Traditional finishing methods for die-cast parts are slow and inconsistent. They struggle to meet the precision demands of modern vehicles, leading to scrap, delays, and potential quality failures.

Laser technologies are revolutionizing aluminum die casting by providing ultra-precise, non-contact solutions for cutting, welding, and cleaning. This improves part quality, enables complex designs for lightweighting, and ensures the hermetic sealing required for critical electric vehicle components.

In my 20 years in die casting, I have seen many technologies come and go. But lasers are different. They are not just an improvement; they are a complete game-changer. What used to require multiple, messy, mechanical steps can now be done in seconds with a beam of light. For my team and our Tier 1 customers, this has opened the door to designs and quality levels that were once unimaginable. Let’s explore how these different laser applications work.

How Does Laser Cutting Handle Complex Aluminum Components?

Trimming and deburring intricate die-cast parts with mechanical presses or manual tools is difficult. It’s slow, wears out tools, and can easily damage the delicate, thin-walled designs used in modern cars.

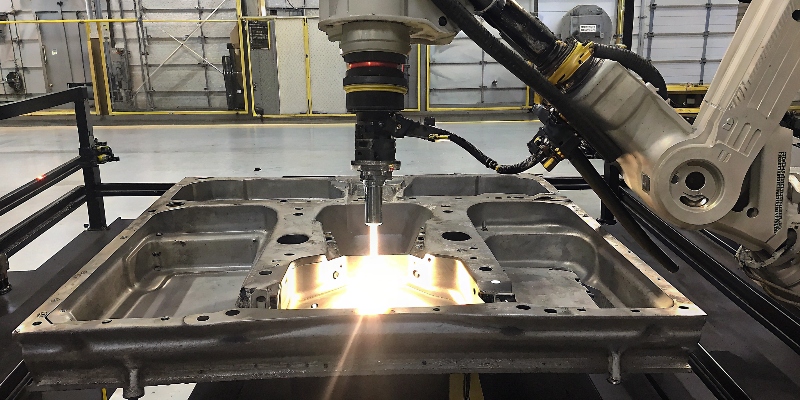

Laser cutting uses a highly focused beam of light to vaporize metal along a precise path. This non-contact process allows for the clean and rapid trimming of complex shapes, holes, and features without putting any mechanical stress on the part, ensuring perfect results every time.

Think of laser cutting1 as a scalpel made of light. It is incredibly precise and creates a very clean edge. In die casting, we often produce parts with excess material called "flash" or runners that need to be removed. Traditionally, this was done with a large, heavy trim press. But for parts with complex geometries, a trim die is expensive and can cause micro-cracks or distort the part. I remember a project with a complex heat sink where the trim die kept breaking because of the fine fin design. We switched to a 5-axis laser cutting cell. This not only solved the breakage issue but also gave us a much cleaner edge and a faster cycle time. The laser can follow any path we program, no matter how complex.

Comparing Cutting Methods

The difference between laser cutting and traditional methods is stark, especially when precision is critical.

| Feature | Laser Cutting | Trim Press / CNC Machining |

|---|---|---|

| Precision | Very High (±0.1mm) | Moderate to High |

| Mechanical Stress | None | High (trim press) or Low (CNC) |

| Tool Wear | None | High (dies wear out) |

| Shape Complexity | Virtually unlimited | Limited by die/tool geometry |

| Heat Affected Zone | Very small | None (mechanical) |

How Can Laser Welding Improve a Part’s Integrity and Sealing?

Joining aluminum castings or sealing them with traditional welding is a huge challenge. The high heat input from TIG or MIG welding often warps the part, creating leaks in components that must be perfectly sealed.

Laser welding delivers a concentrated burst of energy that creates a deep, narrow, and strong weld with a very small heat-affected zone. This minimizes distortion, making it the perfect method for creating the hermetic seals required for EV battery enclosures and electronics housings.

For many EV components, like motor controllers or on-board chargers (OBCs), the housing must be completely sealed from moisture and dust. This is an IP67 or IP6K9K requirement. In the past, this was often done with gaskets and dozens of screws. This adds weight, cost, and many potential points of failure. Laser welding allows us to create a continuous, metallurgically bonded seal. I worked closely with a German Tier 1 supplier on an inverter housing that had to be helium leak-tight. Our initial attempts with TIG welding caused the thin housing walls to warp, making a consistent seal impossible. We developed a process using a fiber laser to weld the lid on. The weld was so fast and the heat input so low that there was zero measurable distortion. The parts passed every single leak test.

Why Laser Welding is Superior for Sealing

The process creates a much more reliable seal compared to other methods, especially for the high demands of the automotive industry.

| Method | Heat Input / Distortion | Sealing Performance | Speed |

|---|---|---|---|

| Laser Welding | Very Low / Minimal | Excellent (Hermetic) | Very Fast |

| TIG/MIG Welding | High / Significant | Good, but risks porosity/cracks | Slow |

| Gasket and Fasteners | None / None | Good, but can degrade over time | Moderate |

Why Is Laser Cleaning Used for Surface Preparation?

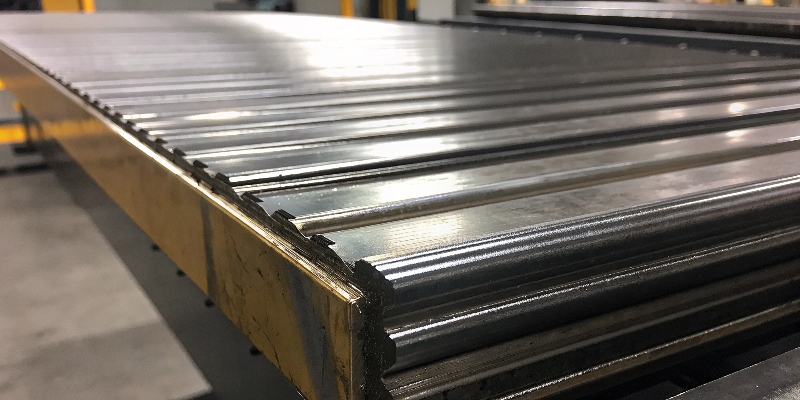

Preparing an aluminum surface for welding or adhesive bonding is critical. Traditional methods like chemical washing, grinding, or sandblasting are messy, hard to control, and bad for the environment.

Laser cleaning, or ablation, uses short, powerful pulses of light to instantly vaporize oxides, grease, and other contaminants from a surface without touching the aluminum underneath. This creates a perfectly clean, dry, and consistently textured surface ideal for bonding or welding.

The strength of a weld or an adhesive bond is only as good as the surface preparation. For years, my teams struggled with the inconsistencies of chemical baths and manual grinding. One day the bond would be perfect; the next, we would see failures. Laser cleaning solved this. The process is incredibly intelligent. We can tune the laser’s energy so it is absorbed by the dark oxide layer and contaminants but reflected by the shiny, clean aluminum base metal. This means the process automatically stops as soon as the surface is clean. It’s a purely digital and repeatable process. We recently integrated a laser cleaning2 station right before an adhesive bonding application on a structural component. It completely eliminated the inconsistent results we saw with our old chemical process. Our bond strength became reliable and predictable.

How Do Lasers Support Automotive Lightweighting and EV Goals?

Lightweight designs and EV systems require parts that are complex, thin-walled, and perfectly sealed. Traditional manufacturing methods often fall short, limiting what engineers can design.

Lasers are a key enabler for lightweighting and EV technology. They allow for the precise manufacturing of intricate, weight-optimized parts, provide the mission-critical hermetic seals for batteries and electronics, and ensure clean surfaces for reliable electrical and thermal connections.

Lasers are not just improving old processes; they are enabling entirely new design philosophies. As we push for lighter cars and more efficient EVs, we need every component to be optimized. Lasers give us the tools to do that. For example, an engineer can design a complex, single-piece structural part that consolidates what used to be five separate stamped and welded pieces. A traditional trim press3 could never finish this part, but a 5-axis laser can cut it perfectly. An EV battery enclosure needs to be both lightweight and absolutely leak-proof to protect the cells. Laser welding is the only technology that can reliably deliver that combination of strength and sealing at high volume. The synergy between die casting and laser technology is pushing the boundaries of what is possible in automotive engineering.

| Laser Technology | Contribution to Lightweighting & EVs |

|---|---|

| Laser Cutting | Enables intricate, weight-optimized designs; trims thin walls without damage. |

| Laser Welding | Creates strong, lightweight, hermetic seals for batteries and power electronics. |

| Laser Cleaning | Ensures clean, reliable surfaces for electrical busbar connections and bonding. |

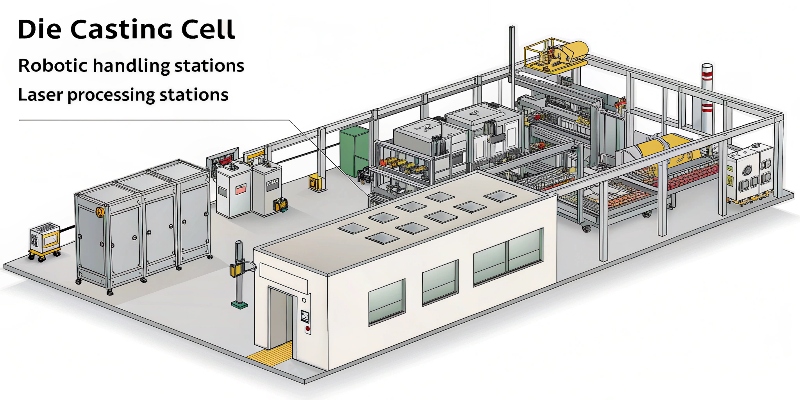

How Can Laser Processes Be Integrated into High-Volume Production?

Introducing a new technology like lasers to a fast-paced production line can seem intimidating. You might worry about the complexity, the cost, and whether it can keep up with your cycle times.

Modern laser systems are designed for automation and are easily integrated into high-volume production cells. Robots seamlessly move parts from the die casting machine to laser stations for cutting, welding, or cleaning, all within the required manufacturing cycle time.

The key to using lasers in high-volume production is automation. It is not practical to have an operator manually loading parts into a laser machine every 60 seconds. Instead, we design fully integrated manufacturing cells4. I have led the development of several of these cells for our customers. A typical layout looks like this: a robot extracts the hot casting from the die cast machine, places it in a cooling station, and then moves it into an enclosed laser cell. Inside the cell, the laser performs its task—for example, trimming the flash and deburring critical holes. The whole process takes seconds and is completed while the next part is being cast. While the initial investment is higher than a simple trim press, the return is significant. You eliminate tool wear, reduce manual labor, dramatically improve quality, and gain the flexibility to run different parts on the same line with a simple software change.

Conclusion

Laser technology is no longer a niche specialty; it is a core manufacturing process. It provides the precision, quality, and flexibility needed to produce the advanced aluminum die castings that power modern mobility.

-

Discover the precision and efficiency benefits of laser cutting compared to traditional methods. ↩

-

Discover the innovative process of laser cleaning and its benefits for surface preparation. ↩

-

Learn about the drawbacks of trim presses and how they affect production efficiency. ↩

-

Understand the concept of manufacturing cells and their impact on production efficiency. ↩