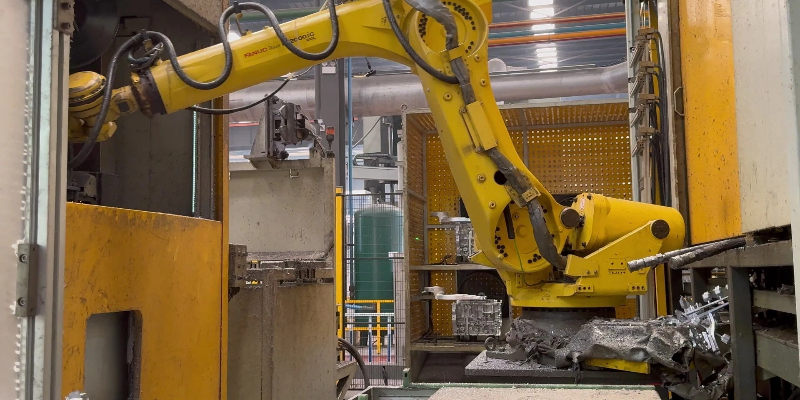

When people think of die casting, they sometimes picture small, simple parts. But in my 20-plus years in this industry, I’ve seen it evolve into a core technology that enables some of the most advanced components in both gasoline and electric vehicles. Its versatility in creating strong, lightweight, and complex parts at scale is why engineers and procurement directors I work with, from Germany to the US, rely on it so heavily. Let’s look at where you’ll find these critical parts and why die casting is the perfect choice for them.

What Are the Most Common Die Cast Parts in Automotive Applications?

It’s easy to think die casting is just for small, simple brackets. This limited view means you might be missing huge opportunities to save weight and integrate functions on major vehicle components.

The most common die cast parts are powertrain housings (engine, transmission, motor), structural components (battery trays, shock towers5), and various enclosures and covers. You’ll find them in the engine bay, chassis, and integrated into the vehicle body, delivering a combination of strength and lightweight performance.

Throughout my career, I’ve seen die casting’s application list grow longer every year. It’s moved from being a go-to for standard components to being an essential enabler of automotive innovation8, especially with the rise of EVs. When a client asks what we can make, I explain that the applications fall into a few key categories.

| Part Category | Examples | Key Benefit |

|---|---|---|

| Powertrain | Transmission Housings, Oil Pans, Motor Housings, Inverter Cases | Complex internal geometry, pressure tightness, heat dissipation |

| Structural | Shock Towers, Cross-Car Beams, Subframes, Battery Trays | High strength-to-weight ratio, part consolidation |

| Electronic Housings | ECU Enclosures, ADAS Sensor Mounts, On-Board Charger (OBC) Housings | EMI shielding9, precision, heat management, complex shapes |

| General Components | Brackets, Steering Components, Valve Covers, Pump Housings | High-volume production speed, low cost per part |

From my first days on the shop floor inspecting oil pans to now leading the development of complex battery trays for new energy vehicles, the common thread is die casting’s ability to solve multiple problems—cost, weight, and complexity—in a single, efficient process.

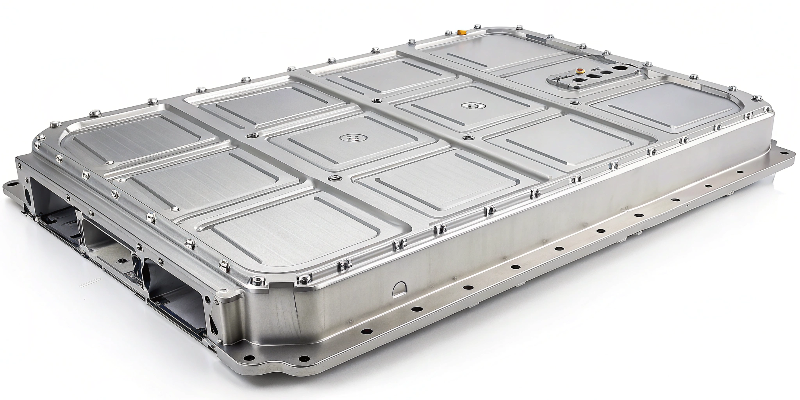

Why Is Aluminum Preferred for EV Structural Components?

EVs need to be lightweight to maximize range but also incredibly strong to protect the battery pack. This creates a difficult design conflict where steel is often too heavy and polymers aren’t strong enough.

Aluminum is preferred for its excellent strength-to-weight ratio, which is crucial for maximizing EV range. Its high thermal conductivity is vital for cooling batteries and power electronics, and its design flexibility allows for the integration of multiple functions into one large casting.

When I talk to procurement directors in the automotive sector, we often discuss total cost and performance, not just the price per kilo. This is where aluminum shines, especially in EV applications. The material choice is strategic. The push for longer range and faster charging has made aluminum the clear winner for large structural components, and it’s for a few very specific reasons.

The first and most obvious reason is lightweighting. Every kilogram we save on the vehicle structure is a kilogram the battery doesn’t have to move, which directly translates to more range. Second is strength and safety. Modern high-strength aluminum alloys, when used in an intelligently designed die casting, can absorb crash energy and provide the rigid protection a battery pack needs. The final, and perhaps most critical, advantage is thermal management10. An aluminum battery tray isn’t just a box; it’s an active part of the cooling system. We can cast in complex channels for liquid cooling that draw heat away from the cells, which is essential for both performance and safety. A single aluminum casting replaces a heavy steel assembly and an independent cooling system—a huge win.

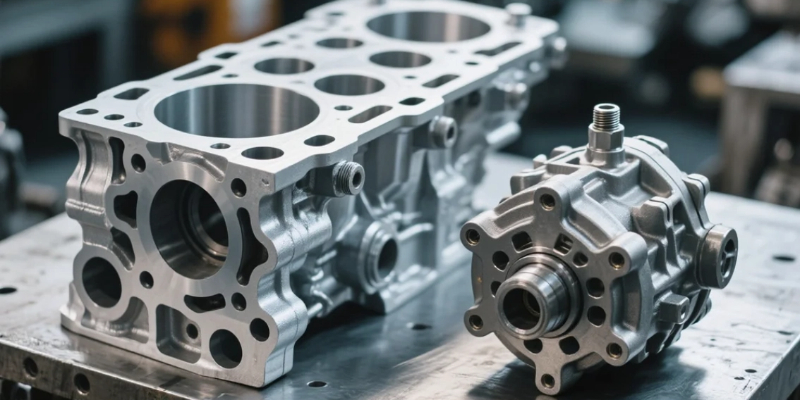

How Is High-Pressure Die Casting Used to Create Such Complex Geometry?

Designers want to integrate features and create sleek, organic shapes to save space and weight. But many traditional manufacturing processes struggle to produce thin walls and intricate internal details consistently.

High-pressure die casting (HPDC) enables complexity by injecting molten metal into a steel die at extremely high speeds and pressures. This forces the metal into every tiny crevice, faithfully reproducing complex features like thin walls, cooling fins, and integrated mounting bosses before it can solidify.

The "magic" of die casting really lies in the physics of the high-pressure process. When a client needs a part with walls just 2mm thick and integrated heat sink fins that are even thinner, HPDC is the only viable process for mass production. I explain it to them in two parts: speed and power.

First, the speed of the injection is incredible, sometimes over 100 miles per hour. This velocity ensures the molten metal can travel to the furthest corners of the mold and fill all the fine details before it starts to cool down and get sluggish. Second, once the mold is full, we apply intense pressure, often over 10,000 PSI. This pressure packs the aluminum molecules tightly together, which minimizes porosity, ensures a crisp surface finish, and perfectly captures all the fine-grained details of the precision-machined steel die. It’s this combination of speed and power that allows us to take a complex 3D model from a computer screen and turn it into a physical part, millions of times, with incredible consistency.

How Is Die Casting Being Used for Autonomous and ADAS Hardware?

Autonomous driving systems rely on a suite of sensitive cameras, LiDAR, and radar units. These sensors need to be mounted with absolute precision and must be protected from vibration and the elements to function safely.

Die casting is used to create the rigid, dimensionally stable mounting brackets and protective housings for ADAS hardware. The process delivers the tight tolerances needed for precise sensor alignment and the EMI shielding and heat dissipation required for the sensitive electronics inside.

The rollout of ADAS and autonomous driving features has created a whole new set of challenges that die casting is perfectly suited to solve. I work with Tier 1 suppliers who provide these systems to major OEMs, and their requirements are incredibly strict.

First, alignment is everything. The mounting brackets for a stereo camera or a LiDAR unit cannot flex or distort with temperature changes. A tiny misalignment can cause the system to misjudge distances, with obvious safety implications. Die casting produces parts with exceptional stiffness and dimensional stability11, ensuring the sensors stay pointed exactly where they need to be. Second, the electronics are sensitive. The housings we make for these modules must protect the components from electromagnetic interference (EMI) and dissipate the heat they generate. Aluminum is a great material for this. Finally, these parts need to integrate complex features for sealing and mounting in a very compact space. Once again, the ability of die casting to create complex net-shape parts makes it the ideal solution for this cutting-edge technology.

Conclusion

Die casting is a cornerstone of modern automotive manufacturing, producing everything from powertrain housings to critical EV battery trays. It enables the lightweight, strong, and complex parts that drive automotive innovation8 forward.

-

Explore this resource to understand the fundamentals of die casting and its significance in automotive parts production. ↩

-

This link will provide insights into the various automotive parts that benefit from die casting technology. ↩

-

Learn about the critical role of powertrain components in vehicle performance and how die casting enhances their design. ↩

-

This resource will explain the manufacturing process of battery trays and their role in EV performance. ↩

-

Find out how shock towers contribute to vehicle stability and how die casting optimizes their production. ↩ ↩

-

Explore the importance of electronic enclosures in vehicles and how die casting enhances their design. ↩

-

Discover the features and importance of ADAS systems in vehicles and how die casting supports their functionality. ↩

-

Explore how die casting is driving innovation in the automotive industry and shaping the future of vehicle design. ↩ ↩

-

Explore the importance of EMI shielding in automotive electronics and how die casting contributes to it. ↩

-

Understand the critical role of thermal management in EVs and how die casting aids in this process. ↩

-

Learn about the concept of dimensional stability and its significance in producing precise automotive parts. ↩