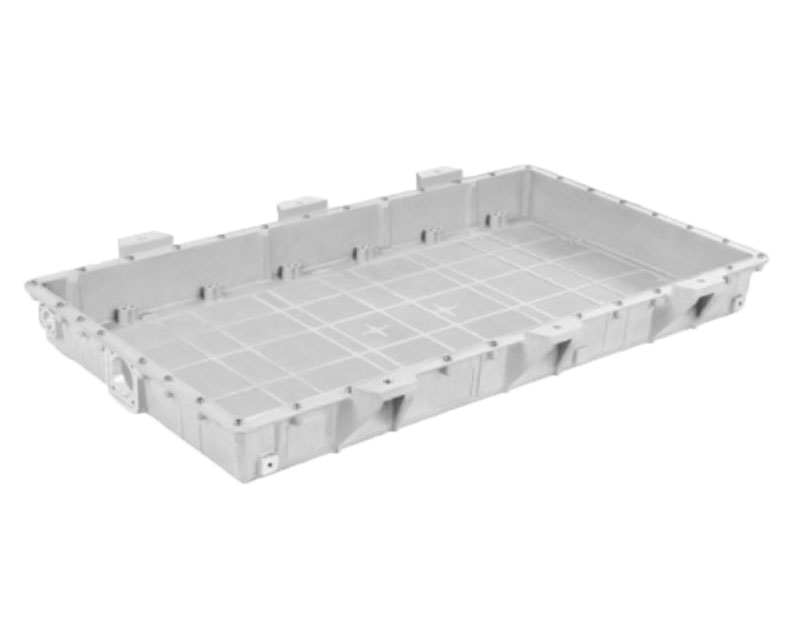

Electric Vehicle Battery Case

In NEVs, the EV battery case is a key structural component that protects the battery pack and reinforces the vehicle body. EMP Tech produces high-performance aluminum alloy battery cases that offer:

Lightweight strength for structural support

Efficient heat dissipation and thermal stability

Corrosion and impact resistance

High electrical conductivity for grounding and shielding

Using large-scale vacuum die casting, we achieve thin-wall, high-precision parts with porosity <0.1% and IP67 sealing. Our end-to-end engineering—from DFM to PPAP—ensures reliable quality and accelerated project timelines for global EV programs.

Specification

Lightweight Composite Battery Enclosures for EVs: 40% Lighter, Quieter & Safer

The shift to composite materials for electric vehicle (EV) battery enclosures offers three key advantages over traditional aluminum or steel:

1. 40% Weight Reduction

Replacing aluminum with advanced composites can reduce battery shell weight by up to 40%, improving EV range, efficiency, and scalability.

2. Enhanced Noise Reduction

Composite materials dampen vibrations more effectively than metal, reducing cabin noise for a smoother, quieter driving experience—a critical factor in commercial EVs and premium models.

3. Superior Safety & Structural Strength

Composite battery enclosures provide higher strength and stiffness than aluminum or steel. When integrated into the vehicle’s structure, they protect both the battery and passengers in collisions.

Scalable Production with Pultrusion

To meet mass-production demands, pultrusion enables high-speed, cost-effective manufacturing of lightweight yet ultra-strong composite components—key for affordable, high-performance EVs.

Production Process

Please fill in the form and our professionals will contact you within 12 hours!

+86 18033163576