Porosity1 in your die castings causes leaks and structural failures. These hidden voids force you to scrap expensive parts, threatening your entire project timeline and creating massive production headaches.

Solving porosity requires a combination of strategies: optimizing mold venting2 and a vacuum system3, tightly controlling injection parameters4 and metal temperature5, using high-quality degassed aluminum6, and maintaining a clean, well-designed mold. This holistic approach minimizes both gas and shrinkage porosity7.

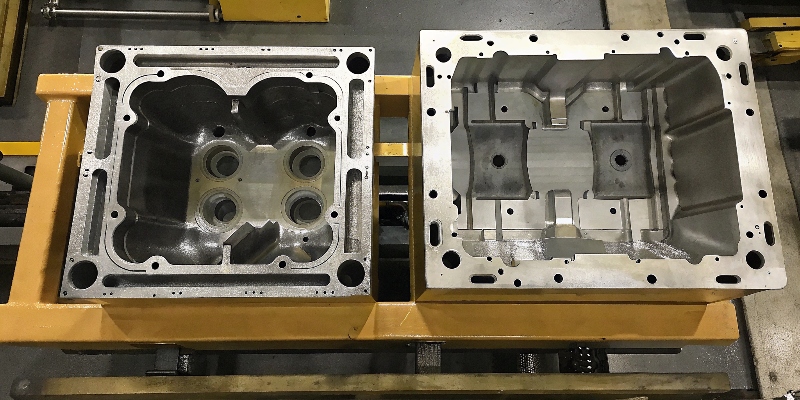

Porosity is the die caster’s oldest enemy. For a Supplier Quality Engineer, it’s the root cause of many field failures. For a Purchasing Director like Simon, it represents a huge risk in supplier reliability. In my work with complex new energy vehicle housings, which must be 100% leak-proof, we don’t just inspect for porosity—we systematically eliminate the conditions that create it. This requires a deep dive into every stage of the process, from mold design8 to melt treatment.

How Can Optimizing Mold Venting and a Vacuum System Reduce Porosity?

Trapped air causes gas porosity in your castings. These hidden bubbles become leak paths and weak spots that lead to field failures. Effective venting and vacuum systems are the solution.

Vents act as escape channels, allowing air to exit the cavity as metal rushes in. A vacuum system actively pulls the air out before injection. Both methods prevent gas from being trapped and compressed, ensuring a dense, sound casting free from gas porosity.

For years, we relied solely on conventional vents. These are tiny, precisely machined channels, often just 0.1-0.2 mm deep, that let air out but stop the thicker molten aluminum. However, for the complex EV controller housings we make today, with their thin fins and deep pockets, vents alone are often not enough. Air gets trapped in isolated corners. This is where vacuum-assisted die casting becomes a game-changer. By pulling a near-perfect vacuum in the mold cavity before the shot, we remove the air entirely. This not only prevents gas porosity but also allows the metal to fill intricate sections more easily. It’s an investment, but for parts requiring high integrity and zero leaks, it’s the gold standard.

| Technique | How It Works | Best For |

|---|---|---|

| Conventional Vents | Passive channels that let air escape under pressure. | Standard parts with simple geometries. |

| Chill Vents | Vents placed in cooled sections to freeze metal quickly, trapping air/oxides. | Capturing the ‘first wave’ of contaminated metal. |

| Vacuum Assistance | Actively removes >90% of air from the cavity before injection. | Complex, thin-walled, or high-integrity parts (e.g., EV housings). |

How Do Metal Temperature and Injection Speed Control Porosity?

Uncontrolled temperatures and injection speeds create porosity. This process instability causes turbulence and premature solidification, leading to scrapped parts. The solution is precise, real-time process control for every shot.

Low metal temperature or a cold mold causes premature solidification, leading to shrinkage porosity. High injection speed creates turbulence, trapping air and causing gas porosity. The key is finding the perfect balance to ensure smooth, progressive filling of the mold before the metal solidifies.

This is a delicate dance between physics and practice. You want the metal to flow quickly enough to fill the entire cavity before it starts to freeze, but not so fast that it becomes turbulent and atomizes, trapping gas like a shaken soda can. We don’t just set a single ‘speed’; we design a multi-stage injection profile.

- Slow Shot Phase: The initial movement of the plunger is slow and gentle. This pushes the air out of the runner system and towards the vents without turbulence.

- Fast Shot Phase: Once the runners are full, the speed ramps up dramatically to fill the part cavity in milliseconds. This speed must be high enough to avoid cold shuts but low enough to prevent spraying.

I remember a project where shrinkage porosity kept appearing near a thick boss. Our solution was counterintuitive: we slightly increased the local mold temperature in that area while slightly decreasing the final injection pressure. This allowed the thick section to be fed with liquid metal for longer, curing the shrinkage. It’s this level of fine-tuning that makes the difference.

Why Does Improving Die Design for Uniform Wall Thickness Reduce Porosity?

Uneven wall thickness causes shrinkage porosity. Thick sections cool slowly and starve for metal, creating hidden voids. Good DFM involves designing uniform walls to prevent this from happening.

Uniform wall thickness promotes even cooling and solidification across the entire part. This prevents hot spots where thick sections pull metal away from solidifying thin sections, which is the primary cause of shrinkage porosity. A uniform design ensures the part solidifies progressively towards the gate.

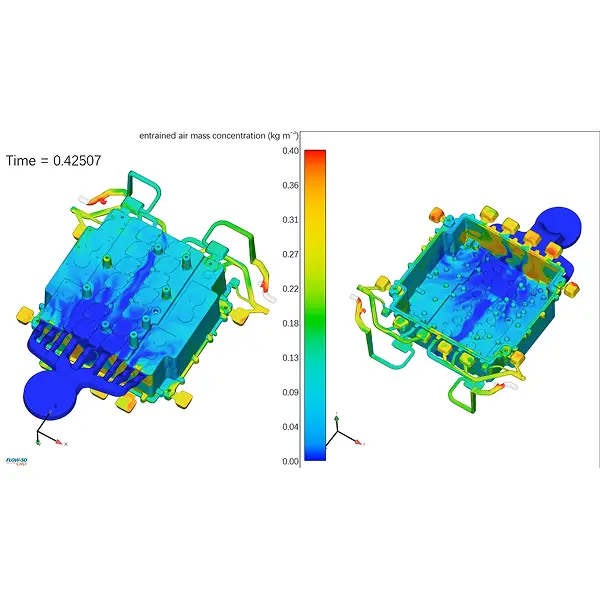

The first conversation I have with any customer’s design engineers is about DFM. We can’t always achieve perfectly uniform walls, but we can manage the transitions. The goal is to design the part so it solidifies like a wave, starting from the point furthest from the gate and moving progressively back towards it. This ensures the gate, the last part to freeze, can continuously feed molten metal to compensate for shrinkage. When a design has an isolated thick section, it becomes a ‘hot spot.’ It stays molten after the surrounding thin walls have solidified, but its connection to the gate is already frozen. As it cools and shrinks, it has nowhere to draw metal from, and a void forms. We use mold flow simulation9 to identify these potential hot spots early. Often, a simple design change, like adding a blended radius instead of a sharp corner or coring out a thick boss, can completely solve the problem before we ever cut steel for the mold.

How Do Degassing and Filtration Techniques Prevent Porosity?

Contaminated aluminum melt is full of dissolved gas and solid impurities. This contamination causes widespread porosity and inclusions, making a strong, leak-proof part impossible. Clean metal is the only answer.

Degassing removes dissolved hydrogen gas from the molten aluminum, preventing it from forming gas pores as the metal cools. Filtration uses ceramic foam filters to trap solid oxides and other non-metallic inclusions, ensuring only pure metal enters the mold. Both are critical for high-quality castings.

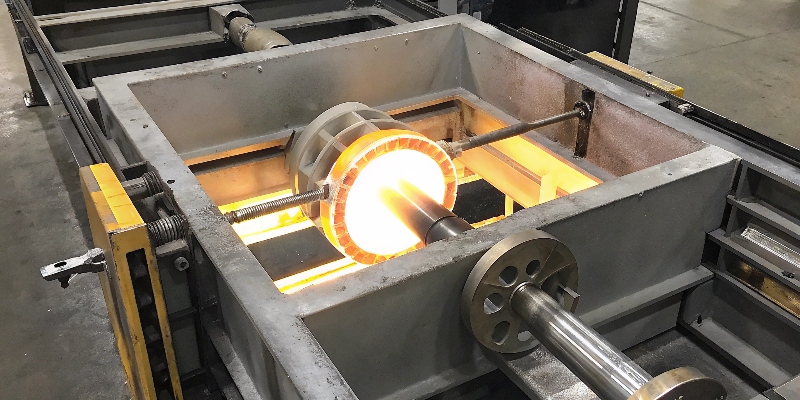

Molten aluminum acts like a sponge for hydrogen gas, absorbing it from the moisture in the air. When the aluminum solidifies, its ability to hold this gas drops dramatically, and the hydrogen comes out of solution, forming tiny, round gas pores throughout the casting. To combat this, we use a rotary degassing unit. It has a spinning graphite lance that pumps an inert gas, like argon or nitrogen, through the melt. This creates fine bubbles that collect the hydrogen and carry it safely to the surface. In addition to gas, the melt also contains solid oxides (dross). To remove these, we place a ceramic foam filter (CFF) in the runner system. It acts like a coffee filter, trapping these hard, brittle inclusions before they can enter the part cavity. For the high-integrity automotive parts10 we produce, degassing and filtration are not optional; they are standard procedure for every batch of metal we prepare.

How Can Real-Time Process Monitoring Help Adjust for Porosity?

The die-casting process can drift over a production run. A stable process can slowly change, suddenly producing parts with porosity. Real-time monitoring allows you to see and correct this instantly.

Real-time monitoring systems track key parameters like injection speed, pressures, and mold temperatures for every single shot. By comparing this data to a ‘golden’ reference shot, the system can instantly flag any deviation that could lead to porosity, allowing for immediate correction or part quarantine.

Modern die-casting is a science of milliseconds. We can’t see what’s happening inside the mold, but we can measure it with extreme precision. We capture the ‘shot curve’ for every part—a graph of the injection plunger’s velocity and the metal’s pressure over time. We save the curve from a known-good, X-ray-verified part as our ‘master’ or ‘golden’ curve. The monitoring system then overlays the curve of every subsequent shot on top of this master. If a variable changes—for example, if a vent starts to clog, causing back-pressure to rise slightly—the shot curve will deviate from the master. The system will immediately alert the operator. This is invaluable for a Quality Engineer, because it provides 100% traceability and data-driven proof of process stability. It moves quality control from reactive (finding bad parts later) to proactive (preventing bad parts from ever being made).

Why Is Proper Mold Maintenance and Cleaning Crucial to Prevent Porosity?

A dirty or worn-out mold creates defects. Clogged vents and old release agent residue cause porosity, ruining parts. A strict, preventative maintenance schedule is the only way to ensure consistency.

Regular cleaning prevents mold release agent and aluminum residue from building up and clogging vents, which causes gas porosity. Preventative maintenance ensures that seals are tight and components like ejector pins are not creating unintended leak paths for air to get sucked into the cavity.

A die-casting mold is a high-precision piece of equipment that endures incredible thermal and physical stress. It is not a ‘set it and forget it’ tool. At EMP Tech, every mold has a detailed preventative maintenance (PM) plan, just like a car. This isn’t something we do only when there’s a problem; it’s scheduled based on the number of shots produced. It’s this discipline that prevents problems like porosity from ever starting. A dirty mold is an unreliable mold. For a Purchasing Director like Simon, our strict PM program is a guarantee of consistent quality and on-time delivery, because it minimizes unexpected downtime and quality rejects.

| Maintenance Task | Frequency | Impact on Porosity |

|---|---|---|

| Vent & Parting Line Cleaning | Every 8-10 hours | Prevents clogged vents, which trap gas. |

| Cooling Channel Flush | Weekly | Ensures uniform mold temperature, preventing shrinkage. |

| Ejector Pin Inspection | Weekly | Prevents air from being drawn into the mold around worn pins. |

| Full Mold Teardown | Per shot count (~50k) | Complete inspection and refurbishment of all components. |

Conclusion

Solving porosity isn’t about one magic fix. It requires a systematic approach that combines smart design, precise process control, clean material, and disciplined maintenance to guarantee sound, reliable castings.

-

Understanding porosity is crucial for improving casting quality and preventing defects. ↩

-

Learn how effective mold venting can significantly reduce gas porosity in castings. ↩

-

Discover the benefits of vacuum systems in achieving high-quality, leak-proof castings. ↩

-

Understanding injection parameters is key to controlling porosity and ensuring quality. ↩

-

Explore the impact of metal temperature on casting quality and porosity. ↩

-

Learn why using degassed aluminum is essential for preventing porosity in castings. ↩

-

Understanding shrinkage porosity helps in designing better casting processes. ↩

-

Understanding mold design is crucial for minimizing defects like porosity. ↩

-

Explore how mold flow simulation can help identify potential issues before production. ↩

-

Discover the significance of die casting in producing high-integrity automotive components. ↩