A small surface flaw on a critical part can lead to an entire batch being rejected. This wastes time, increases costs, and can damage your reputation with the end customer.

The most common surface defects on aluminum die castings are porosity, cold shuts, flow marks, misruns, shrinkage defects, and blisters. These flaws are usually caused by problems with gas entrapment, molten metal temperature and flow, or inconsistent cooling during solidification.

In my 20+ years on the factory floor and working with clients, I’ve learned that a surface defect is never just a cosmetic issue. For the EV and automotive parts my team and I specialize in, a tiny flaw can compromise a seal, weaken a structural point, or create a spot for corrosion to start. Understanding what these defects look like and what causes them is the first and most important step. It’s the key to moving from firefighting quality problems to preventing them from ever happening in the first place. Let’s look at these common issues one by one.

What are the most common surface defects in aluminum die casting production?

You’ve received a batch of parts, but some just don’t look right. Without a clear way to identify and name the defects, you can’t have an effective conversation with your supplier about fixing them.

The most frequent defects are flow-related issues like cold shuts and misruns, gas-related problems like porosity, and solidification issues like shrinkage. Each has a distinct visual cue that points directly to a specific problem within the casting process.

During my early days on the line, my supervisor trained me to spot these issues with just my eyes and a good light. He would say, "The part is telling you a story about what happened inside that machine." He was right. A swirly pattern, a sharp line, a tiny pinhole—they are all clues. For a quality engineer or a purchasing director, knowing these clues is critical for evaluating a supplier’s capabilities. It’s not about memorizing a textbook; it’s about understanding the language of the casting process. When you can correctly identify a defect, you are in a much better position to ask your supplier targeted questions about their process control1, from their die temperature management to their vacuum system.

Common Defects at a Glance

| Defect Type | Visual Description | Primary Cause |

|---|---|---|

| Porosity | Small, round pinholes or voids on the surface. | Trapped gas or air. |

| Cold Shut | A fine line or crack where two metal fronts failed to fuse. | Low metal or die temperature. |

| Misrun | The part is incomplete because the cavity didn’t fill. | Insufficient shot speed or low temperature. |

| Shrinkage | A depression or sunken area on the surface. | Inadequate feeding of molten metal during cooling. |

| Blister | A raised bump or bubble on the surface. | Trapped gas below the surface expanding. |

You are dealing with parts that must be completely airtight, but they keep failing pressure tests. You suspect porosity2, but the defects are so small they are hard to see, making them difficult to diagnose and solve.

Gas porosity appears as small, typically spherical pinholes or voids on the surface or just below it. They are caused by air or hydrogen gas getting trapped in the molten aluminum during the injection and solidification phases of the casting cycle.

Porosity is one of the biggest enemies for parts like motor controller housings or battery enclosures, where sealing is non-negotiable. I once worked on a project where a customer’s parts were failing leak tests at a high rate. The surface looked clean to the naked eye. However, once we machined the surface for an O-ring groove, we exposed a layer of subsurface porosity. The root cause was twofold: turbulence during the injection phase was trapping air, and the raw material had a high level of dissolved hydrogen. We solved this by implementing a two-stage fix. First, we optimized the gating system and shot profile to ensure a smooth, laminar flow of metal into the die. Second, we installed a vacuum-assist system on the die to pull out air from the cavity just before the shot. This combination eliminated the porosity and brought the leak test failure rate to zero.

What causes cold shuts, flow marks, and misruns in die cast components?

The parts you received have visible lines, swirly patterns, or incomplete sections. These flow-related defects are unacceptable, causing an entire shipment to be put on hold and threatening your production timeline.

Cold shuts, flow marks, and misruns are all caused by the molten aluminum cooling down too quickly. This can be due to a low metal temperature, a die that is too cold, or an injection speed that is too slow to fill the cavity before solidification begins.

I think of these as "traffic jam" defects. The molten metal is trying to get to its destination, but something slows it down and causes problems. A cold shut is like two lanes of traffic meeting but not merging smoothly, leaving a line between them. Flow marks are like the turbulence left behind by a car moving too slowly. A misrun is the most extreme case—the traffic stops completely before it reaches the end of the road. I had a case with a large, thin-walled housing that consistently showed flow marks3. Our simulations showed that the die temperature was dropping in the area farthest from the gate. The metal was cooling just enough to get sluggish before it finished filling. The solution was to add a dedicated thermal control channel to that specific area of the die. By keeping the tool at a consistent, optimal temperature, we ensured the metal stayed fluid, and the flow marks vanished completely.

Why do shrinkage defects and blisters occur during aluminum die casting?

Parts look fine coming out of the die, but after machining or heat treatment, new defects appear. Depressions (shrinkage) or bubbles (blisters4) emerge, forcing you to scrap expensive, nearly finished components.

Shrinkage defects occur when sections of the casting solidify without enough molten metal to feed them, causing the surface to sink in. Blisters are caused by trapped gas under the skin of the part, which expands and creates a bubble when the part is heated.

These are some of the trickiest defects because they can be latent. Shrinkage is a natural phenomenon—metal shrinks as it cools. Our job is to manage it. On a part with a thick boss, if we don’t design proper overflows or use sufficient injection pressure, the thick section will pull material from the surface as it cools, causing a sink mark. Blisters are even more frustrating. I remember a client who called us because their parts were developing bubbles after being powder-coated and baked. The issue was traced back to excessive die lubricant. Tiny droplets were getting vaporized and trapped just under the surface during the shot. The parts looked perfect until the heat from the baking oven caused that trapped gas to expand. We had to fine-tune our die spray process, using an automated system to apply the absolute minimum amount of lubricant needed. It solved the problem and reinforced a key lesson: everything in the process matters.

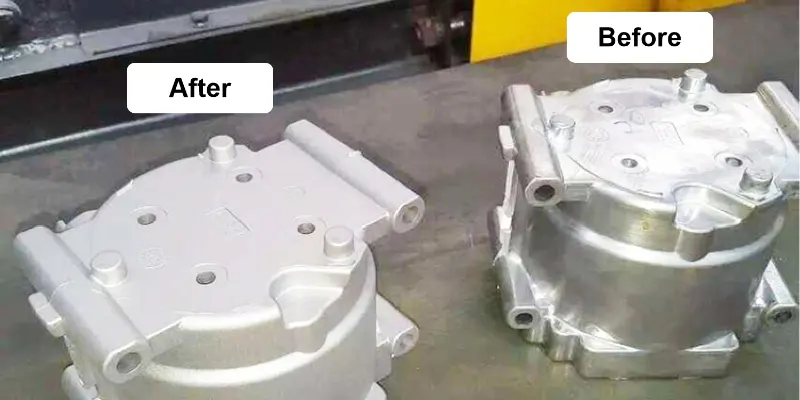

How can surface finishing techniques help reduce die casting surface defects?

You have a batch of parts with minor surface imperfections. Scrapping them is too costly, but you can’t ship them as-is. You need a reliable way to correct these minor flaws without compromising the part’s integrity.

Surface finishing techniques like shot blasting, vibratory deburring, and sanding can correct minor cosmetic flaws like flow marks or handling scratches. For porosity issues affecting sealing, impregnation can be used to fill the voids and make the part pressure-tight.

It’s important to be clear: surface finishing is a corrective action, not a substitute for a good casting process. However, for many applications, it’s a planned and necessary step. For example, most of our parts go through a controlled shot blasting5 process. This removes any parting line flash and creates a uniform, matte texture that is perfect for painting or powder coating. It can also hide minor flow marks. In cases of porosity in a hydraulic component, we have used vacuum impregnation6. This process pulls a vacuum on the parts and then floods them with a sealant resin, which is drawn deep into the pores. While effective, I always tell my customers that we should focus on eliminating the porosity in the first place. Relying on finishing to fix a fundamental process problem is never a good long-term strategy. The best approach is to make a great part from the start.

What new technologies are improving defect detection and prevention in die casting?

Your quality standards7 are getting stricter, and project timelines are getting shorter. Relying on manual inspection alone is slow and prone to error, and you need better tools to prevent defects before they happen.

Modern die casting relies on simulation software (like Moldflow) to predict and prevent defects in the design phase. During production, real-time process monitoring tracks every machine cycle, while automated AI-powered vision systems are now being used for faster, more reliable defect detection.

Technology has completely changed how we approach quality. Ten years ago, we relied heavily on trial and error. Today, before we even order the steel for a mold, my team runs extensive flow simulations. This software acts like a crystal ball, showing us exactly how the metal will fill the cavity and highlighting potential hotspots for porosity or cold shuts8. This allows us to perfect the gating and cooling systems digitally, saving months of physical trials. During production, every one of our machines is equipped with sensors that monitor dozens of parameters on every single shot—pressure, speed, temperature. This real-time data ensures process stability. The next step, which we are actively exploring, is AI vision systems. These cameras can inspect parts in seconds, identifying tiny defects a human might miss after hours of repetitive work. These tools help us move from detecting defects to actively preventing them.

Conclusion

Understanding surface defects9 is key to achieving high-quality aluminum die castings10. By identifying their root causes and using modern technology for prevention, we can produce reliable, high-performance parts that meet the strictest industry standards.

-

Learn about process control and its importance in maintaining quality in die casting. ↩

-

Discover the causes of porosity in aluminum die castings and how to prevent it. ↩

-

Understand the formation of flow marks and their impact on die casting quality. ↩

-

Discover the reasons behind blisters in aluminum die castings and how to address them. ↩

-

Learn how shot blasting can enhance the surface quality of die cast components. ↩

-

Find out how impregnation can help seal porosity issues in aluminum die castings. ↩

-

Understand the quality standards that aluminum die castings must meet in the industry. ↩

-

Find out what cold shuts are and how they affect the quality of die cast components. ↩

-

Explore this link to understand the various types of surface defects and their implications in die casting. ↩

-

Learn about aluminum die castings and the common defects that can occur during the process. ↩