Struggling with leaky EV die-cast housings? These failures create costly delays and damage your reputation. A structured approach from design to production is the key to achieving perfect airtightness.

Achieving airtightness in EV die-cast housings requires a multi-stage approach. It starts with Design for Manufacturability (DFM)1 to eliminate risks, followed by strict die-casting process control2 to prevent porosity3, and finally, validated leak testing methods4 to confirm every part meets specifications.

Getting this right isn’t about a single magic fix. It’s about making smart decisions at every step of the manufacturing journey. I’ve seen many projects succeed or fail based on these choices. For Purchasing Directors, it means finding a partner who controls the entire process to ensure reliability. For Supplier Quality Engineers, it’s about having confidence in the data and methods behind each part. Let’s break down exactly what you need to focus on, starting from the very beginning: the design phase.

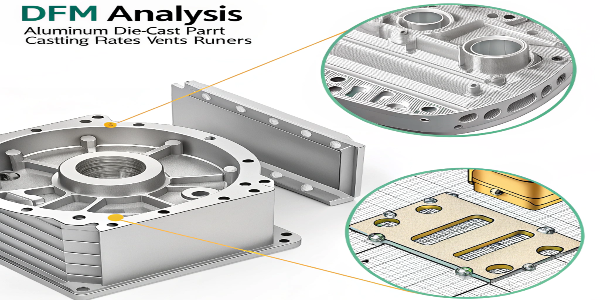

How Does Early DFM Prevent Leaks in Die-Cast Parts?

Do you find design flaws only after casting? This late discovery leads to expensive mold modifications and project delays. Proactive Design for Manufacturability (DFM) analysis is your best defense.

DFM analysis prevents leaks by optimizing part geometry for die casting. Experts review wall thickness5, fillet radii6, and draft angles7 to ensure smooth molten metal flow, which minimizes turbulence and trapped gas—the primary causes of porosity and future leak paths.

From my experience, over 50% of leak issues can be traced back to the initial part design. A design might look great on paper but be impossible to cast without defects. This is where early collaboration is so important. I remember a project with an OBC housing where the initial design had several thick sections right next to very thin walls. The mold flow simulation8 my team ran predicted severe shrinkage porosity exactly where the sealing gasket would sit. By working with the customer’s engineers, we adjusted the wall transitions and added material to create a more uniform thickness. This small change, made before any steel was cut for the mold, saved them from months of production headaches and potential field failures. A good DFM process isn’t just about finding problems; it’s about providing solutions.

Key DFM Considerations for Airtightness

| Design Feature | Good Practice (Prevents Leaks) | Bad Practice (Causes Leaks) |

|---|---|---|

| Wall Thickness | Uniform thickness (e.g., 3-4 mm) | Abrupt changes from thick to thin |

| Fillet Radii | Generous radii at intersections | Sharp internal corners |

| Draft Angles | Adequate angles (1-2 degrees) | Insufficient or zero draft |

| [Ribs & Bosses]9 | Well-blended into main walls | Placed in isolated, hard-to-fill areas |

A proper DFM review provides a clear roadmap for a successful casting, making life easier for both the procurement team trying to stay on schedule and the quality team responsible for the final part.

What Casting Process Controls Are Critical for Airtightness?

Your part design is perfect, but you still face inconsistent quality and leaks. This means your casting process is unstable, creating hidden porosity defects. Strict, real-time process control is essential.

Critical process controls include managing melt and mold temperature10s, optimizing injection speeds and pressures11, and using a high-vacuum system12. These parameters directly influence metal flow, solidification, and gas evacuation, which are all essential for producing a dense, non-porous casting.

A great design and a perfect mold are only half the battle. Without a stable and repeatable casting process, you are just producing scrap. On a motor controller project for a German client, they demanded extremely high airtightness. We knew that even micro-porosity would cause a failure. My team focused on establishing a very precise process window. We used thermal imaging13 to monitor the mold temperature10 in real time, making sure it never varied by more than a few degrees. We also implemented a multi-stage injection profile, with a slow initial phase to let air escape before filling the cavity at high speed. The most important factor was our high-vacuum system12, which pulled nearly all the air out of the mold cavity before injection. This combination of controls allowed us to consistently produce parts that were not just visually clean, but structurally sound and free of the gas porosity that often causes leaks.

Critical Process Parameters for Airtight Parts

| Parameter | Importance for Airtightness | Risk of Poor Control |

|---|---|---|

| Melt Temperature | Affects fluidity and solidification time. | Too hot: gas absorption. Too cold: premature solidification. |

| Mold Temperature | Ensures proper metal flow and reduces thermal shock. | Inconsistent temps cause flow marks and shrinkage porosity. |

| Injection Profile | Controls how metal enters and fills the cavity. | High speed too early traps air; too slow causes cold shuts. |

| Vacuum Level | Removes air and gas from the cavity before injection. | Insufficient vacuum leads to gas porosity. |

For an SQE, seeing a supplier with this level of process monitoring provides huge confidence that quality is built-in, not just inspected-in.

What Are the Best Methods for Leak Testing Die-Cast Parts?

How can you be sure a part is truly airtight before shipment? A part passing a basic test can still fail in the field. Choosing the right testing method is critical.

For EV housings, the two primary methods are pressure decay testing14 for mass production and helium mass spectrometry15 for high-sensitivity needs. Pressure decay is fast and cost-effective, while helium testing can detect extremely small micro-leaks required for the most critical applications.

The test method must match the part’s function. The classic "dunk test" where you submerge a pressurized part in water is simply not reliable enough for modern EV components. Recently, we worked on an inverter housing that contained sensitive electronics cooled by a liquid loop. Any leak would be catastrophic. The customer’s SQE, much like Jure, specified a very strict leak rate that was impossible to verify with a simple pressure decay test. We had to invest in a helium mass spectrometer. This machine floods the part with helium, the smallest stable gas molecule, and then uses a detector to "sniff" for any atoms escaping. It can detect leaks thousands of times smaller than what a pressure test can find. We established a 100% inspection protocol using this method. While it’s a slower and more expensive process, it gave the customer absolute assurance that every single part we shipped would perform flawlessly.

Comparing Leak Testing Methods

| Feature | Pressure Decay Testing | Helium Mass Spectrometry |

|---|---|---|

| Sensitivity | Good for moderate leaks | Excellent for micro-leaks |

| Speed | Fast (seconds per part) | Slower (minutes per part) |

| Cost | Low initial and operational cost | High initial and operational cost |

| Best For | 100% production line testing for standard requirements. | High-value parts, safety-critical components16, R&D. |

For a purchasing director, understanding these options is key to balancing cost and risk. For some parts, pressure decay is sufficient. For others, the added cost of helium testing is a necessary insurance policy against field failures.

Conclusion

Guaranteeing airtightness is not luck. It comes from rigorous DFM, controlled casting processes, and validated testing. This holistic approach ensures reliable, high-performance parts for any EV project.

-

Understanding DFM can help you optimize designs to prevent leaks and improve production efficiency. ↩

-

Learn how effective process control can enhance the quality and reliability of die-cast products. ↩

-

Discover the causes of porosity and effective strategies to eliminate it in your manufacturing process. ↩

-

Explore the most reliable testing methods to ensure your die-cast parts are airtight and meet specifications. ↩

-

Understanding the importance of wall thickness can help you design parts that are both strong and leak-free. ↩

-

Explore how proper fillet radii can prevent stress concentrations and improve the durability of die-cast components. ↩

-

Learn about the significance of draft angles in ensuring smooth ejection and reducing defects in die-cast parts. ↩

-

Mold flow simulation can predict issues in design, helping to avoid costly mistakes in production. ↩

-

Discover best practices for designing ribs and bosses to enhance structural integrity and manufacturability. ↩

-

Understanding the impact of mold temperature can help you achieve better flow and reduce defects in your castings. ↩ ↩

-

Learn how optimizing injection parameters can significantly impact the quality of die-cast parts. ↩

-

Discover how a high-vacuum system can enhance the quality of your die-cast products by reducing air entrapment. ↩ ↩

-

Learn how thermal imaging can improve process control and ensure consistent quality in die casting. ↩

-

Understand how pressure decay testing works and its effectiveness in identifying leaks in die-cast parts. ↩

-

Explore how helium mass spectrometry can detect micro-leaks, ensuring the integrity of critical components. ↩

-

Learn about the importance of ensuring airtightness in safety-critical components to prevent catastrophic failures. ↩