The lightweight of Aluminum Die-casting Battery Housing

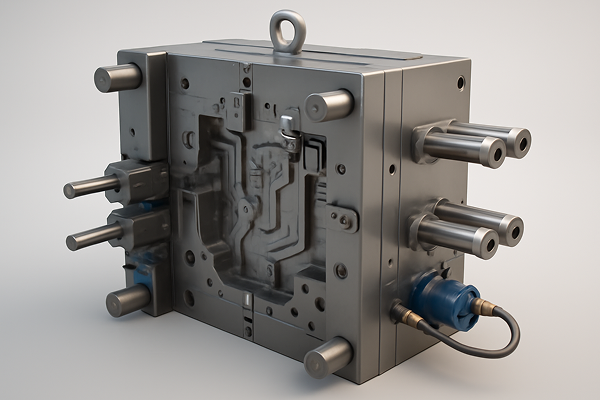

The lightweight of EV Battery Housing In addition to the lightweight of the body structure, the battery pack itself also needs to be lightweight. The lightweight of the battery housing is one of the directions of efforts. Especially for battery packs of pure electric vehicles, the pursuit of high mileage on the premise of the […]