Engineers are constantly pushed to make cars lighter and more efficient. Traditional heavy materials limit performance, so they need a better solution. Aluminum casting is the answer for modern vehicles.

The two primary reasons are its lightweight nature, which boosts fuel efficiency and EV range, and its excellent design flexibility. The casting process allows for the creation of complex, integrated parts that are both strong and cost-effective, which other methods can’t match.

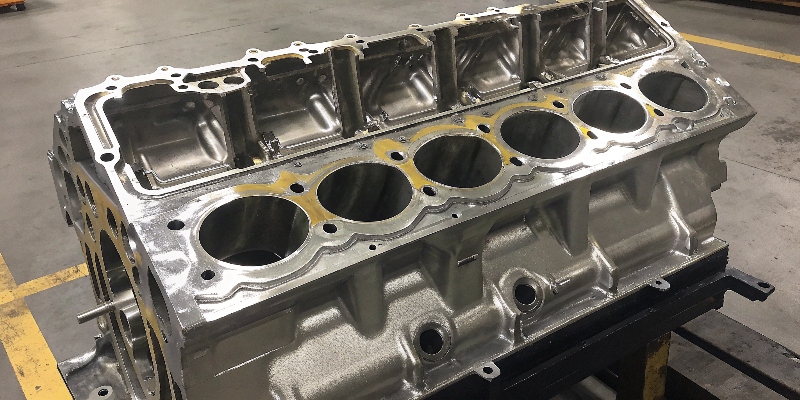

In my two decades working with automotive parts, I’ve seen the shift to aluminum firsthand. This material has become a cornerstone of modern vehicle design, from the engine block to the battery housing1. It’s not just about one benefit; it’s about how these advantages work together. Let’s break down exactly why aluminum has become so critical for the cars we drive today.

How Does Aluminum’s Lightweight Advantage Boost Fuel Efficiency and EV Range?

Every gram counts when designing a vehicle. Heavy components hurt performance, especially for EVs where the battery is already a huge challenge. Aluminum offers a direct path to better efficiency.

Aluminum is about one-third the density of steel. Using aluminum castings for key parts reduces a vehicle’s total weight. This means less energy is needed for acceleration, improving MPG in gasoline cars or extending battery range in electric vehicles.

The simple fact is that it takes less energy to move a lighter object. This basic principle of physics is the driving force behind the automotive industry’s focus on lightweighting. I’ve spent my career helping customers leverage this principle with aluminum die casting. A lighter car creates a positive feedback loop. When you reduce the weight of the body and chassis, you can use a smaller, lighter engine or battery to get the same performance. This, in turn, makes the vehicle even lighter.

The Impact on Internal Combustion Engines (ICE)

For traditional cars, less weight means the engine doesn’t have to work as hard. This directly improves fuel economy (MPG or L/100km). It also improves handling, braking, and acceleration, making the car feel more responsive and safer to drive. A lighter frame puts less stress on suspension components, which can improve durability.

The Critical Role in Electric Vehicles (EVs)

In the world of EVs, weight is even more critical. The battery is the heaviest and most expensive component. By reducing the weight of parts like the motor housing, battery enclosure, and structural components, you can extend the vehicle’s range with the same size battery. On a recent EV motor controller housing project, my team and I helped a customer achieve a 40% weight reduction compared to their previous stamped steel design. This single change contributed to a noticeable increase in the vehicle’s overall range.

| Property | Steel (Typical) | Aluminum Alloy (A380) | Advantage |

|---|---|---|---|

| Density | ~7.85 g/cm³ | ~2.7 g/cm³ | ~65% Lighter |

| Effect on Range/MPG | Baseline | Increased | Less energy needed |

| Handling | Slower response | More agile | Improved safety |

Why Is Design Flexibility a Key Advantage of Aluminum Casting?

Manufacturing many separate parts and then assembling them is slow, expensive, and complex. Each joint or fastener is a potential point of failure and adds weight to the final product.

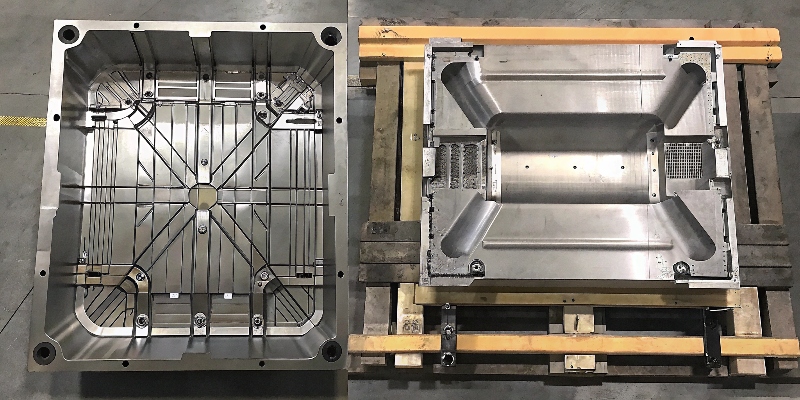

Aluminum casting, especially high-pressure die casting, allows engineers to design intricate, one-piece parts that can’t be made with stamping or machining. This allows for part consolidation, which reduces assembly costs, weight, and potential quality issues.

The ability to create complex shapes is where aluminum casting really shines. When I work with engineering teams from major automotive suppliers, their biggest challenges are often related to packaging. They need to fit more technology into smaller spaces without adding weight or cost. High-pressure die casting gives us the tools to solve these problems. We can design parts with very thin walls, integrated cooling channels, and complex internal structures that would be impossible to create otherwise.

Part Consolidation in Action

Part consolidation is the process of redesigning a multi-part assembly into a single, integrated component. For example, a traditional motor housing might consist of a stamped metal body, a separate machined flange, and several welded brackets for mounting. With die casting, we can combine all of these features into one piece. This eliminates the need for welding, seals, and fasteners between those parts. The result is a lighter, stronger part that is faster to produce and has fewer potential leak paths or points of failure.

Achieving Complex Geometries

Die casting allows us to create features with incredible detail. We can design in cooling fins to manage heat, bosses for mounting electronics, and intricate channels for liquid cooling—all within a single casting. This level of integration is critical for modern EV components like OBC (On-Board Charger) housings and motor controllers, where thermal management2 and compact design are essential. My team uses DFM (Design for Manufacturability) analysis and mold flow simulation to ensure even the most complex designs can be produced consistently and reliably.

| Approach | Multi-Part Steel Assembly | Single Aluminum Casting |

|---|---|---|

| Part Count | 5-10+ parts | 1 part |

| Assembly Process | Stamping, welding, fasteners | None |

| Potential Failure Points | Welds, seals, bolts | Minimized |

| Weight | Higher | Lower |

Conclusion

Aluminum castings are essential in modern automotive design. They provide the perfect combination of weight reduction for efficiency and the design freedom needed to build the complex vehicles of today.