Electric vehicles (EVs) are revolutionizing the automotive industry, and one of the critical components powering this transformation is the battery. But what keeps these batteries safe and efficient? That’s where the EV battery enclosure comes into play. These enclosures not only protect the batteries but also help ensure that they operate efficiently in a variety of conditions. In this article, we will dive deep into what EV battery enclosures are, why they're important, and what goes into their design and functionality.

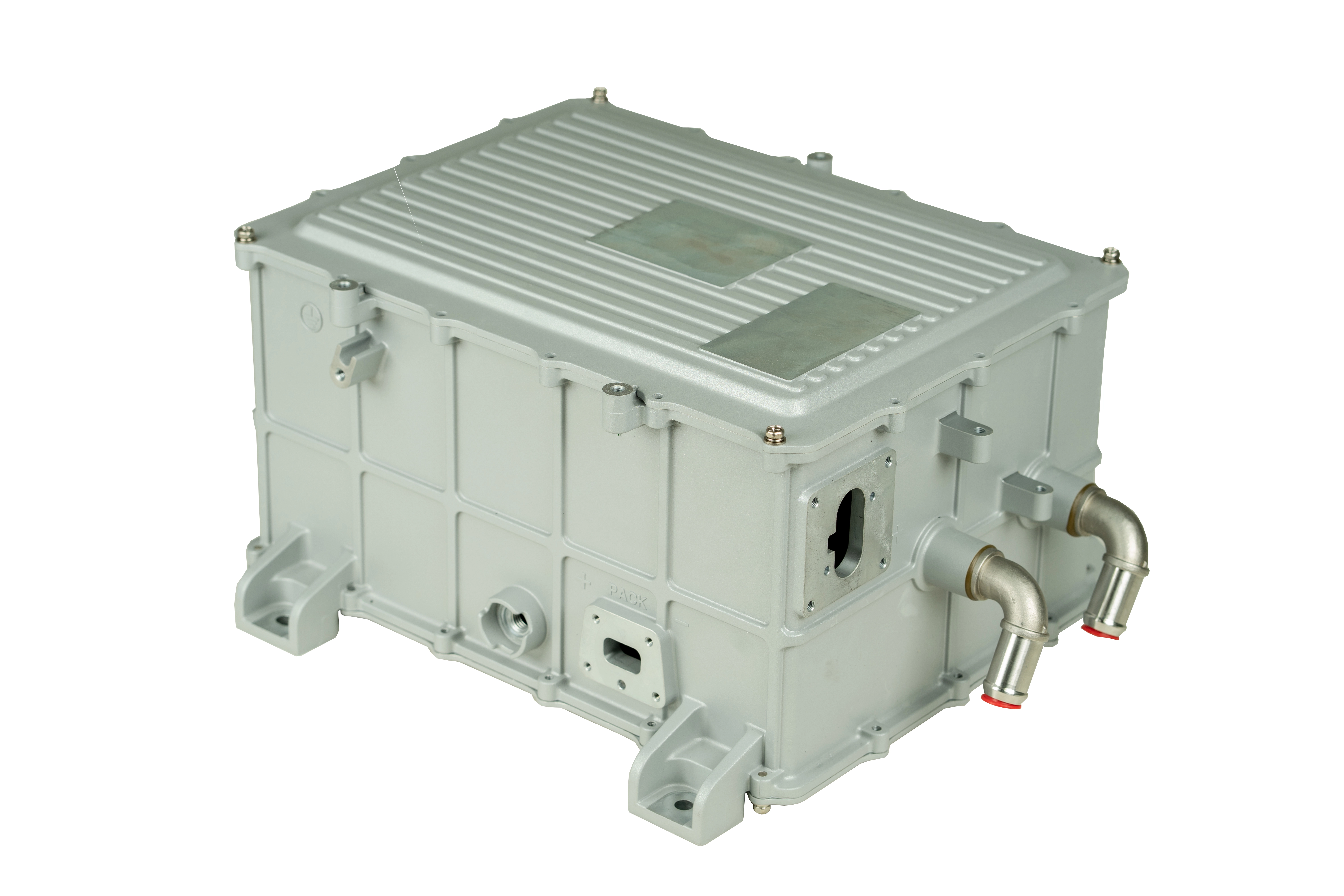

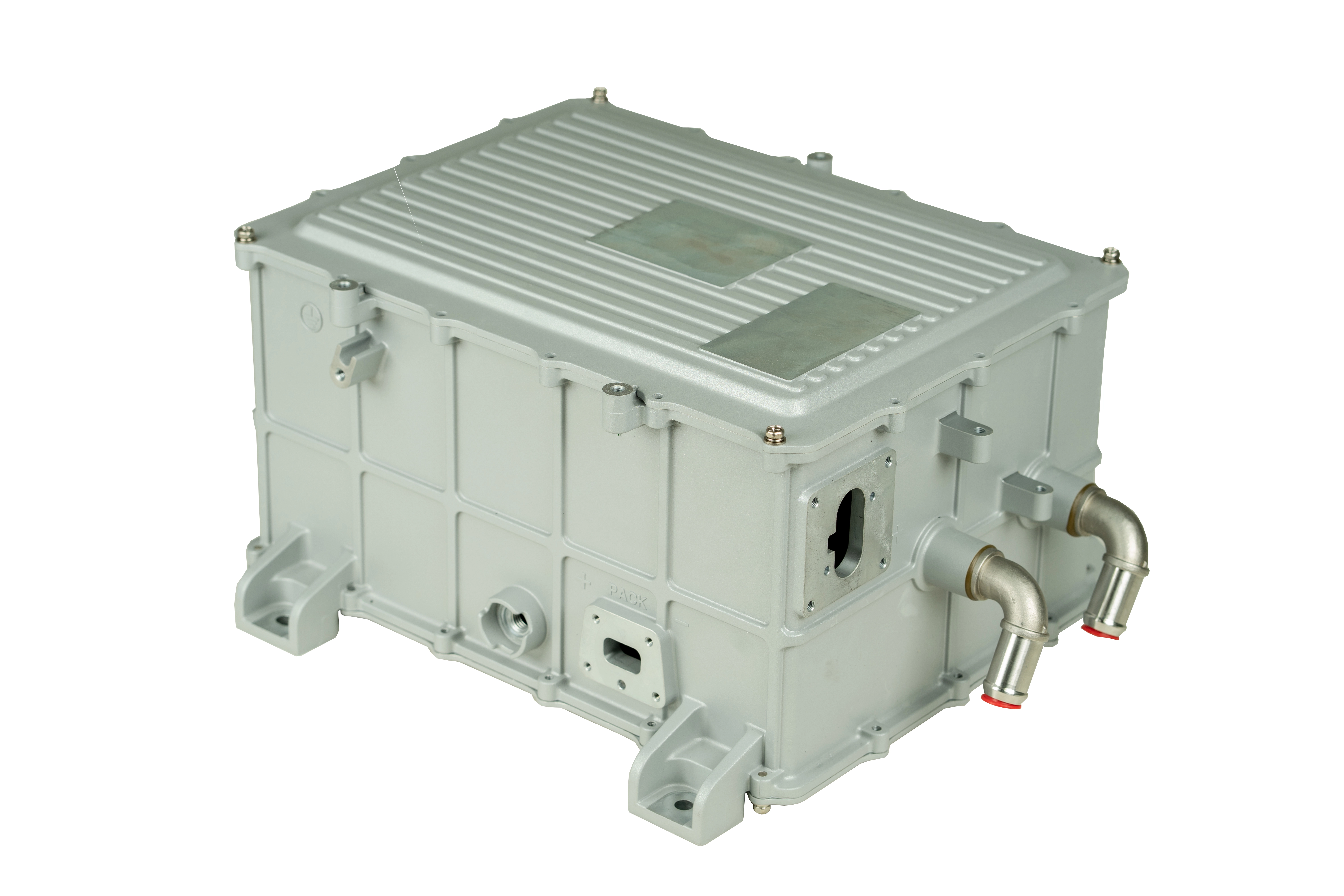

EV battery enclosures are essentially protective shells that house and safeguard the battery pack within an electric vehicle. Their primary role is to shield the battery from external factors such as extreme weather, dust, water, and physical impacts. But that's just the beginning. These enclosures also play a crucial part in managing heat, providing structural integrity, and enhancing the overall safety of the EV. Without a proper battery enclosure, EVs would be prone to overheating, damage from external factors, and even catastrophic failures.

Metals: The most common materials for battery enclosures are metals like aluminum and steel. Aluminum, being lightweight and corrosion-resistant, is a popular choice. Steel, on the other hand, is heavier but offers superior strength and durability.

Composites and Plastics: As technology advances, manufacturers are experimenting with composites and plastics. These materials offer the possibility of reducing weight even further, while also providing a degree of flexibility in design. They may not be as durable as metals but are being used increasingly in low-cost, high-volume electric vehicles.

Structural Integrity and Weight Optimization: The enclosure must be strong enough to protect the battery from impacts, yet light enough to not significantly affect the overall weight of the vehicle. This balance is crucial for performance and efficiency.

Space Efficiency: The enclosure must be designed to house the battery in a compact, space-efficient manner. In many cases, this means designing the enclosure to fit irregularly shaped or unusually sized battery packs.

Temperature Control and Insulation: The battery enclosure must also offer insulation and efficient airflow, to keep the battery within the optimal operating temperature range.

Cooling Systems: Most EV battery enclosures incorporate cooling systems, which can either use liquid or air to dissipate heat. Liquid cooling systems are more efficient but are often more complex and expensive to maintain. Air cooling is simpler but less effective in extreme conditions.

Heat Dissipation Features: Modern battery enclosures are designed with materials and structures that aid in dissipating heat away from the battery pack, ensuring the vehicle performs optimally.

Crash Safety: In the event of an accident, the battery enclosure must be able to withstand impact and prevent damage to the battery, which could lead to fires or leaks.

Waterproofing and Dustproofing: EV battery enclosures also need to be sealed to prevent water or dust from entering and damaging the battery. This is particularly important for vehicles used in rugged or off-road environments.

Range and Efficiency: A well-designed enclosure helps improve the overall efficiency of the battery, which can extend the vehicle's range.

Charging Times: Proper thermal management within the enclosure can also reduce the time it takes to charge the battery, making the vehicle more convenient for everyday use.

Battery Longevity: With effective protection and temperature control, battery enclosures help extend the lifespan of the battery, reducing the need for replacements over time.

Designing and manufacturing an EV battery enclosure is no easy feat. Manufacturers must ensure precision in design and production, often working with complex materials and technologies. Additionally, quality control is critical—battery enclosures must undergo rigorous testing to ensure they meet safety standards and perform reliably in real-world conditions.

Advanced Materials: New materials like carbon fiber composites may become more common, offering better strength-to-weight ratios and improved safety.

Integrated Technologies: Future enclosures might include more integrated technologies like sensors for real-time monitoring of battery health and temperature.

Sustainability: With an increasing focus on sustainability, manufacturers are looking at eco-friendly materials and manufacturing processes for battery enclosures.

Enhanced Performance: Proper enclosures help the battery perform efficiently, increasing the vehicle's range and overall driving experience.

Reduced Risk of Damage: A well-designed enclosure protects the battery from external damage, reducing the risk of expensive repairs or replacements.

Increased Vehicle Lifespan: By preventing battery degradation and protecting against external factors, high-quality enclosures help increase the overall lifespan of both the vehicle and the battery.

While high-quality battery enclosures offer numerous benefits, they also come with a cost. Factors such as material choice, design complexity, and manufacturing processes contribute to the final price of the enclosure. However, as demand for electric vehicles rises, economies of scale may drive down costs over time.

The design of the battery enclosure can significantly affect the overall design of the vehicle. From the size and placement of the battery pack to the aerodynamics of the vehicle, the battery enclosure plays a central role in shaping the vehicle’s overall look and performance.

Several companies specialize in the design and production of EV battery enclosures. These manufacturers are constantly innovating, focusing on improving the safety, performance, and cost-efficiency of their products. Companies such as Tesla, Panasonic, LG Chem and EMP Casting are major players in the industry, driving advancements in battery and enclosure technologies.