Choosing the wrong die casting supplier can put your entire project at risk. This leads to costly delays and quality failures. This guide provides a clear framework to vet potential partners.

To choose the right automotive die casting supplier, you must evaluate their quality system certifications like IATF 169491, their PPAP capabilities2, in-house testing facilities3, and their ability to provide deep engineering support4. A true partner helps you from design through to reliable mass production.

The big picture is important, but as a supplier quality engineer or a purchasing director, you know the real story is in the details. What I’ve learned over 20 years in this industry is that you need to ask specific questions about a supplier’s capabilities. Let’s break down the most critical areas you need to investigate to find a partner you can trust for the long term.

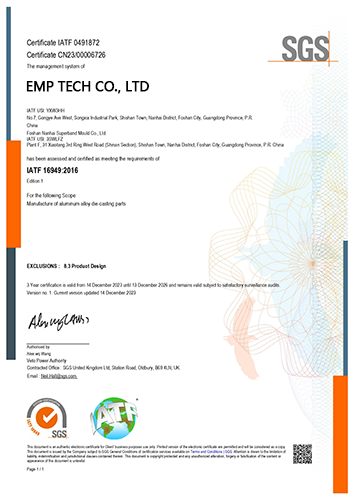

Why is IATF 16949 Certification Non-Negotiable?

Doubting a supplier’s quality processes? This uncertainty can lead to production defects and recalls. A certified quality system is your first line of defense against these risks.

IATF 16949 certification is crucial. It proves a supplier has a robust, audited quality management system5 for the automotive industry6. It ensures consistent processes, risk management7, and continuous improvement8 for your projects.

In my experience, especially when working with German Tier 1s, IATF 16949 is more than just a piece of paper. It is the language of quality in the automotive world. It’s a complete operational mindset. When a supplier tells you they are IATF 16949 certified, it means they have structured systems for everything. It connects the design phase, like with Failure Mode and Effects Analysis (FMEAs), to the production floor with detailed Control Plans. For a Purchasing Director, this certification means significantly lower risk. For a Quality Engineer like Jure, it means we start on the same page, with the same expectations for documentation, process control, and problem-solving. It tells you that the supplier has procedures for handling everything from raw material inspection to how they would manage a process change request. It’s the foundation of a reliable partnership.

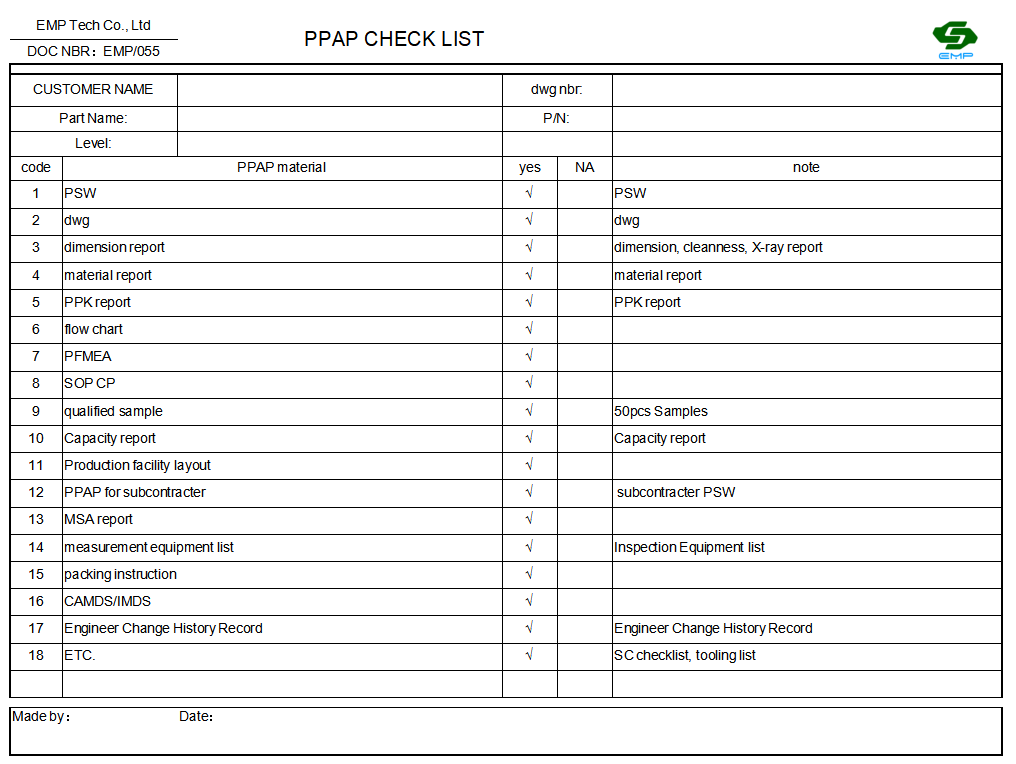

How Critical is a Supplier’s PPAP Capability?

Worried your new part won’t meet spec at launch? A weak PPAP submission leaves you guessing, which risks delays. Robust PPAP capability ensures a smooth start of production.

A supplier’s Production Part Approval Process9 (PPAP) capability is extremely critical. It is the hard evidence that they understand your requirements and that their process can consistently produce parts that meet those requirements.

As an engineer, I see the PPAP as the final exam before mass production begins. It’s not just about filling out paperwork; it’s the culmination of months of development work. When my team and I prepare a PPAP for a client, we are presenting a complete story of the part. This story includes the Process Flow Diagram, the PFMEA which identifies potential risks, and the Control Plan that shows how we mitigate them. The most important parts for die casting are the dimensional results, material certifications, and capability studies (Cpk). I remember a project for a Canadian client’s On-Board Charger (OBC) housing. Our thorough PPAP submission, including detailed CMM layouts and initial capability data, identified a minor tolerance stack-up issue. We caught it and fixed it before it could impact their assembly line, saving them a massive headache and cost. A strong PPAP isn’t a burden; it is your insurance for a successful launch.

What In-House Testing Capabilities Should You Demand?

Blindly trusting a supplier’s quality? Without proof, you risk receiving faulty parts. Demand a supplier with comprehensive in-house testing to verify quality before every shipment.

You should demand in-house testing like CMM for dimensions10, X-ray for internal porosity11, a spectrometer for material analysis12, and leak testing for airtightness13. This shows a real commitment to quality and reduces your own inspection burden.

This is where a supplier proves they are serious about quality. Having the right testing equipment in-house is a game-changer. For the complex new energy vehicle parts we specialize in, it’s not optional. Here’s a breakdown of the essentials:

| Testing Equipment | Why It’s Critical for Automotive Die Casting |

|---|---|

| CMM Machine | Guarantees that all critical dimensions and geometric tolerances (GD&T) are precisely met. |

| X-Ray Machine | Finds internal defects like porosity, which is vital for parts requiring high strength or pressure tightness. |

| Spectrometer | Verifies the aluminum alloy composition of every batch to ensure material integrity and performance. |

| Leak Tester | Essential for sealed components like motor and controller housings that demand high airtightness. |

When we develop a motor controller housing, the part must be both lightweight and strong, but also manage heat. Our in-house X-ray allows us to check for porosity in critical areas in real-time and adjust the die-casting process immediately. This instant feedback loop is something you don’t get if a supplier has to send parts out for testing. It ensures a stable process and gives clients like Jure the confidence that every part shipped meets their strict quality standards.

Does Your Supplier Offer Real Engineering Partnership?

Facing complex design challenges alone? This can lead to un-castable parts and endless revisions. A supplier with strong engineering support helps you optimize your design for manufacturing from day one.

Yes, your supplier must be an engineering partner, not just a parts maker. They should provide DFM analysis, mold flow simulation14, and process optimization ideas. This collaboration saves time, reduces cost, and improves quality.

This is the biggest difference between a simple supplier and a true partner. My role has evolved from a hands-on technician to an engineering consultant because our customers need solutions, not just parts. A true partner gets involved early. When a customer sends us a new design, the first thing my team does is a detailed Design for Manufacturability15 (DFM) analysis. We look for things like uniform wall thickness, proper draft angles, and radii that will ensure a smooth and robust casting process. We recently worked with a U.S. client on a new structural component. The initial design was innovative but had features that would have created defects during casting. Using mold flow simulation14, we showed them exactly where the problems would occur. We then worked together to make small design tweaks that didn’t change the part’s function but made it perfect for high-pressure die casting. This early collaboration saved them from a costly tool modification and months of delays. This is the value we bring beyond just making the part.

Is Your Potential Supplier Ready for a Rigorous Audit?

Unsure if a supplier can pass your audit? A failed audit derails project timelines. You need a supplier who is always audit-ready, transparent, and organized.

A good supplier is always ready for an audit. Their processes should be well-documented, the shop floor clean and organized, and their team prepared to answer questions. This reflects a culture of quality you can rely on.

For an SQE like Jure, an on-site audit is the moment of truth. My team and I welcome audits. We see them as an opportunity to build trust and show our clients how we work. A supplier who is truly audit-ready doesn’t need weeks to prepare. Their quality culture16 is visible every day. When you walk our shop floor, you will see clear work instructions at each station. You will see calibration stickers on all gauges and measurement equipment. You can ask any operator about the quality checks they perform, and they can show you the documentation. One of the most important things we demonstrate during an audit is traceability. We can take any part from our warehouse and trace it all the way back to the specific batch of aluminum ingot it came from, including all the process parameters from that production run. This level of detail and transparency gives our customers peace of mind. It shows that our processes are under control and that we are a partner they can hold accountable.

How Do You Balance Cost Without Sacrificing Quality?

Pressured to cut costs? Choosing the cheapest option often leads to quality issues and higher total costs. The key is to find a supplier who offers value, not just a low price.

You balance cost and quality through value engineering17. A strong partner helps optimize your design, suggests material alternatives, and improves processes to reduce waste. This lowers the total cost of ownership, not just the piece price.

For a Purchasing Director, cost is always a major factor. But my two decades on the shop floor have taught me that the cheapest quote is often the most expensive one in the long run. The real goal is to find the best value. This is where value engineering comes in. A proactive supplier doesn’t just give you a price on the drawing you send. They look for ways to make the part better and more efficiently. For example, we often analyze a part’s design and suggest a small change to a non-critical feature. This change might allow us to design a more efficient mold or reduce the casting cycle time18 by a few seconds. Those few seconds, over a run of hundreds of thousands of parts, add up to significant savings. This approach reduces the piece price while also improving delivery stability. It’s about looking at the Total Cost of Ownership—factoring in quality, delivery, and engineering support—not just the initial price tag.

Can the Supplier Grow With Your Project’s Demands?

Worried your supplier can’t handle your volume ramp-up? This can halt your production line. You need a partner with proven capacity and a clear plan for scalability.

A supplier must show both current capacity and a clear plan for scalability. Ask about their press tonnage range and utilization rates. This ensures they can support your project from prototype to full production.

When you are launching a new vehicle program, you need to be certain your supplier can keep up as demand grows. This is a critical conversation for both purchasing and quality. The first question to ask is about their equipment. At EMP, our die casting machines range from 350 tons to 3,500 tons. This means we can produce everything from small electrical housings to large, complex structural parts for EV chassis. But capacity isn’t just about having machines. It’s about how you manage them. We show our clients our production planning system and current utilization rates. More importantly, we discuss how we will reserve capacity for their project ramp-up. This involves planning for tooling, dedicating specific manufacturing cells, and training operators well in advance of the start of production. This proactive planning ensures a smooth transition from low-volume builds to high-volume mass production without any surprises or delays.

How Can You Be Sure of On-Time Deliveries?

Stressed about late shipments disrupting your assembly line? Unreliable suppliers create chaos. You need a partner with a proven track record of delivery performance and a reliable supply chain.

Look for a supplier’s On-Time Delivery (OTD) metrics. Ask about their inventory strategies for raw materials and finished goods. A reliable supply chain is built on transparent communication and proactive logistical planning.

A high-quality part that arrives late is still a problem. Supply chain reliability is just as important as part quality. For our global customers in places like Germany, Italy, and the United States, a missed delivery can shut down their entire assembly plant. That’s why we treat logistics with the same seriousness as we do engineering. It starts with managing our own supply chain. We maintain a strategic inventory of primary aluminum ingots to protect against market shortages or price spikes. We also have a clear system for managing finished goods. For some long-term projects, we work with the client to establish a safety stock level that buffers against any unexpected transit delays. The key is communication. Our project managers provide regular updates on production status and shipping schedules so our clients always know where their parts are. This transparency and proactive planning create a predictable and dependable supply chain you can count on.

Does Your Supplier Truly Understand Aluminum Alloys?

Using the wrong alloy for your part? This can cause failures in the field. You need a supplier with deep material expertise to help you select the optimal alloy.

A supplier’s material expertise is critical. They should understand various aluminum alloys (like AlSi9Cu3 or AlSi10Mg) and guide you to the best choice for your application, balancing all performance needs.

Not all aluminum is the same. Choosing the correct alloy is one of the most important decisions in the entire process, and your supplier should be your expert guide. The choice impacts strength, corrosion resistance, thermal conductivity, and final cost. As specialists in die casting, we live and breathe these materials. An engineer might come to us with a design for a housing that requires high airtightness. We know from experience that an alloy like AlSi9Cu3(Fe) offers excellent castability and pressure tightness. For a structural part that needs high ductility, we might recommend a different specialized alloy. We use our in-house spectrometer to verify every single batch of raw material before it enters our foundry. This guarantees that the material’s properties are exactly what your application requires. Helping our clients choose the right material is a core part of our engineering support.

| Common Alloy | Key Characteristics | Typical Application |

|---|---|---|

| ADC12 / A380 | Good balance of castability, mechanical properties, and cost. | General purpose housings, engine brackets. |

| AlSi10Mg | Excellent strength, hardness, and thermal conductivity. | Heat sinks, motor housings, complex structural parts. |

| AlSi9Cu3(Fe) | Very good castability and pressure tightness. | Hydraulic components, parts needing to be airtight. |

Conclusion

Choosing the right die casting partner is a critical decision. By focusing on quality systems, technical partnership, and supply chain reliability, you can secure a successful project and strong supplier relationship.

-

Understanding IATF 16949 certification can help you ensure your supplier meets industry quality standards. ↩

-

Exploring PPAP capabilities can reveal how suppliers ensure parts meet specifications before production. ↩

-

In-house testing facilities can significantly enhance quality assurance and reduce inspection burdens. ↩

-

Deep engineering support can optimize designs and improve manufacturing processes, saving time and costs. ↩

-

A robust quality management system is key to ensuring consistent quality and risk management. ↩

-

Staying updated on automotive industry trends can inform your supplier selection and strategy. ↩

-

Effective risk management practices can prevent costly defects and production delays. ↩

-

Continuous improvement is essential for maintaining high standards and adapting to changes. ↩

-

Learning about PPAP can help you understand how suppliers validate their production processes. ↩

-

CMM machines are essential for verifying critical dimensions, ensuring parts meet specifications. ↩

-

X-ray testing is vital for detecting internal defects, ensuring the strength and reliability of parts. ↩

-

A spectrometer ensures material integrity, which is crucial for performance in automotive applications. ↩

-

Leak testing is essential for components that require high airtightness, ensuring functionality. ↩

-

Mold flow simulation identifies potential casting issues early, saving time and resources. ↩ ↩

-

DFM helps optimize designs for production, reducing costs and improving quality. ↩

-

A strong quality culture fosters trust and reliability in supplier partnerships. ↩

-

Explore how value engineering can optimize costs while maintaining quality, ensuring better project outcomes. ↩

-

Discover how optimizing casting cycle time can significantly reduce production costs. ↩