Precision Aluminum Die Casting Solutions

Trusted by Tier 1 & OEMs

Backed by 20+ years of die casting expertise and IATF 16949 compliance, EMP Tech delivers lightweight, airtight, and high-precision parts for mission-critical applications.

Why Tier 1 Suppliers Choose EMP

One-Stop Solution

From die casting and CNC machining to finishing and testing, we handle all production steps in-house. No more juggling multiple vendors or supply chain headaches.

Engineering Expertise

Over 30 years serving automotive, telecom, EV and industrial clients. Our team optimizes your design for cost, weight and performance, ensuring OEM-quality results.

Fast Turnaround

Competitive lead times (40-day tooling) and high capacity (335k parts/month). Our wide machine range (350T–3050T) and low MOQ let you scale production quickly.

Quality & Compliance

ISO 9001 and IATF 16949 certified, VDA 6.4 audited, CBAM and ISO 14001 compliant. Your parts arrive ready-to-use with the reliability required by global OEMs.

Quality Performance Metrics

99.8%

First Pass Yield

Zero-defect production rate

±0.05mm

100%

24h

Proven By Projects

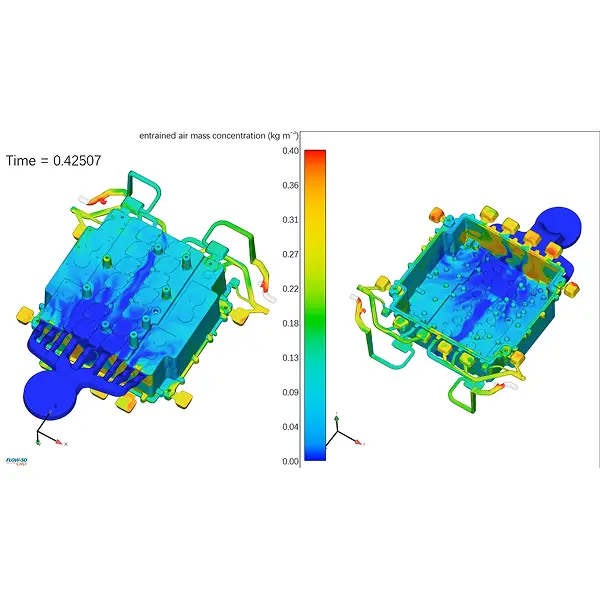

Potential risk of porosity in thin-wall die casting parts

Porosity rate < 0.3%; able to achieve seamless welding of 3-Millimeters thin-walled parts for new energy vehicles. No risk of cracking or leakage under on-site installation.

Required to pass IP68 waterproof test

All external interfaces have passed 100% IP68 leakage test; no vibration or fatigue cracks after vibration durability testing.

FSW sealing and CNC precision required

Connector (head and base) weld strength pass rate >90%; no need for secondary assembly, fewer components, reduced risk of excessive weight and increased reliability.

High cleanliness in line with VDA 19.1 / ISO 16232 standards

Complies with VDA 19.1/ISO 16232 standards; can be delivered directly with customer packaging (no need for re-cleaning).

350 – 3500T high-pressure die casting: professional capacity planning, mold flow analysis, risk identification and optimization. Ensures internal product quality and consistency, 100% air tightness testing.

Advanced friction stir welding (FSW) equipment, process traceability, weld quality risk identification. High-precision 3-axis, 4-axis, 5-axis CNC machining, and professional fixture/tooling design.

Ultrasonic cleaning meets high cleanliness specifications.

Certifications & Quality Control

Trusted by Global Customers

We're There Every Step of The Way

01

Molding

Using simulation technology and database, realize the whole process of digital analysis, design and verification. Tooling longevity exceeds 300k cycles with ±0.02mm tolerance .

02

Die Casting

- TOSHIBA

- LK

- YIZUMI

- UBE

- 350T

- 400T - 2500T

- 1650T

- 3050T

Friction welding enables seamless Al-steel bonding (joint strength ≥90% base metal ), ideal for EV hybrid-material housings.

03

CNC Machining

- Horizontal machining center

- Mazak/Komatsu/BT50 spindle

- Equipment accuracy 0.002mm

04

Automation Finishing

The factory is equipped with automatic polishing robots, which ensures high production efficiency and high yield rate.

05

Shipping

With a mature logistics system and abundant logistics route resources, we can deliver goods with the best solution.

Factory Insights

Ready to Take Your Aluminum Die Casting Project to the Next Level?

Whether you’re solving tight tolerance challenges, managing aggressive timelines, or sourcing high-integrity castings — EMP Tech is here to help. Submit your RFQ today and get expert feedback within 24 hours.