Hybrid technology is at the forefront of modern engineering, bridging the gap between traditional systems and cutting-edge advancements in electrification. At EMP Casting, we are committed to delivering superior hybrid components that cater to the evolving demands of the automotive and industrial sectors.

The Role of Hybrid Systems in Modern Industries

Hybrid systems integrate conventional and innovative technologies to achieve optimal performance, energy efficiency, and reduced emissions. Industries such as automotive, aerospace, and energy generation are increasingly adopting hybrid solutions to meet sustainability and efficiency goals. Our expertise lies in producing high-performance components that empower these systems to operate seamlessly.

Advanced Manufacturing Techniques for Hybrid Components

To meet the exacting standards of hybrid systems, precision and innovation are paramount. Our state-of-the-art manufacturing facilities leverage:

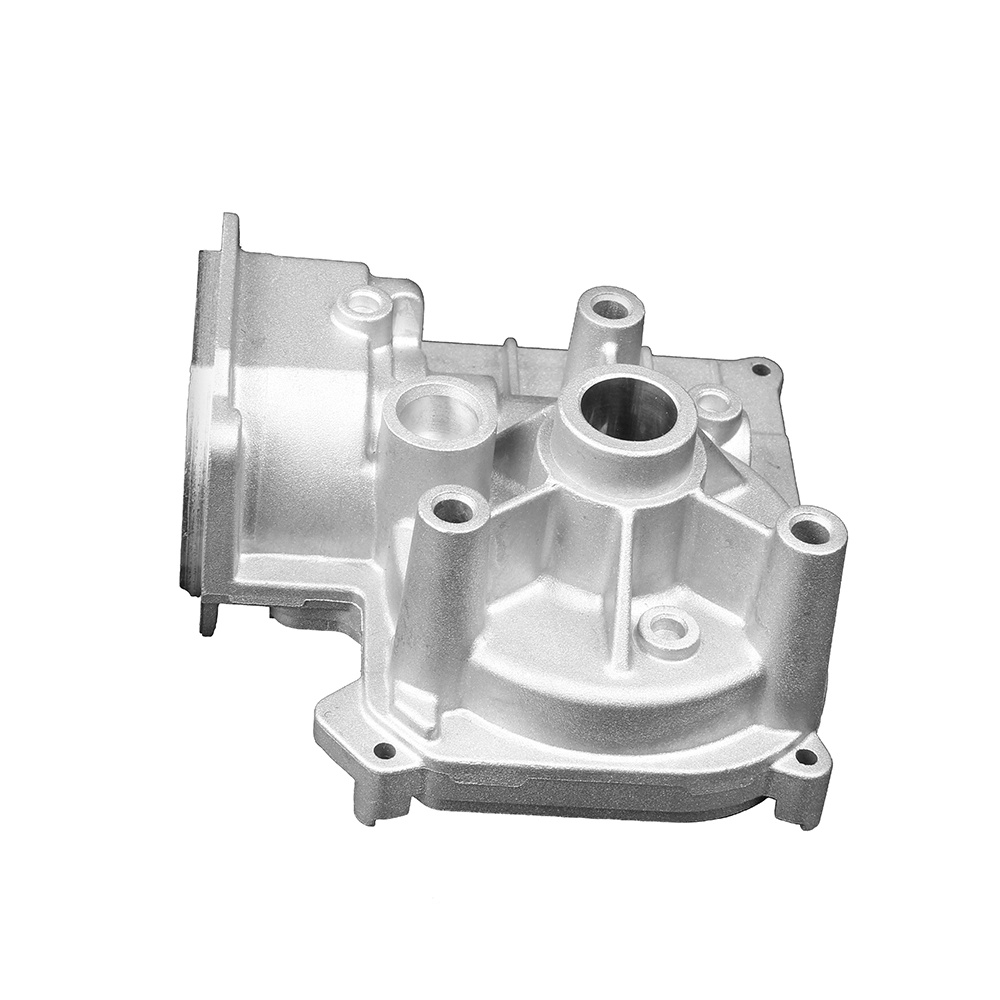

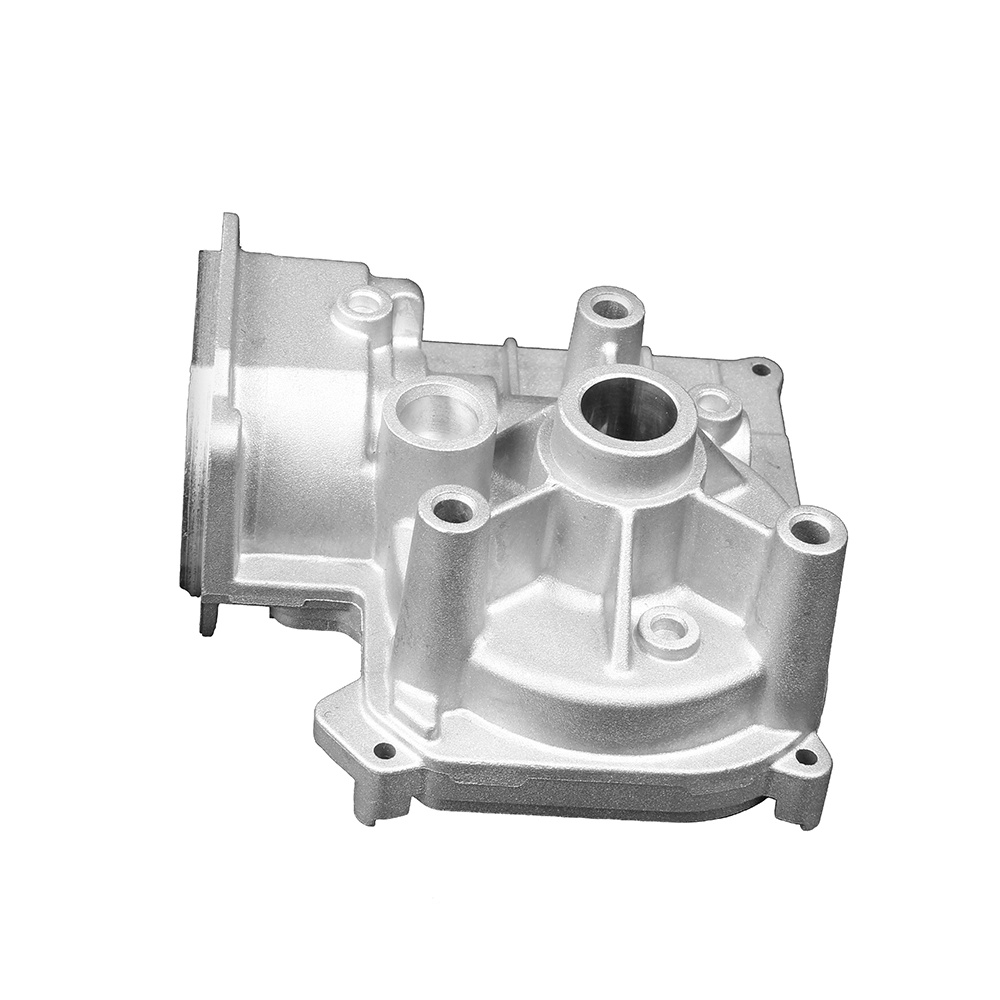

1. Die-Casting for Lightweight Durability

Die-casting offers unmatched precision in producing lightweight components essential for hybrid applications. Using advanced alloys like aluminum and magnesium, we ensure:

High thermal conductivity for improved system cooling.

Exceptional strength-to-weight ratios for enhanced fuel efficiency.

Precise geometries that support complex designs.

2. Additive Manufacturing for Customization

3D printing enables rapid prototyping and the production of customized components tailored to specific hybrid system requirements. Key benefits include:

Reduced lead times for part development.

Enhanced design flexibility for complex geometries.

Minimal material waste, supporting sustainable practices.

3. Surface Treatment for Enhanced Durability

Hybrid components often operate in challenging environments. Advanced surface treatments, such as anodizing and PVD (Physical Vapor Deposition), ensure:

Corrosion resistance to extend component life.

Enhanced wear resistance for demanding applications.

Improved thermal and electrical conductivity.

Key Hybrid Component Offerings

Our portfolio includes an array of components designed to optimize hybrid system performance:

1. Electric Motor Housings

Precision-engineered housings that ensure efficient heat dissipation and structural integrity, supporting high-speed electric motors.

2. Battery Casings

Lightweight, robust casings that safeguard lithium-ion and solid-state batteries, offering thermal management and impact resistance.

3. Power Electronics Enclosures

Compact, thermally efficient enclosures that protect sensitive electronics from environmental factors while ensuring optimal performance.

Sustainability in Hybrid Component Manufacturing

We prioritize sustainability by integrating eco-friendly practices at every stage of production. This includes:

Utilizing recycled materials without compromising quality.

Adopting energy-efficient manufacturing processes.

Minimizing waste through lean production methodologies.

Future Trends in Hybrid Component Innovation

The hybrid industry is poised for significant advancements driven by:

1. Increased Adoption of Solid-State Batteries

Solid-state batteries offer higher energy densities and improved safety compared to traditional lithium-ion batteries. Our manufacturing processes are geared to support this transition with advanced casing and thermal management solutions.

2. Integration of AI in Manufacturing

Artificial intelligence is transforming production by enabling predictive maintenance, optimizing workflows, and ensuring quality control.

3. Focus on Circular Economy Principles

We are developing strategies to enhance recyclability and reduce the environmental footprint of hybrid components, aligning with global sustainability goals.

Why Choose Us for Hybrid Component Manufacturing

With decades of experience and a relentless commitment to innovation, we are the trusted partner for industries seeking top-tier hybrid solutions. Our comprehensive approach ensures:

Precision engineering tailored to your needs.

Timely delivery and exceptional customer support.

Solutions that align with your sustainability objectives.

Partner with us to drive the future of hybrid technology. Contact us today to learn how our expertise can transform your operations.