Worried that microscopic contamination1 on your supplied parts could cause a major system failure? This risk leads to costly recalls and damages your brand’s reputation with every faulty component.

VDA 19.12 guarantees part cleanliness by providing a standardized process for inspecting technical cleanliness3. It defines how to extract, analyze, and report particulate contamination, ensuring that components meet the strict requirements needed for modern, high-performance automotive systems4.

As an engineer on the front lines, I have seen the damage that a single stray particle can do. For a Supplier Quality Engineer5 or a Purchasing Director, understanding this standard is no longer optional. VDA 19.1 isn’t just a document we keep on a shelf; it’s a critical part of our daily production and quality assurance process. Let’s break down what this standard means in practice and why it’s the gold standard for ensuring the reliability of your components.

What Makes the Latest VDA 19.1 Standard So Important?

Relying on outdated cleanliness standards for modern parts? This leaves you exposed to new types of contamination from EV components6, which can lead to failures the old specs never considered.

The latest VDA 19.1 standard (3rd Edition) is crucial because it is fully harmonized with ISO 16232. It provides updated, detailed guidance for the complex cleanliness requirements of electric vehicles and other advanced automotive systems.

The German Association of the Automotive Industry (VDA) created this standard to bring order to a complex problem. The key is that VDA 19.1 is now essentially identical to ISO 16232. This creates a single, global language for technical cleanliness3. For a global Purchasing Director, this means a cleanliness specification from a supplier in Germany means the exact same thing as one from our facility. The latest edition is a big step forward because it forces suppliers to think about the entire process chain. It’s not just about a final cleaning step. It’s about preventing contamination during casting, machining, handling, and even packaging. When we develop a new motor controller housing for an EV project, we use the standard to guide our process design from the very beginning. This proactive approach ensures we deliver parts that are ready for immediate integration into our customer’s assembly line, with no extra cleaning required.

How is a VDA 19.1 Cleanliness Test Actually Performed?

You just received a cleanliness report7 full of codes and numbers. But what does it mean? Not understanding the testing process makes it impossible to verify if the supplier is truly meeting your requirements.

A VDA 19.1 test extracts particles from a component using a specified method like rinsing. These particles are captured on a filter, which is then analyzed under a microscope to count, measure, and classify them.

At EMP Tech, we have our own dedicated cleanroom8 and laboratory to perform these tests. For an SQE, seeing this capability firsthand provides a lot of confidence. The process is meticulous and follows a clear, repeatable path to ensure accurate results. Here is a simplified breakdown of the steps involved:

| Step | Action | Purpose |

|---|---|---|

| 1. Extraction | The part is washed with a special, ultra-clean fluid inside a controlled environment. This can be done by rinsing, spraying, or using ultrasonic baths. | To carefully remove all loose particles from the component’s surfaces without damaging the part or adding new contamination. |

| 2. Filtration | The fluid from the extraction step is passed through a very fine filter membrane. | To capture all the extracted particles on a single surface for analysis. |

| 3. Analysis | The filter membrane is placed under a high-power automated microscope9. The system scans the filter and analyzes every particle. | To determine the quantity, size, and type (metallic, non-metallic, fiber) of the contaminants. |

| 4. Reporting | The data is compiled into a standardized report, often resulting in a Cleanliness Code (CCC)10. | To provide a simple, clear, and comparable result that shows if the part passed or failed the customer’s specification. |

This detailed process removes all guesswork. It gives us and our clients hard data, proving that our components meet the demanding cleanliness levels needed for today’s vehicles.

Why is This Level of Cleanliness Crucial for Automotive Components?

It can be tempting to see cleanliness specs as "over-engineering". But ignoring a single microscopic particle can jam a valve or short a circuit, causing a complete system failure down the road.

Extreme cleanliness is crucial because sensitive systems like EV electronics, high-pressure fuel injectors, and ABS brake modules can be completely disabled by tiny particles. This directly impacts vehicle safety, reliability, and warranty costs.

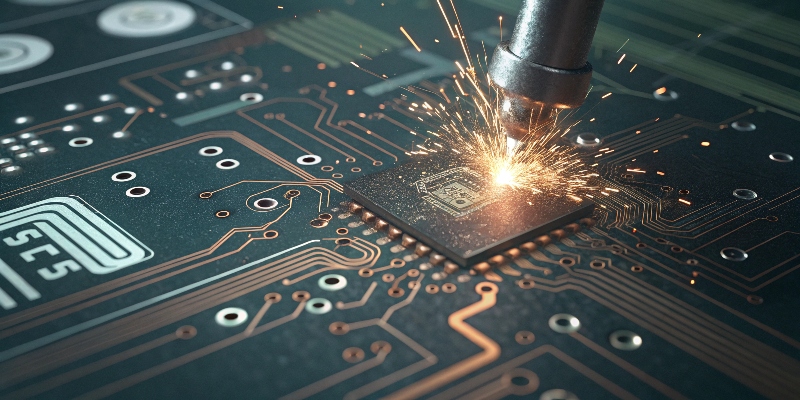

In the past, cleanliness was mostly a concern for hydraulic and fuel systems. Today, with the complexity of electric vehicles and driver-assistance systems, it is critical for almost every major component we produce. A single conductive metallic fiber, almost invisible to the naked eye, can cause a catastrophic failure if it lands in the wrong place. We’ve worked on projects for German Tier 1s where the cleanliness requirements for an inverter housing were as strict as those for a fuel injector. That is because a particle could cause a short circuit on the power electronics board, disabling the vehicle.

Here’s where contamination can cause major problems:

| Vehicle System | Component | Potential Failure from Contamination |

|---|---|---|

| EV Powertrain | Inverter / Controller Housing | Metallic particles cause short circuits on the PCB. |

| Braking System | ABS / ESC Valve Block | Particles cause valves to stick, disabling safety features. |

| Engine System | High-Pressure Fuel Injector | Debris clogs the nozzle, leading to poor performance and emissions. |

| Steering System | Electric Power Steering Unit | Abrasive particles cause premature wear on gears and bearings. |

That is why we guarantee that our components are compliant with VDA 19.1 and ISO 16232. Our parts are delivered clean enough to go straight to our customer’s final assembly line. This saves our clients time and money, and completely removes the risk of re-contamination from a secondary cleaning process.

Conclusion

VDA 19.1 is more than a standard; it is your insurance policy for vehicle reliability. Partnering with a supplier who has mastered this process is essential to reducing risk in today’s automotive industry.

-

Understand the serious implications of contamination in automotive components and how to mitigate risks. ↩

-

Explore this link to understand how VDA 19.1 ensures part cleanliness and reliability in automotive systems. ↩

-

Learn about technical cleanliness and its critical role in preventing system failures in vehicles. ↩ ↩

-

Find out the latest cleanliness requirements for automotive systems to ensure safety and reliability. ↩

-

Learn about the critical role Supplier Quality Engineers play in maintaining part cleanliness. ↩

-

Understand the unique cleanliness challenges posed by EV components in the automotive industry. ↩

-

Get insights into what a cleanliness report entails and how it impacts supplier evaluations. ↩

-

Explore the significance of cleanrooms in testing and ensuring the cleanliness of automotive parts. ↩

-

Explore how automated microscopes enhance the accuracy of cleanliness testing in automotive parts. ↩

-

Discover the meaning of Cleanliness Code (CCC) and its importance in evaluating part cleanliness. ↩