Sourcing complex, lightweight parts for modern cars is a huge challenge. The wrong manufacturing process leads to heavy parts, high costs, and quality failures, putting your entire project timeline at risk.

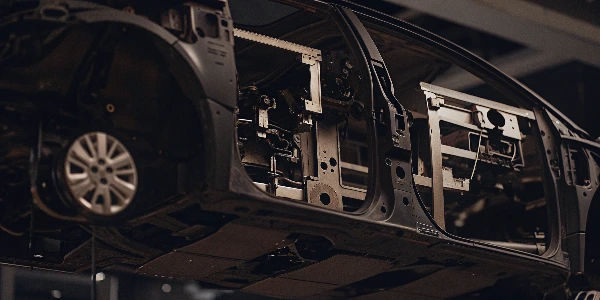

High-pressure die casting1 is essential for producing many critical automotive parts2. These include traditional components like transmission cases3 and engine blocks4, and is especially vital for electric vehicle parts5 like battery enclosures6, motor housings7, and power electronics8.

As a technical engineer who’s spent over 20 years in the die casting industry, I’ve seen this technology become the backbone of automotive manufacturing. For quality engineers and purchasing directors, understanding where and why die casting is used is key to making smart sourcing decisions. Let’s look at the specific applications and the process itself, especially as the industry shifts rapidly toward electric vehicles.

What Exactly is Die Casting in an Automotive Context?

You hear the term "die casting," but you may not be sure how it works. This can make it hard to discuss design requirements and potential issues with your suppliers.

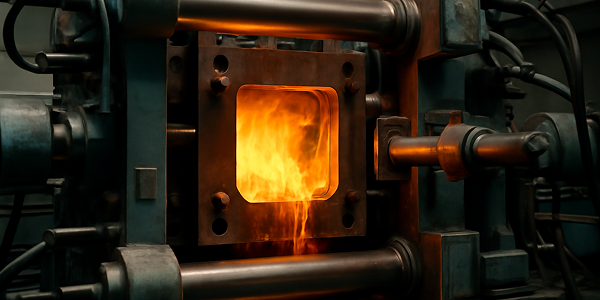

In the automotive industry, die casting is a process where molten aluminum is injected at high speed and pressure into a steel mold, called a die. It produces strong, precise, and complex metal parts very quickly.

The specific method we use is High-Pressure Die Casting, or HPDC. It’s the go-to process for automotive parts because of its precision and speed. On the shop floor, the difference is noticeable. We can produce a complex part, like a housing for a motor controller, in less than two minutes from one machine. The process involves three main steps:

- Injection: We inject a precise amount of molten aluminum alloy into the locked steel mold under extreme pressure. This pressure packs the metal into every tiny detail of the mold cavity.

- Cooling: The mold has internal cooling lines. These lines rapidly cool the molten metal, causing it to solidify into the final part shape. This speed is what gives die casting a major advantage.

- Ejection: Once the part is solid, the mold opens, and ejector pins push the finished casting out. Then the cycle immediately starts over again.

This high-speed, repeatable process allows us to create millions of identical parts that meet the strict tolerances required by the automotive industry.

Which Key Automobile Parts are Made Using Die Casting?

You need to source a wide range of automotive components. It can be difficult to know which manufacturing process is the best fit for each specific part you are responsible for.

Die casting is used for many parts, from traditional powertrain components like transmission cases3 and oil pans to critical electric vehicle parts5 like motor housings7, battery pack enclosures, and inverter covers.

The list of parts we manufacture with die casting is long and growing, especially with the rise of e-mobility9. The process is chosen for its ability to create parts that are both lightweight and strong, often combining many functions into a single, complex casting. I have worked on everything from simple brackets to massive structural components. Here’s a breakdown of some of the most common an an explanation of why die casting is the best choice for them.

| Component Category | Specific Die-Cast Parts | Why Die Casting is Chosen |

|---|---|---|

| ICE Powertrain | Transmission housings, engine blocks4, oil pans | Complex shapes, pressure tightness, high production volume. |

| EV Powertrain | Motor housings, battery enclosures6, inverter housings | Lightweighting, heat dissipation, EMI shielding. |

| Structural & Chassis | Shock towers, cross-car beams, subframes | High strength-to-weight ratio, part consolidation. |

I remember working on one of the first major EV motor controller housings for a German Tier 1 supplier. The main challenge was to combine high heat dissipation requirements with very strict airtightness specifications. Aluminum die casting was truly the only process that could achieve both of these goals at the production speed and cost required for the project.

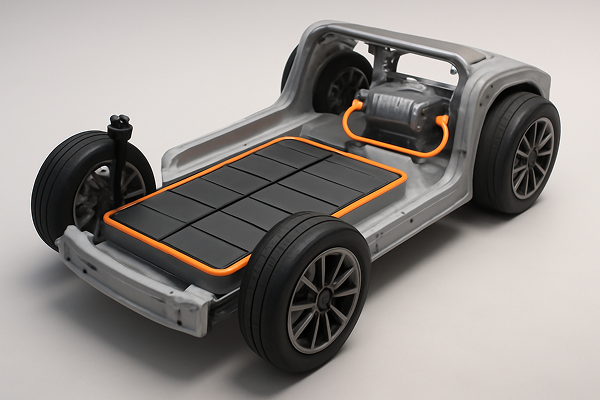

Why is Aluminum Die Casting Critical for Electric Vehicle Components?

The industry’s shift to electric vehicles brings new and difficult design challenges. Traditional materials and processes are often too heavy and cannot meet the unique thermal and structural needs.

Aluminum die casting is critical for EVs because it produces lightweight, strong, and thermally conductive parts. This is essential for battery enclosures6, motor housings7, and power electronics8, directly improving a vehicle’s range and performance.

Lightweighting is everything in the EV world. Every kilogram we can save on the vehicle structure translates directly to longer battery range. This is where aluminum die casting shines. My team and I specialize in these exact components for our Tier 2 clients in Europe and North America. The big three applications are the battery, motor, and power electronics8.

The battery enclosure, or tray, needs to be strong to protect the cells in a crash, but also as light as possible. Die casting allows us to create large, single-piece structural components that meet these needs. For motor housings7, thermal management10 is key. The aluminum alloy itself is great at dissipating heat. Even better, the die casting process lets us design and cast intricate cooling channels11 directly into the housing wall. This advanced thermal management10 is vital for high-performance motors. The same logic applies to housings for inverters and on-board chargers (OBCs), which also need to be light, strong, and cool.

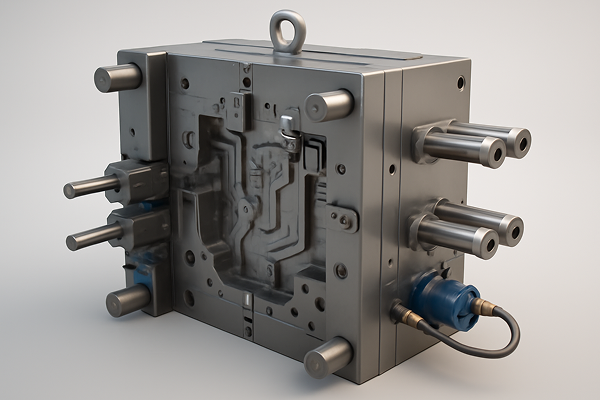

Why is Mold Design the Most Critical Factor in Die Casting Quality?

You approve a final part design, but you still experience quality problems like porosity12. The root cause is often hidden in the mold design13, which is a factor you cannot easily see or inspect.

Mold design is critical because it controls exactly how the molten metal flows, cools, and solidifies. A well-designed mold prevents defects, ensures dimensional accuracy14, and maximizes the tool’s lifespan, directly impacting part quality.

As an engineer, I can tell you that the part quality is won or lost before we ever cut the first piece of steel for the mold. The die itself is an incredibly complex and precise piece of engineering. A great mold does more than just create the part’s shape. It controls the entire process. Key elements we must perfect include:

- Gating and Runners: This is the system that guides the molten metal into the cavity. Its design determines if the flow is smooth or turbulent. Turbulent flow traps air and causes porosity12, which is a major defect.

- Venting and Overflows: These are channels that allow air to escape the cavity as metal rushes in. If air can’t get out, it gets trapped and creates defects.

- Cooling System: The location and size of cooling channels11 inside the mold are critical. They control the cooling rate, which affects the material’s final grain structure and mechanical properties.

Before my team starts building a tool, we run extensive mold flow simulations. This software lets us "see" inside the mold and predict how the metal will behave. For an airtightness part for an Italian customer, our simulation showed that the initial gate location would cause porosity12 right in a critical sealing area. We adjusted the mold design13 based on this data, preventing a costly problem before it ever happened.

Conclusion

High-pressure aluminum die casting is a foundational technology for auto manufacturing. It enables the complex, lightweight parts that are essential for both traditional and electric vehicles, making it a critical process.

-

Explore this link to understand how High-pressure die casting revolutionizes automotive part production. ↩

-

Discover the essential automotive parts that rely on die casting for their production. ↩

-

Find out how die casting is used to create durable and precise transmission cases. ↩ ↩

-

Understand the die casting process for engine blocks and its advantages in automotive design. ↩ ↩

-

Learn about the specific electric vehicle components that benefit from die casting technology. ↩ ↩

-

Explore the importance of die casting in creating lightweight and strong battery enclosures. ↩ ↩ ↩

-

Learn how die casting enhances the performance and design of motor housings. ↩ ↩ ↩ ↩

-

Discover the benefits of die casting in the production of power electronics for vehicles. ↩ ↩ ↩

-

Explore the connection between e-mobility and die casting in the automotive industry. ↩

-

Learn how die casting aids in effective thermal management for electric vehicle components. ↩ ↩

-

Learn about the role of cooling channels in die casting and their impact on part quality. ↩ ↩

-

Find out how to prevent porosity in die casting to ensure high-quality automotive components. ↩ ↩ ↩

-

Understand the significance of mold design in ensuring high-quality die cast parts. ↩ ↩

-

Explore how die casting techniques maintain strict dimensional accuracy in automotive manufacturing. ↩